A method for extracting d-ribose from fermentation broth by ultrafiltration and ion exchange technology

An ion exchange and cation exchange technology is applied in the field of extracting D-ribose from fermentation broth by using ultrafiltration and ion exchange technology, which can solve the problems of easy blockage of step membrane flux and short process route, and achieve simplified multi-stage membrane separation. The effect of high process and extraction separation, simple and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

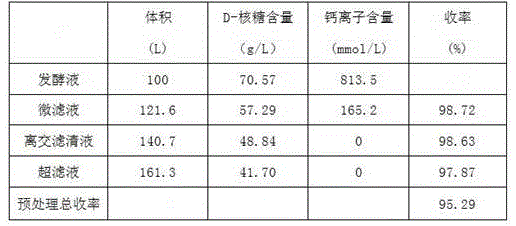

Embodiment 1

[0021] 100L of D-ribose fermentation broth passes through a microfiltration membrane with a membrane pore size of 1000nm, the membrane entry pressure is 0.2MPa, the membrane exit pressure is 0.1MPa, and the operating temperature is 25°C. After the fermentation broth is concentrated by 10 times, 20L of dialysis water is added. The filtrate passes through the 732-type cation exchange resin column at a flow rate of 2BV / H, and the effluent from the positive column is also directly connected to the 717-type anion-exchange resin column at a flow rate of 2BV / H. The ion exchange liquid passes through the ultrafiltration membrane with a molecular weight cut-off of 5000, the operating pressure is 1.4MPa, and the operating temperature is 30-35°C. After the ion exchange liquid is concentrated 15 times, 25L of dialysis water is added. The filtrate passes through 732-type cation exchange resin, 331-type anion-exchange resin, and HZ-803 resin in sequence. The resin chromatography effluent is...

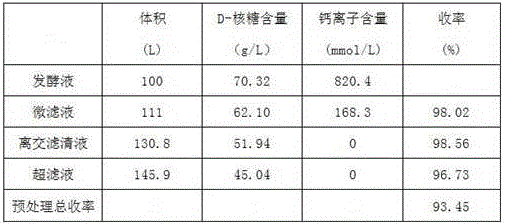

Embodiment 2

[0024] 100L of D-ribose fermentation broth passed through a microfiltration membrane with a membrane pore size of 200nm, the membrane entry pressure was 0.2MPa, the membrane exit pressure was 0.1MPa, and the operating temperature was 25°C. After the fermentation broth was concentrated 10 times, 30L of dialysis water was added. The filtrate passes through the 732-type cation exchange resin column at a flow rate of 2BV / H, and the effluent from the positive column is also directly connected to the 717-type anion-exchange resin column at a flow rate of 2BV / H. The ionotropic solution passes through the ultrafiltration membrane with a molecular weight cut-off of 1000, the operating pressure is 1.4MPa, and the operating temperature is 30-35°C. After the ionotropic fluid is concentrated 15 times, 30L of dialysis water is added. According to the subsequent extraction method in Example 1, after the D-ribose crystals were vacuum-dried, a total of 4.93 Kg of D-ribose product was obtained. ...

Embodiment 3

[0027] 100L of D-ribose fermentation broth passes through a microfiltration membrane with a membrane pore size of 500nm, the membrane entry pressure is 0.2MPa, the membrane exit pressure is 0.1MPa, and the operating temperature is 25°C. After the fermentation broth is concentrated 8 times, 25L of dialysis water is added. The filtrate passes through the 732-type cation exchange resin column at a flow rate of 2BV / H, and the effluent from the positive column is also directly connected to the 717-type anion-exchange resin column at a flow rate of 2BV / H. The ionotropic solution passes through the ultrafiltration membrane with a molecular weight cut-off of 2000, the operating pressure is 1.4MPa, and the operating temperature is 30-35°C. After the ionotropic fluid is concentrated 15 times, 25L of dialysis water is added. The ultrafiltrate passes through 732-type cation exchange resin, 331-type anion-exchange resin, and HZ-803 resin in sequence. The resin chromatography effluent is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com