Method for treating normal pressure leaching of transitional nickel laterite ore

A nickel laterite and transitional technology, which is applied in the field of atmospheric pressure leaching of transitional nickel laterite and nickel laterite processing, can solve the problems of low nickel leaching rate, difficult liquid-solid separation, and failure to meet discharge standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

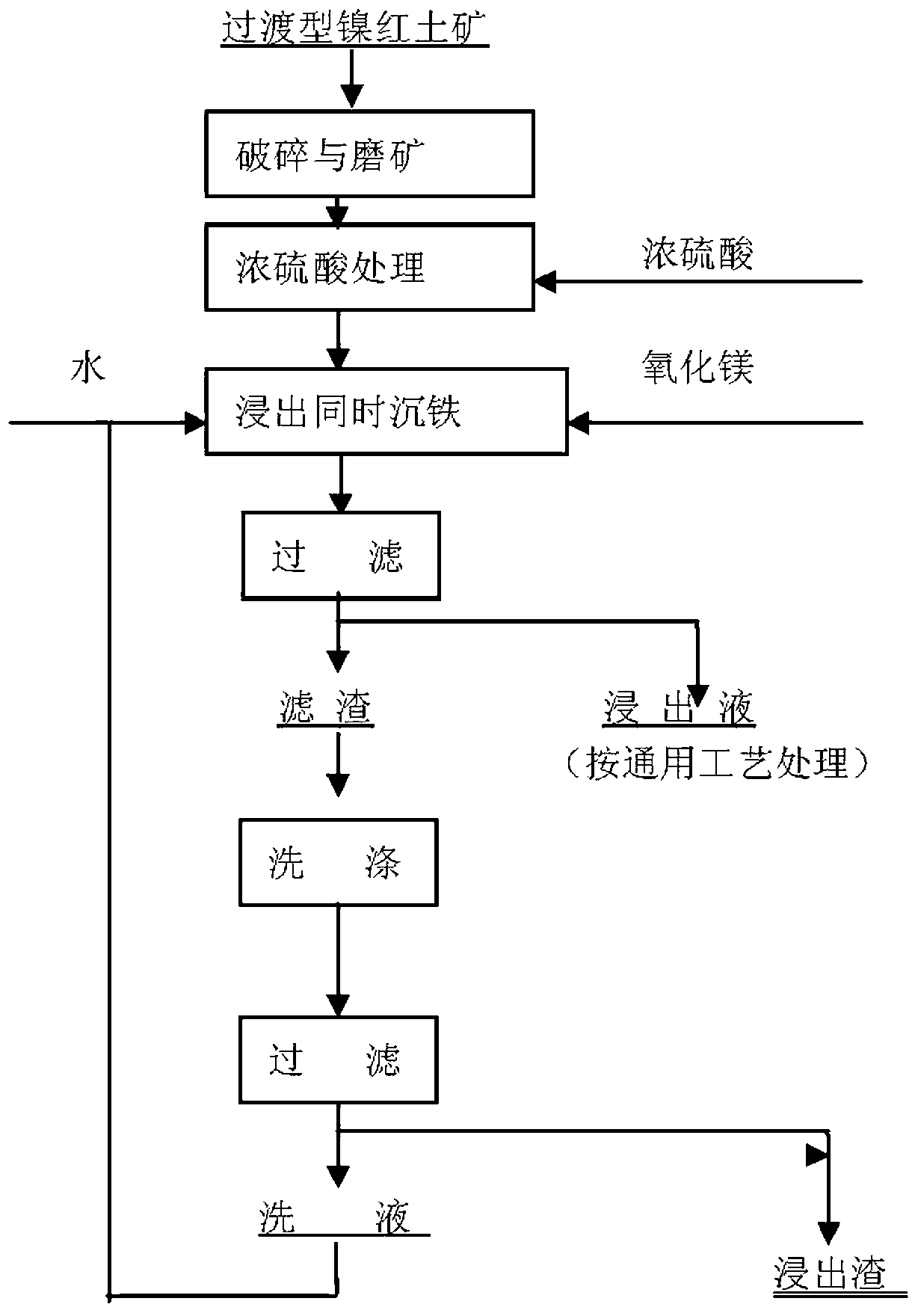

Method used

Image

Examples

Embodiment 1

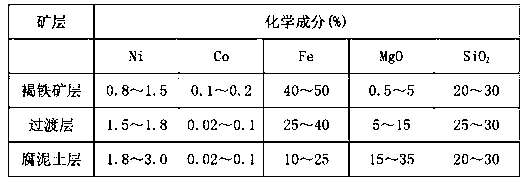

[0016] The chemical composition of the transitional nickel laterite used is .

[0017] chemical composition Ni co Fe 2 o 3 SiO 2 MgO CaO Al 2 o 3 Content (mass%) 1.51 0.09 54.5 25.60 10.51 1.65 2.85

[0018] The transitional nickel laterite ore with this composition has a particle size of -200 mesh, accounting for 80%, water content of 30%, adding 75% concentrated sulfuric acid, a liquid-solid ratio of 4:1, a temperature of 95°C, and a pH of 3.0. leaching and removing iron for 2.5 hours at the same time. After leaching, liquid-solid separation was performed, and the leaching residue was washed at 90°C with a liquid-solid ratio of 2:1. The volume of the leaching liquid and the washing liquid were measured separately and the nickel content was assayed. Heavy, test the nickel content. The test results show that the leaching rate of nickel is 89.44%, and the leaching rate of cobalt is 72.43%.

Embodiment 2

[0020] The chemical composition of the transitional nickel laterite used is .

[0021] chemical composition Ni co Fe 2 o 3 SiO 2 CaO Al 2 o 3 MgO Content (mass%) 1.46 0.078 53.87 24.60 2.65 3.85 12.51

[0022] The treatment process is the same as in Example 1, and the technical conditions are: laterite ore particle size -200 mesh accounts for 85%, material moisture content is 35%, particle size is -200 mesh and accounts for 85%, adding 80% concentrated sulfuric acid, the liquid-solid ratio is 4: 1. Under the conditions of temperature 95°C and pH control of 3.5, leaching simultaneously removes iron for 2.5 hours. After leaching, liquid-solid separation is performed, and the leaching residue is washed at 90°C with a liquid-solid ratio of 2:1. The leaching solution and lotion were measured in volume and tested for nickel content, and the leaching residue was weighed after drying to test for nickel content. The test results show that...

Embodiment 3

[0024] The chemical composition of the transitional nickel laterite used is .

[0025] chemical composition Ni co Fe 2 o 3 SiO 2 CaO Al 2 o 3 MgO Content (mass%) 1.57 0.078 52.87 23.60 1.65 3.85 12.41

[0026] The treatment process is the same as in Example 1, and the technical conditions are: laterite ore particle size -200 mesh accounts for 85%, the material contains 40% water, the particle size is -200 mesh and accounts for 80%, and the concentrated sulfuric acid with a feed rate of 80% is added, and the liquid-solid ratio is 4: 1. Under the conditions of temperature 95°C and pH control of 3.0, leaching simultaneously removes iron for 2.5 hours. After leaching, liquid-solid separation is performed, and the leaching residue is washed at 80°C with a liquid-solid ratio of 2:1. The leachate and washing liquid are measured separately The nickel content was tested by volume, and the leaching slag was dried and weighed to test the nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com