Polyamide (PA) 6/ polyethylene terephthalate (PET) material for two-direction stretching composite film and production method thereof

A biaxial stretching and composite film technology, applied in the field of organic polymer materials, can solve the problems of high cost, lack of performance and quality stability, etc., and achieve the effect of fast crystallization speed and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

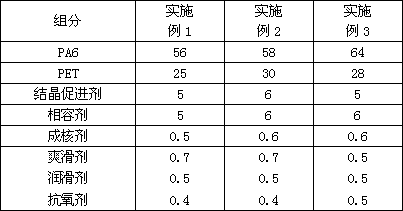

Examples

Embodiment Construction

[0010] Below in conjunction with embodiment the present invention will be further described:

[0011] Dry polycaprolactam (PA6) and polyethylene terephthalate (PET) at 120°C for 4 hours, and keep the water content below 0.03%; dry the crystallization accelerator at 80°C for 4 hours, and keep the water content below 0.03%. Below 0.02%. Pour the aforementioned dried polycaprolactam (PA6), polyethylene terephthalate (PET), and crystallization accelerator into a high-speed mixer, stir at a low speed, and add a compatibilizer, a nucleating agent, and a smoothing agent while stirring. Agents, lubricants and antioxidants; after stirring at low speed for 2 minutes, turn to high speed stirring, and stir for another 2 minutes after the internal temperature of the high speed mixer reaches 40°C. Finally, the stirred and mixed raw materials are added to a twin-screw extruder for blending and extrusion. The blending processing temperature is 240-260 ° C, the screw speed is 300 r / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com