Novel carburizing-constant temperature-quenching process for heavy-duty gears

A new process, isothermal technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of gear surface oxidation, difficult operation of the furnace, high energy consumption, reduce oxidative decarburization, avoid frequent high-low temperature cycle times, The effect of shortening the process flow

Inactive Publication Date: 2013-06-05

上海市机械制造工艺研究所有限公司

View PDF1 Cites 11 Cited by

- Summary

- Abstract

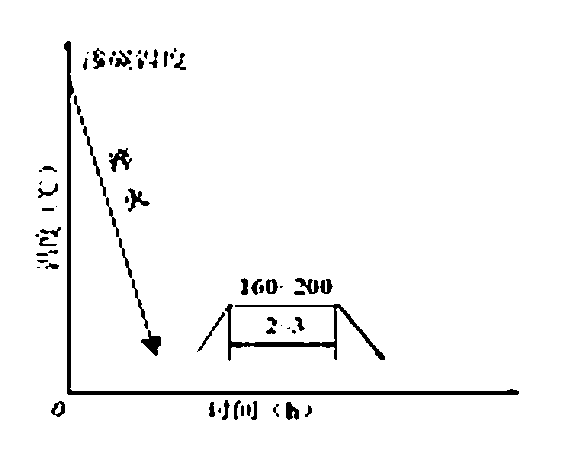

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This process has the disadvantages of long process, high energy consumption, oxidation and decarburization of the gear surface, large distortion, difficult operation of heavy-duty gears in hot state, high labor intensity, and low productivity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 17

[0045] The following examples take 17Cr2Ni2Mo steel as an example,

Embodiment 1

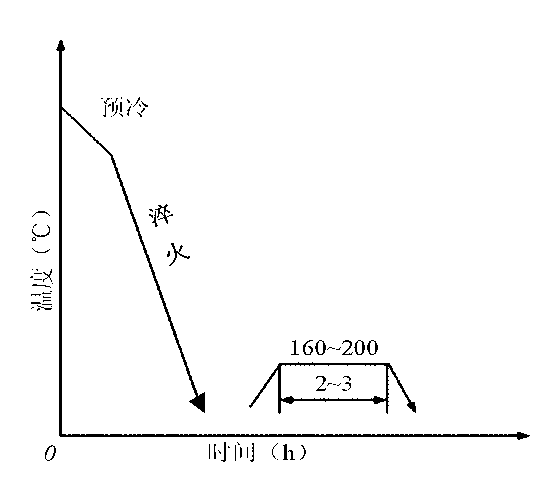

[0046] Example 1: Carburizing at 930°C (10h) - cooling in the furnace to 600°C tempering (2h) - 820°C (2h) oil quenching - tempering at 200°C (4h) - air cooling.

Embodiment 2

[0047] Example 2: Carburizing at 930°C (10h) - cooling in furnace to 630°C tempering (2h) - 820°C (2h) oil quenching - tempering at 200°C (4h) - air cooling.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel carburizing-constant temperature-quenching process for heavy-duty gears. The process comprises the steps of: (a) after carburizing treatment, cooling down to a temperature range (600-650 DEG C) below Ar1, and carrying out constant temperature for a period of time until the temperature of workpieces is equalized; (b) heating up to quenching temperature, and quenching after carrying out heat insulation for a period of time according to the requirements of the process; and (c) carrying out low-temperature tempering. According to the process, after the carburizing stage for the gears is completed, the gears are cooled down to some temperature below the Ar1 through furnace cooling, and the constant-temperature retention is carried out, so that the first-time phase conversion is realized; the gears are directly heated up to the quenching temperature after the temperature of the gears is equalized at the temperature, so that the second-time phase conversion is realized; and the quenching treatment is carried out, so that the third-time phase conversion is realized. Proved by production practices, the process disclosed by the invention has the advantages that the energy source consumption is remarkably reduced, the oxidation and decarburization of the gears are reduced, the distortion amount is reduced, the heat treatment process flow is shortened, and the efficiency of labor productivity is increased.

Description

technical field [0001] The invention relates to a metal heat treatment process, in particular to a gear heat treatment process. Background technique [0002] Gear is a widely used mechanical transmission part. In mechanical equipment, gear plays an important role in transmitting power, changing speed and direction of rotation. Generally, gears are divided into three categories according to their transmission forms: cylindrical gears are used for transmission between parallel two shafts; bevel gears are used for transmission between intersecting two shafts; worm gears and worms are used for transmission between crossing two shafts. Compared with belt drive, which relies on friction to transmit power, and chain drive, which transmits motion through the meshing of chain and sprocket teeth, gear drive has the advantages of simple structure, relatively fixed transmission ratio, precise transmission ratio, and large transmission load. [0003] Hard tooth surface gears are mainly ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F17/00C21D9/32C21D1/18

Inventor 陈德华任颂赞叶俭李光瑾

Owner 上海市机械制造工艺研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com