High-solid anticorrosive paint and preparation method thereof

A technology of anti-corrosion coating and high solid content, applied in the field of coatings, can solve the problems of harming human health, polluting the environment, wasting valuable resources, etc., and achieving the effect of prolonging the life cycle, short time and obvious value-added effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

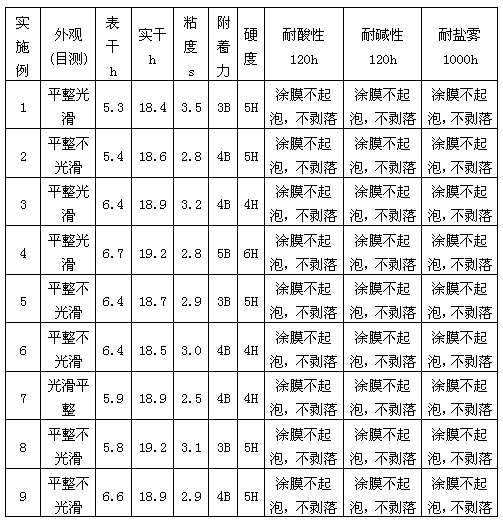

Examples

Embodiment 1

[0018] Embodiment 1: This high solid content adopts the raw material and preparation method of following weight.

[0019] Raw material weight: 35g of E51 epoxy resin, 16g of ethyl acetate, 40g of converter dust, 2.5g of talcum powder, 1.5g of coating additive and 5g of T-31 curing agent. Wherein, the converter dust is passed through a 200-mesh sieve, and the coating additive is 0.76g of polyamide wax, gas-phase SiO 2 A mixture of 0.31g and 0.43g of organic bentonite.

[0020] Preparation method: (1) Take the converter sludge, make it into a suspension, filter it with double-layer filter paper for many times, then put it in a blast drying oven at 106 degrees Celsius for 2 hours, take it out, put it in a mortar, and grind it with 200 mesh sieve to obtain converter dust;

[0021] (2) Mix converter dust and talcum powder evenly to obtain pigments and fillers;

[0022] (3) Mix the pigments and fillers with epoxy resin, ethyl acetate and coating additives and grind for 15 minute...

Embodiment 2

[0024] Embodiment 2: This high solid content anticorrosion coating adopts the following raw materials and preparation methods.

[0025] Raw material weight: 40g of E51 epoxy resin, 12g of ethyl acetate, 35g of converter dust, 3g of talcum powder, 2g of coating additive and 8g of T-31 curing agent. Wherein, the converter dust is passed through a 150-mesh sieve, and the coating additive is 1.01 g of polyamide wax, gas-phase SiO 2 A mixture of 0.4g and 0.59g of organic bentonite.

[0026] Preparation method: (1) Take the converter sludge, make it into a suspension, filter it with double-layer filter paper for many times, then put it in a blast drying oven at 100 degrees Celsius for 1 hour, take it out, grind it in a mortar, and grind it with 150 mesh sieve to obtain converter dust;

[0027] (2) Mix converter dust and talcum powder evenly to obtain pigments and fillers;

[0028] (3) Mix the pigments and fillers with epoxy resin, ethyl acetate and coating additives and grind fo...

Embodiment 3

[0030] Embodiment 3: This high solid content anticorrosion coating adopts the raw materials and preparation method of the following weight.

[0031] Raw material weight: E51 epoxy resin 44, ethyl acetate 17, converter dust 30, talcum powder 2.5, coating additive 1.5 and T-31 curing agent 5. Wherein, the converter dust passes through an 80-mesh sieve, and the coating additives are polyamide wax 0.77, gas phase SiO 2 A mixture of 0.3g and 0.43g of organic bentonite.

[0032] Preparation method: (1) Take the converter sludge, make it into a suspension, filter it with double-layer filter paper for many times, then put it in a blast drying oven at 150 degrees Celsius for 1.5 hours, take it out, grind it in a mortar, and grind it with 80 mesh sieve to obtain converter dust;

[0033] (2) Mix converter dust and talcum powder evenly to obtain pigments and fillers;

[0034] (3) Mix the pigments and fillers with epoxy resin, ethyl acetate and coating additives and stir for 5-10 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com