Bio-electrochemical system used for copper sulfide ore leaching

A bioelectrochemical, copper sulfide technology, applied in the field of bioelectrochemical systems, can solve the problems of serious pollution, high cost, slow reaction speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0017] Implementation Mode 1: Device Installation

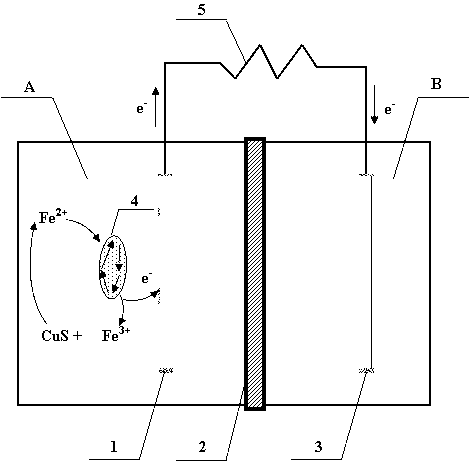

[0018] according to figure 1 The principle diagram shown in the installation device: the cation exchange membrane (2) divides the device into an anode chamber (A) and a cathode chamber (B). The transmittance of the cation exchange membrane (2) used is 96%, and the membrane thickness is 0.3mm. Bursting strength ≥ 0.5MPa. The volume of the anode chamber (A) and the cathode chamber (B) are both 25cm 3 . A carbon felt with a thickness of 0.5 cm was placed as an electrode in both the anode chamber (A) and the cathode chamber (B), with an area of 2.5×2.5 cm. The anode (1) and the cathode (3) are connected by titanium wire, wire and external resistance (5) of 500Ω.

Embodiment approach 2

[0019] Implementation Mode 2: Device Operation

[0020] After the installation of the device is completed, the enriched and cultured bacterial solution is centrifuged and the supernatant is discarded, the bacterial sediment is mixed with the newly prepared bacterial culture solution, and then added to the anode chamber (A), and finally copper sulfide is added; the solution of the cathode chamber (B) is 50mM potassium ferricyanide and 50mM K 2 HPO 4 . In the anode compartment (A), Fe 2+ exist Acidithiobacillus ferrooxidans (4) is oxidized to Fe under the action of 3+ , copper sulfide and Fe 3+ A chemical reaction occurs to obtain Cu 2+ , Fe 2+ and elemental S. The sealed anode chamber (A) maintains an anaerobic environment, and the elemental S cannot be further oxidized, so that the elemental sulfur can be recovered, and the generation of harmful sulfur oxidation products (such as sulfate) can also be avoided. Fe 2+ Oxidized to Fe 3+ The generated electrons are tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com