Unacceptable product reprocessing technique in isobutylene production

A qualified product, isobutene technology, applied in the field of isobutene production of unqualified products, can solve the problems of isobutene product quality not meeting the requirements, affecting the economic cost of isobutene plant production, increasing the difficulty of MTBE production, etc., to avoid low-priced sales , Improve the qualified rate of the factory, and the practical effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

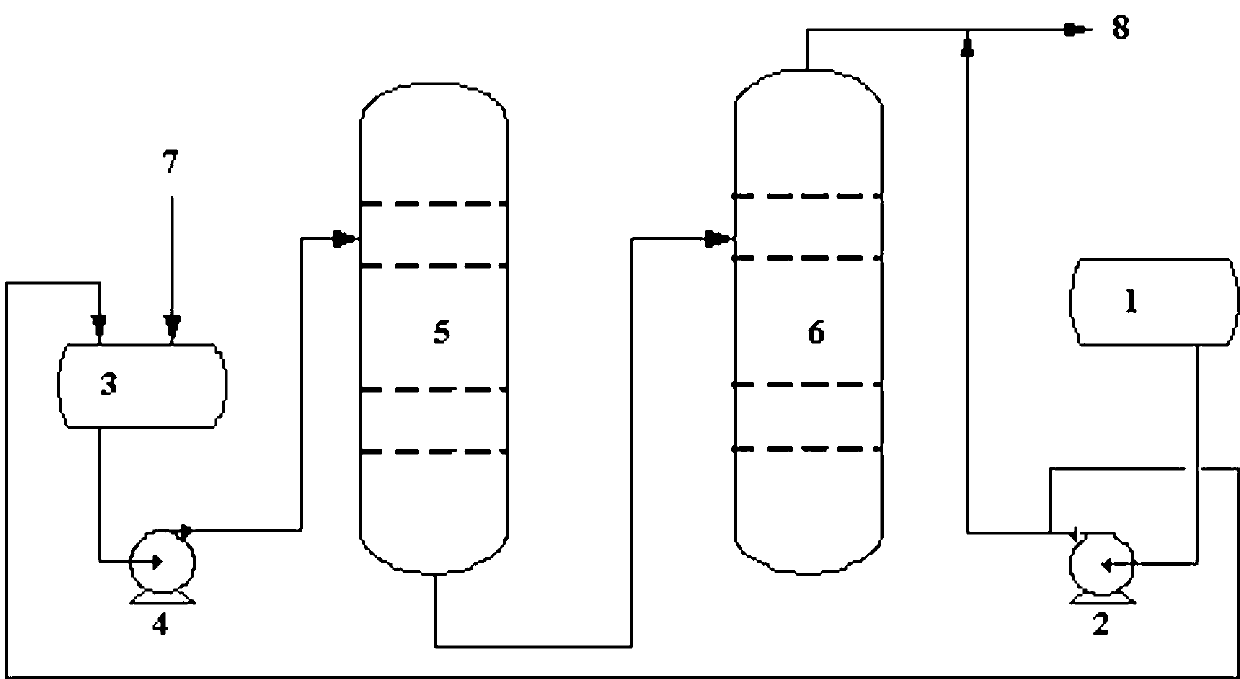

[0019] In the process of the present invention, the unqualified product tank 1 and the isobutylene intermediate storage tank 3 are connected by setting up an unqualified product delivery pipeline and an unqualified product pump 2 .

[0020] Wherein, the unqualified product tank 1 can be used as a spare qualified product tank under normal production conditions, and the unqualified product pump outlet is connected to the qualified product line to go to the qualified finished product tank area 8 .

[0021] The unqualified product is first stored in the unqualified tank 1, and sent to the isobutylene intermediate storage tank 3 through the unqualified product pump 2, mixed with the fresh product 7, and then enters the isobutylene light removal tower 5 through the isobutylene light removal tower feed pump 4, and the reflux is controlled The ratio is 2~4, the operating temperature of the tower is between 69~71°C, and the pressure at the top of the tower is 0.5~0.82 MPa. The materia...

Embodiment 2

[0023] Other conditions are the same as in Example 1, except that the reflux ratio of the light removal tower is controlled to be 2.5 to 3.5, the reflux ratio of the weight removal tower is 1.5 to 2.5, and the purity of the product at the outlet of the overhead distillation reaches more than 99.50 (wt)%.

Embodiment 3

[0025] Other conditions are the same as in Example 2, except that the refined raw materials are all unqualified products, which are not mixed with fresh products, and the purity of the outlet product of the overhead distillation reaches more than 99.20 (wt)%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com