Medical polyurethane catheter

A polyurethane and catheter technology, applied in catheters and other directions, can solve the problems of insufficient comprehensive performance, flattening the tube body, easy precipitation on the surface, etc., to avoid the twisting and knotting of the catheter, reduce arrhythmia, and improve the hardness and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preparation of the medical polyurethane catheter of the present invention is to blend the polyurethane A and the polyurethane B according to the ratio of 7:3, and then extrude and form it through a precision extruder, so that the extruded catheter is stable and stable in size.

[0013] The barium sulfate component in the above-mentioned polyurethane A accounts for 20% of the total amount. The grade of this product is GMTPU01001A and its hardness is 55D.

[0014] The barium sulfate component in the above-mentioned polyurethane B accounts for 40% of the total amount. The grade of this product is GMTPU01002A and its hardness is 65D.

[0015] As a filler of polyurethane, barium sulfate improves the comprehensive performance of polyurethane.

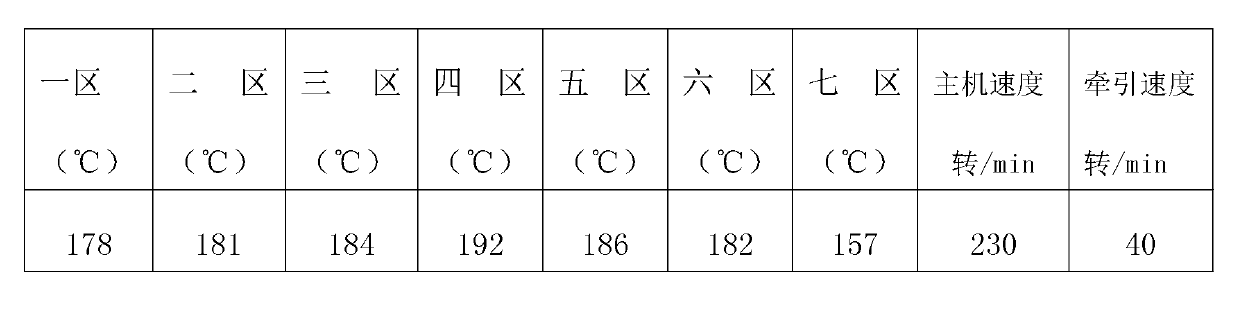

[0016] The catheter is tested with a precision extruder. The main parameters include a temperature control system with 7 zones, a servo-controlled host speed, a precision blowing system, and a high-precision traction and cutting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com