Electrode for zinc bromine storage battery and zinc bromine storage battery assembled by the same

A zinc-bromine storage battery and electrode technology, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of not considering hydrogen evolution inhibition in batteries, complex system design, low energy efficiency, etc., and achieve inhibition of bromine permeation and hydrogen Effects of precipitation, high energy density, and reduction of reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

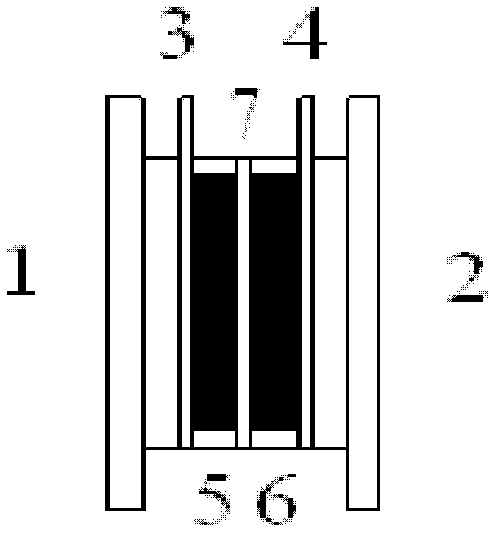

Method used

Image

Examples

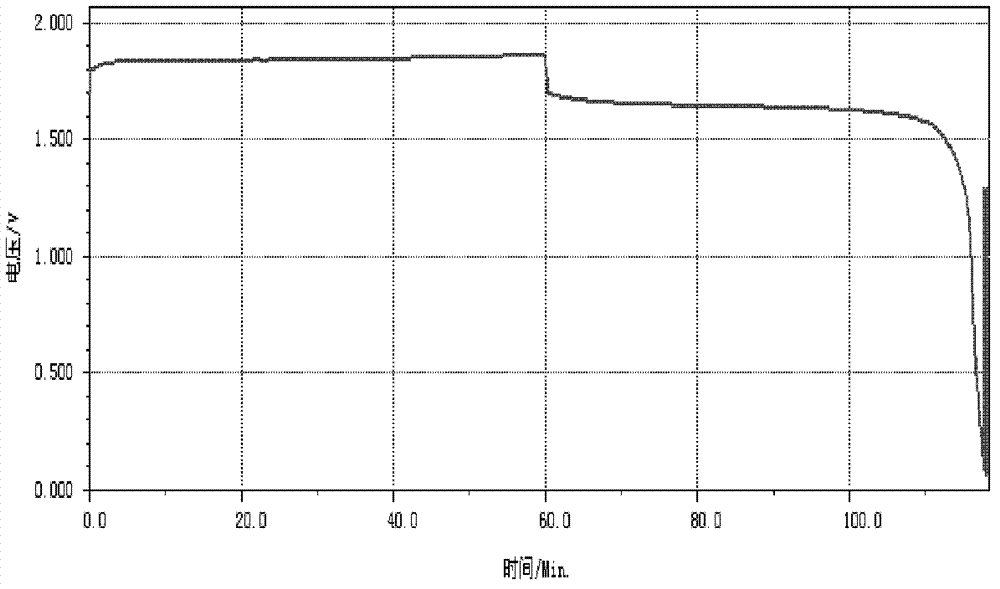

Embodiment 1

[0034] Preparation of positive electrode paste:

[0035] 1) Electrode paste slurry configuration: by weight, mechanically mix 5 parts of carbon powder, 2 parts of trimethylammonium bromide, 40 parts of zinc bromide, 1 part of PTFE, and 3 parts of distilled water into a paste for later use;

[0036] 2) Use the method of screen printing to evenly coat the electrode paste slurry on one side of the foamed titanium, with a loading capacity of 10mg / cm 2 ;

[0037] 3) Place the side coated with pole paste up and let it stand for 2 hours;

[0038] 4) Zinc bromide solution configuration: Prepare a 4mol / L zinc bromide solution, soak the prepared positive electrode in the solution for 10 minutes, assemble the battery, and assemble the side coated with the electrode paste facing the separator.

[0039] Preparation of negative electrode paste:

[0040] 1) Electrode paste configuration: by weight, mechanically mix 10 parts of carbon powder, 1 part of zinc powder, 50 parts of zinc bromide...

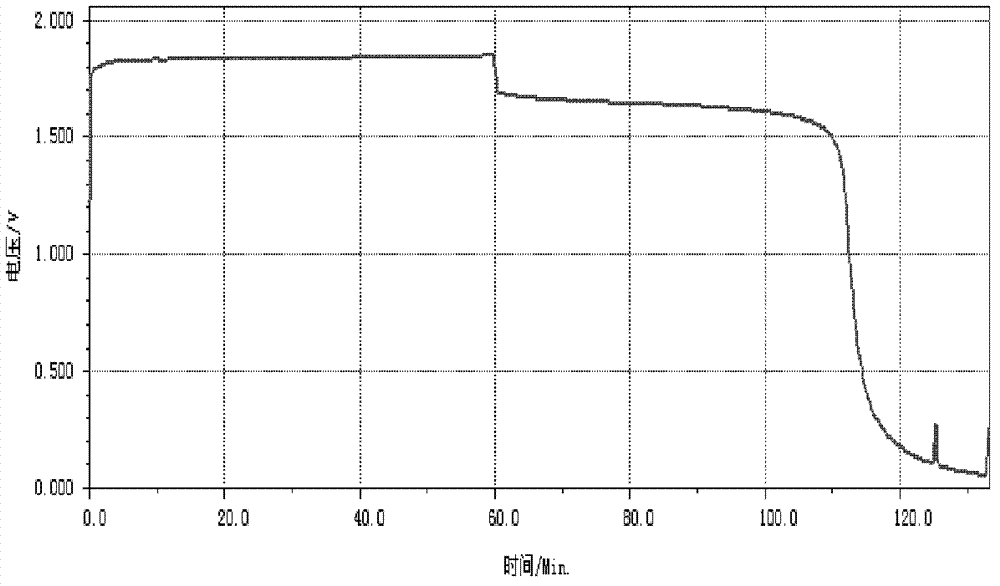

Embodiment 2

[0046] Preparation of positive electrode paste:

[0047] 1) Pole paste slurry configuration: by weight, 1 part of carbon powder, 1 part of trimethylammonium bromide, 10 parts of zinc bromide, 1 part of PTFE, and 3 parts of distilled water are mechanically mixed and stirred into a paste for later use;

[0048] 2) Use the method of scraping to evenly coat the electrode paste slurry on one side of the carbon felt; load: 5mg / cm 2 .

[0049] 3) Vacuum (0.1kpa) suction filtration for 10min on the side not coated with electrode paste;

[0050] 4) Zinc bromide solution configuration: Prepare a 4mol / L zinc bromide solution, soak the prepared positive electrode in the solution for 10 minutes, assemble the battery, and assemble the side coated with the electrode paste facing the separator.

[0051] Preparation of negative electrode paste:

[0052] 1) Electrode paste configuration: by weight, 1 part of carbon powder, 1 part of zinc powder, 10 parts of zinc bromide, 1 part of PVDF, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com