Material heat conduction analysis device based on fluorescence method

An analysis device and fluorescence method technology, applied in the field of thermal property analysis of materials, can solve problems such as being susceptible to electromagnetic interference and unable to be widely used in industrial measurement fields, and achieve good anti-electromagnetic interference ability, good measurement accuracy, and simple measurement principle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

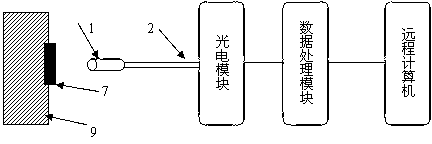

[0044] An embodiment of the application of the fluorescence method material heat conduction analysis device of the present invention to the measurement of gas thermal diffusivity, refer to Figure 4 , 5 , which works as follows:

[0045] First, the probe 1 is placed in the gas atmosphere 10 to be measured. After the power is turned on, the light source 4 starts to work, and the light source 4 emits excitation light to be transmitted along the optical fiber 2, and then focused to the fluorescent sensing material 9 through the optical lens 8; The sensing material emits corresponding fluorescence after being excited, and the fluorescence is coupled into the photoelectric module through the optical lens along the optical fiber 2, and then the optical detector 5 demodulates the optical signal into an electrical signal. Then the electrical signal enters the signal conditioning and data processing circuit, and the corresponding temperature value is obtained after processing.

[004...

Embodiment 2

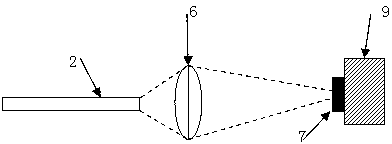

[0051] An embodiment of the fluorescence method substance heat conduction analysis device of the present invention can be applied to measure the thermal diffusivity of solid materials, refer to figure 2 , 4 , 6 and 8, the principle of the measurement is: firstly, the measured solid material is pressed Image 6 As shown fixed, the fluorescent sensing material 7 is closely attached to the surface of the solid material 11 to be measured, and then the light source 4 emits a strong laser to heat the area where the fluorescent sensing material 7 is located; after the fluorescent sensing material 7 is heated, the fluorescent sensing The temperature of the part where the material 7 is located rises, and the temperature change process of the fluorescent sensing material 7 can be recorded after the temperature measurement process starts, and the thermal diffusivity of the measured solid material 9 can be obtained after processing and analysis; then only need to know the measured The h...

Embodiment 3

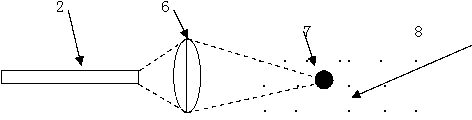

[0053] The present invention can be applied to a kind of embodiment of measuring the thermal diffusivity of liquid sample, refer to figure 2 , 4 , 7 and 8, the principle of its work is: first place the fluorescent sensing material 7 in the liquid sample 10 to be measured, so that the light energy passing through the optical lens 6 is converged on the fluorescent sensing material 7; the purpose of using the optical lens 6 The purpose is to quickly heat the fluorescent sensing material, and at the same time increase the intensity of the fluorescent light entering the optical fiber and improve the signal-to-noise ratio.

[0054] When the light source drive circuit adjusts the light source to output high-energy laser to heat the fluorescent sensing material 7, the system enters the temperature measurement process: the light source 4 continuously sends excitation pulses, and the fluorescent sensing material 7 emits fluorescence after being excited, and the fluorescent light ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com