High-temperature sea water-base fracturing liquid suitable for formation temperature of 160 DEG C and preparation method thereof

A technology of high-temperature seawater and base pressure, applied in chemical instruments and methods, compounds of group 4/14 elements of the periodic table, and drilling compositions, can solve problems such as difficulty in meeting the requirements of fracturing construction, and achieve reduction Effects of injury, good tolerance, good complexation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

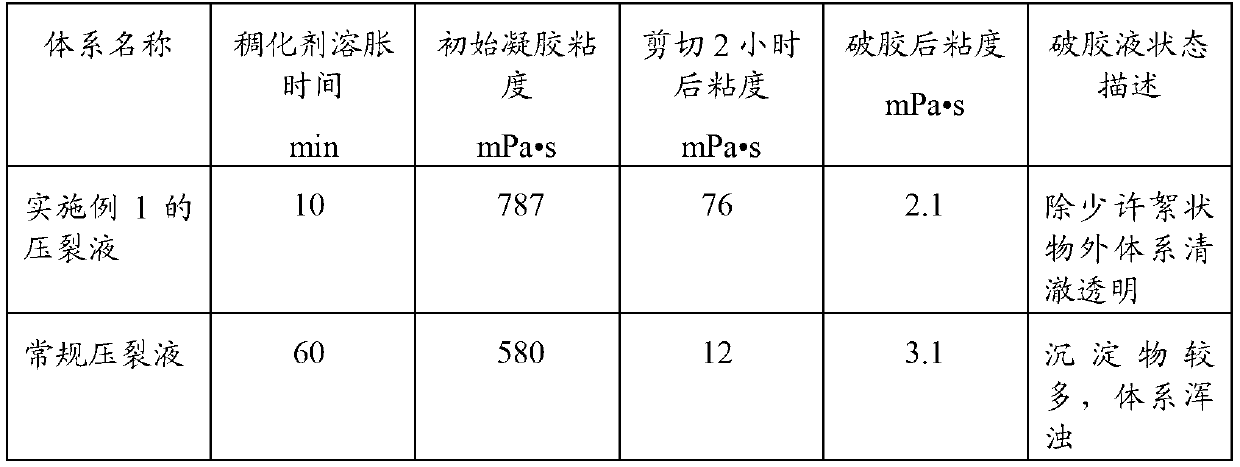

Embodiment 1

[0033] High temperature seawater based fracturing fluid

[0034] Raw materials (by weight):

[0035] 96 parts of sea water;

[0036] Thickener (hydroxyethyl carboxymethylsulfonate guar gum) 0.5 parts;

[0037] Chelating regulator (a mixed aqueous solution of ethylenediaminetetraacetic acid and hydroxyethylidene diphosphoric acid, wherein the weight percentage of ethylenediaminetetraacetic acid is 21%, the weight percent of hydroxyethylidene diphosphoric acid is 32%, and the balance is water, Both ethylenediaminetetraacetic acid and hydroxyethylidene diphosphate were purchased from Beijing Dewei Na Biotechnology Co., Ltd.) 1.5 parts;

[0038] Temperature stabilizer (mixed aqueous solution of hydroxylamine hydrochloride and sodium thiosulfate, wherein the weight percent of hydroxylamine hydrochloride is 12%, the weight percent of sodium thiosulfate is 21%, and the balance is water, hydroxylamine hydrochloride and sodium thiosulfate are purchased from Beijing Dewei Na Biotech...

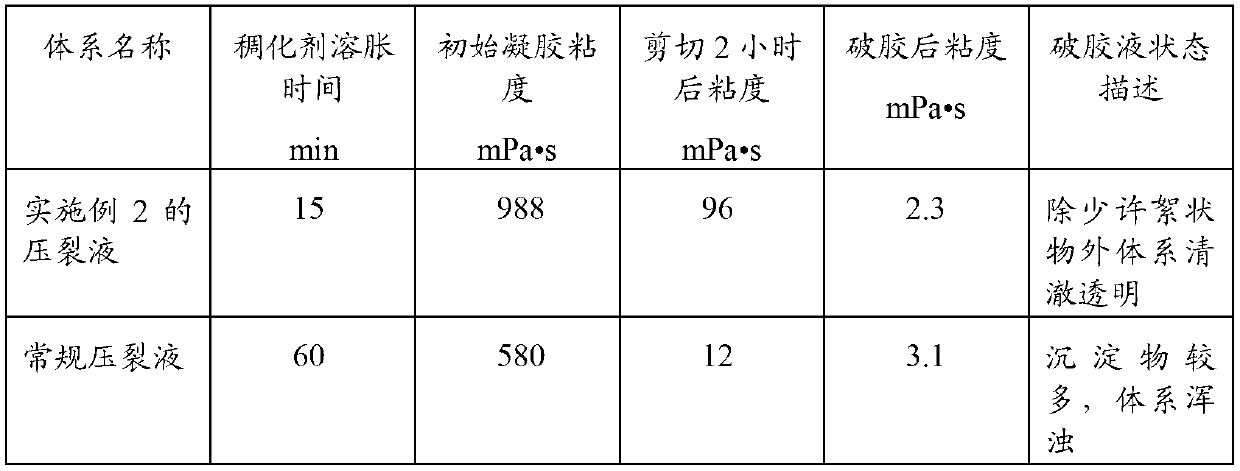

Embodiment 2

[0068] High temperature seawater based fracturing fluid

[0069] Raw materials (by weight):

[0070] Seawater 97.5 parts;

[0071] Thickener (hydroxyethylcarboxymethylsulfonate guar gum) 0.75 parts;

[0072] Chelation regulator (mixed aqueous solution of 2-phosphonic acid butane-1,2,4-tricarboxylic acid and triethylenetetramine hexaacetic acid hexasodium, in which 2-phosphonic acid butane-1,2,4-tricarboxylic acid 8% by weight of acid, 12% by weight of hexasodium triethylenetetraminehexaacetate, the balance is water, 2-phosphonobutane-1,2,4-tricarboxylic acid and triethylenetetramine Hexasodium hexaacetate was purchased from Beijing Dewei Na Biotechnology Co., Ltd.) 0.8 part;

[0073] Temperature stabilizer (mixed aqueous solution of hydrazine hydrate and sodium sulfite, wherein the weight percentage of hydrazine hydrate is 15%, the weight percentage of sodium sulfite is 5%, and the balance is water. Both hydrazine hydrate and sodium sulfite are purchased from Beijing Dewei ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com