Method for utilizing sludge containing vanadium and chromium

A technology of vanadium-chromium sludge and vanadium-chromium, which is applied in the field of utilization of vanadium-chromium-containing sludge, can solve the problems of high cost, poor treatment effect and high treatment cost, and achieve low cost, good treatment effect and low treatment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

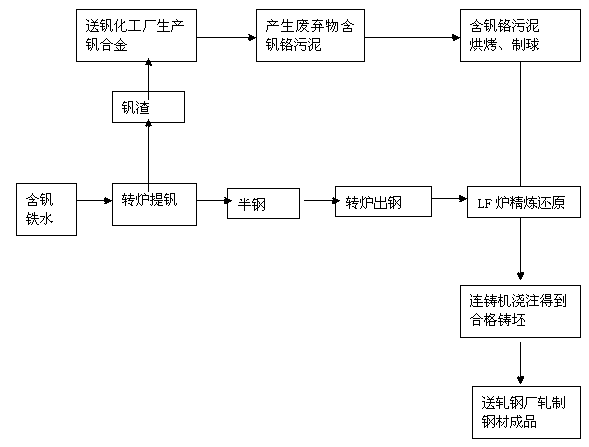

[0016] Embodiment 1: The utilization method of the vanadium-chromium-containing sludge adopts the following specific process steps.

[0017] The vanadium-chromium-containing sludge is first baked, and then the dried sludge is added with 1wt% phenolic resin organic binder and 8wt% silicon carbide powder, processed into balls and baked again to obtain a compressive strength ≥ 600N / ball vanadium-chromium-containing mud balls, the main components of vanadium-chromium-containing mud balls are: CaO: 3%, Cr 2 o 3 : 10%, V 2 o 5 : 25%, SiO 2 <13%, P<0.030%, S<0.60%, moisture<0.5%. After the vanadium-chromium-containing mud balls are prepared, return the vanadium-chromium-containing mud balls to the refining process of the steelmaking LF furnace for utilization: when the vanadium-chromium-containing mud balls are added to the microalloying of vanadium and chromium in the LF furnace, the timing of adding them is selected in the LF furnace slag Add after the color turns yellow, and ...

Embodiment 2

[0018] Embodiment 2: The utilization method of this vanadium-chromium-containing sludge adopts the following specific process steps.

[0019] The vanadium-chromium-containing sludge is first baked, and then the baked sludge is added with 5wt% phenolic resin organic binder and 5wt% silicon carbide powder, processed into balls and baked again to obtain a compressive strength ≥ 600N / ball vanadium-chromium-containing mud balls, the main components of vanadium-chromium-containing mud balls are: CaO: 10%, Cr 2 o 3 : 15%, V 2 o 5 : 15%, SiO 2 <13%, P<0.030%, S<0.60%, moisture<0.5%. After the vanadium-chromium-containing mud balls are prepared, return the vanadium-chromium-containing mud balls to the refining process of the steelmaking LF furnace for utilization: when the vanadium-chromium-containing mud balls are added to the microalloying of vanadium and chromium in the LF furnace, the timing of adding them is selected in the LF furnace slag Add after the color becomes yellowis...

Embodiment 3

[0020] Embodiment 3: The utilization method of the vanadium-chromium-containing sludge adopts the following specific process steps.

[0021] The vanadium-chromium-containing sludge is first baked, and then the baked sludge is added with 3wt% phenolic resin organic binder and 2wt% silicon carbide powder, processed into spherical objects and baked again to obtain a compressive strength ≥ 600N / ball vanadium-chromium-containing mud balls, the composition weight percentage of vanadium-chromium-containing mud balls is: CaO: 8%, Cr 2 o 3 : 12%, V 2 o 5 : 18%, SiO 2<13%, P<0.030%, S<0.60%, moisture<0.5%. After the vanadium-chromium-containing mud balls are prepared, return the vanadium-chromium-containing mud balls to the refining process of the steelmaking LF furnace for utilization: when the vanadium-chromium-containing mud balls are added to the microalloying of vanadium and chromium in the LF furnace, the timing of adding them is selected in the LF furnace slag Add after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com