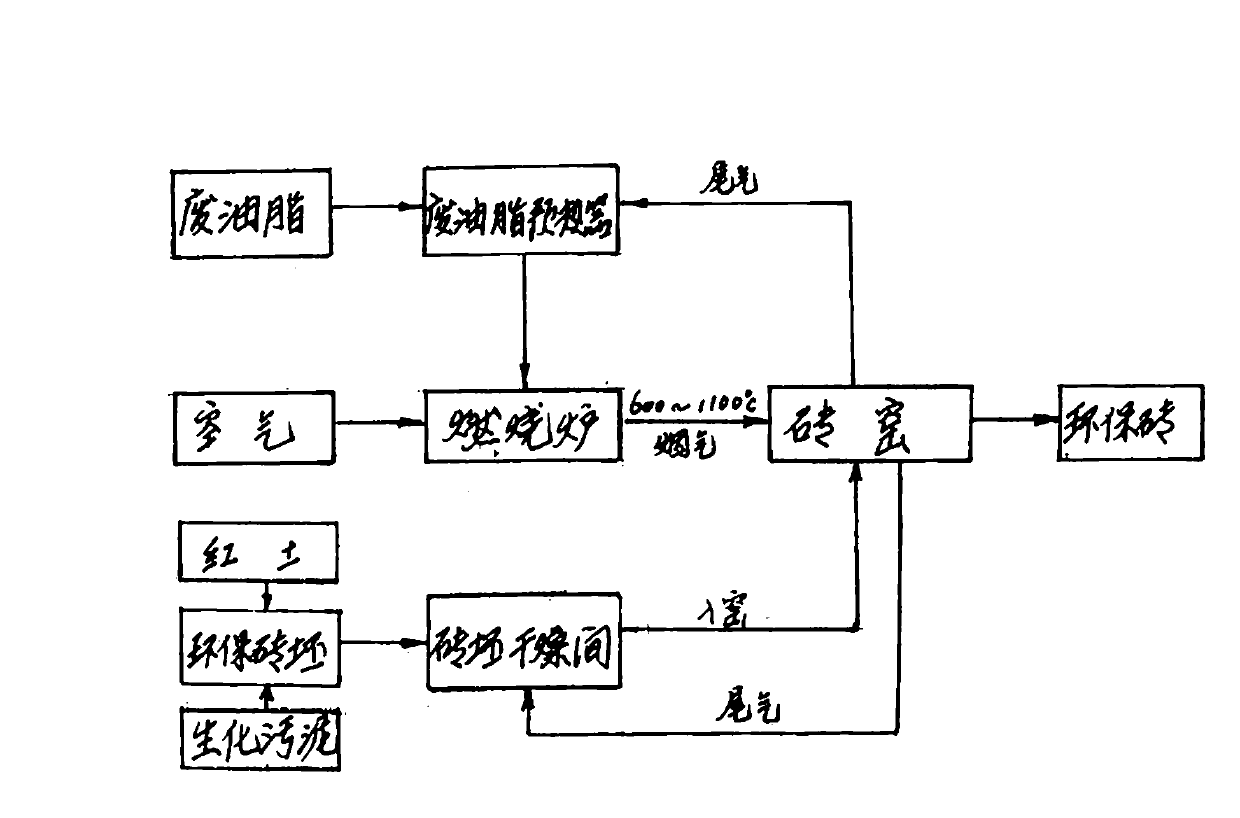

Method for preparing environment-friendly bricks by using mixture of biochemical sludge and red clay and by using waste oil as fuel

A biochemical sludge and environmentally friendly brick technology, applied in the production and application of clay products and ceramic materials, can solve problems such as harm to health, and achieve the effect of saving land, good strength and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of 1000kg material environmental protection brick

[0029] According to the proportion of the above-mentioned environmentally friendly bricks, weigh 300kg of biochemical sludge and 700kg of laterite, mix and stir the above-mentioned raw materials with appropriate amount of water, and make a plastic mixed mud, which is pressed in a brick press to form an environmentally friendly brick. The kiln is fired to obtain the finished environmental protection brick. The preparation of the environmental protection brick includes the following steps:

[0030] 1) Preparation of environmentally friendly brick mixture

[0031] According to the proportion of the above-mentioned environmentally friendly brick components, weigh the raw materials of each component, stir and mix them in the mixer, and prepare the environmentally friendly brick mixed mud with uniform particle size distribution and plasticity;

[0032] 2) Preparation of adobe

[0033] Push the mixed brick mud m...

Embodiment 2

[0038] Preparation of 1000kg material environmental protection brick

[0039] According to the above-mentioned ratio of environmentally friendly bricks, weigh 400kg of biochemical sludge and 600kg of laterite, mix and stir the above raw materials with appropriate amount of water, and make a plastic mixed mud, which is pressed in a brick press to obtain environmentally friendly bricks. After the bricks are dry, put them into Kiln firing makes the finished product of environmental protection brick, and the sintering temperature of environmental protection brick is 950 ℃, and its preparation process is with reference to embodiment 1.

Embodiment 3

[0041] Preparation of 1000kg material environmental protection brick

[0042] Weigh 500kg of biochemical sludge and 500kg of laterite according to the ratio (the moisture content of biochemical sludge is 30-80%), mix and stir the above raw materials with appropriate amount of water to make a plastic mixed sludge, which is produced in a brick press. The adobe is fired in a kiln after the adobe is dried. The sintering temperature of the environmental protection brick is 850°C, and then the environmental protection brick products are fired. Its preparation process refers to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com