Half-die forging method and device for large-scale marine crank throw

A half-die forging and crank-turn technology, applied in the field of forging, can solve the problems of increasing the smelting cost of raw materials, unfavorable mass production of crankshafts, and large remaining blocks of crank pins, so as to shorten the production cycle, reduce capital investment, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

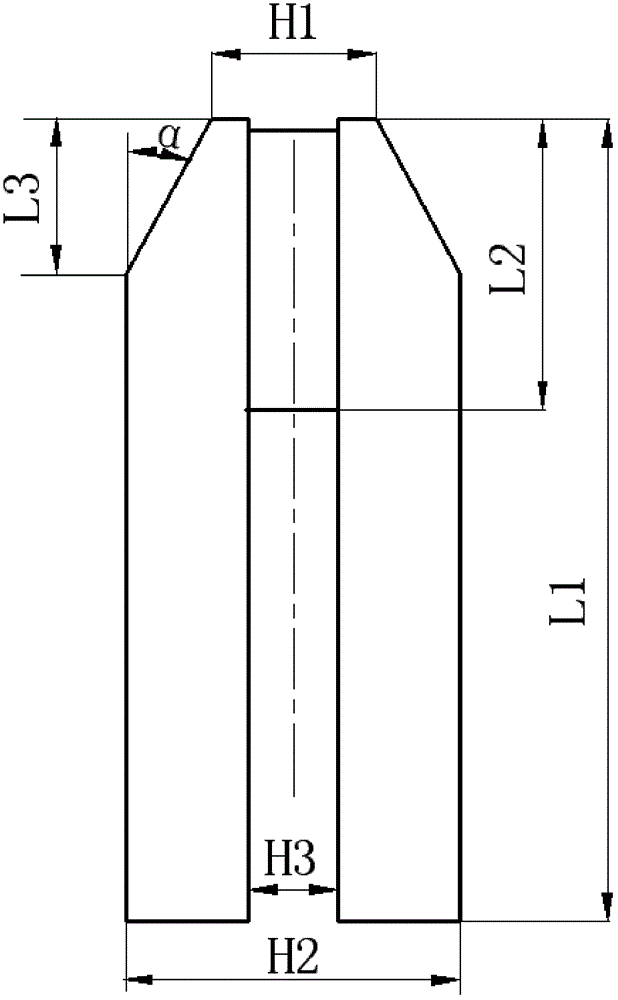

[0047] The semi-die forging device of the large-scale marine crank throw provided by the present invention includes a bending forging upper die 9, a bending forging lower die 7, an upper flat anvil 3, a lower flat anvil 5, and an inserting plate 10, which clamp two symmetrical sides of the side of the blank. Press card round die 2, a bellcrank pin part molding die 6.

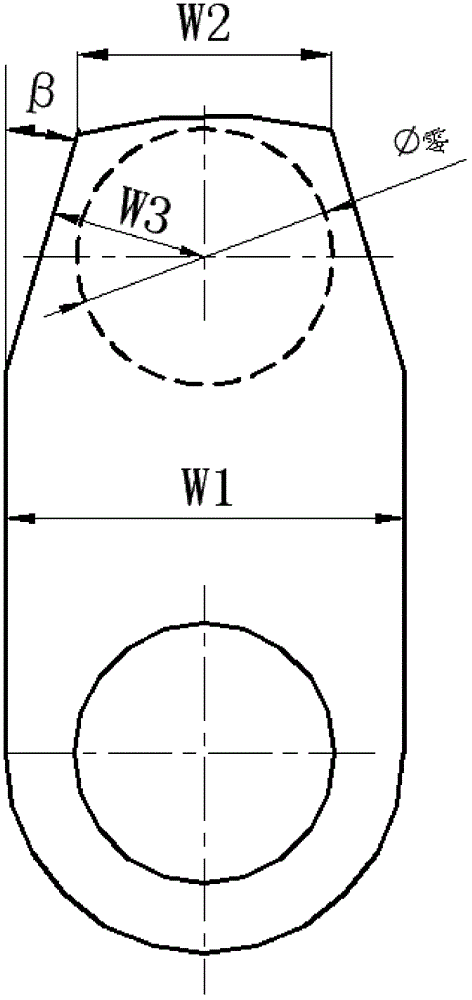

[0048] Such as Figure 3a , Figure 3b As shown, the side pressing round die 2 includes a top mold and a clamping mold of an integral structure, the length of the top mold and the clamping mold is the same, and the clamping mold is located in the middle of the top mold, and the side pressing round mold 2 has an arc shape Concave surface, the arc-shaped concave surface is located in the middle of the card mold, and its angle is less than or equal to 180°, and the side of the top mold close to the arc-shaped concave surface includes a section of inclined surface from top to bottom.

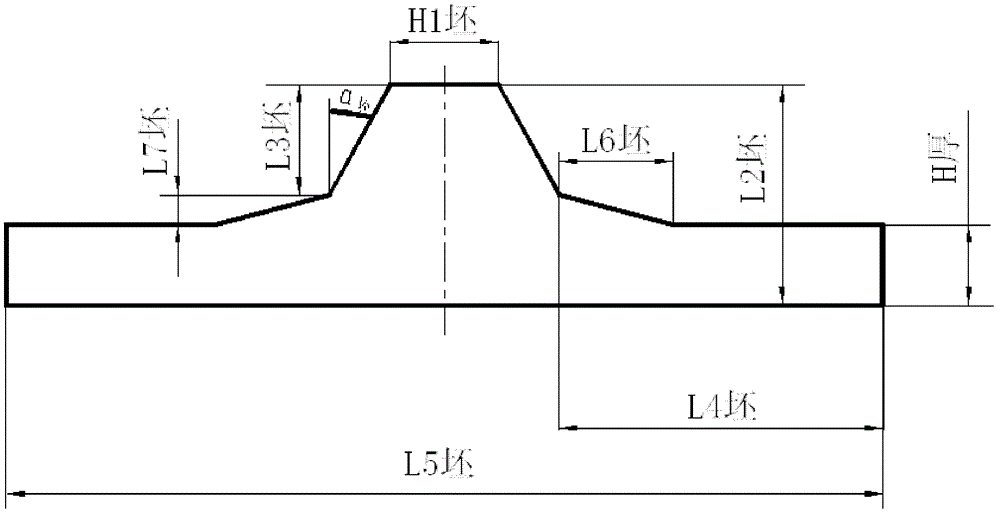

[0049] Such as Figures 6a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com