High-solid-content polyamine-adduct-modified epoxy resin coating combination for ballast tank

A technology of epoxy resin and composition, applied in the direction of epoxy resin coating, coating, etc., can solve the problems of inconvenient operation, high VOC content, construction and environmental hazards, etc., and achieve the effect of long service life and convenient cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

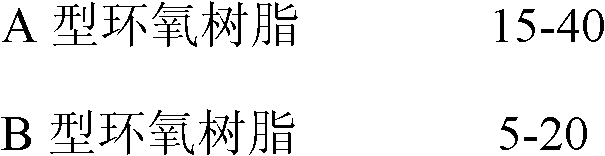

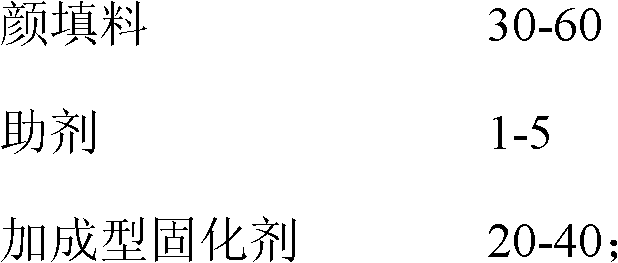

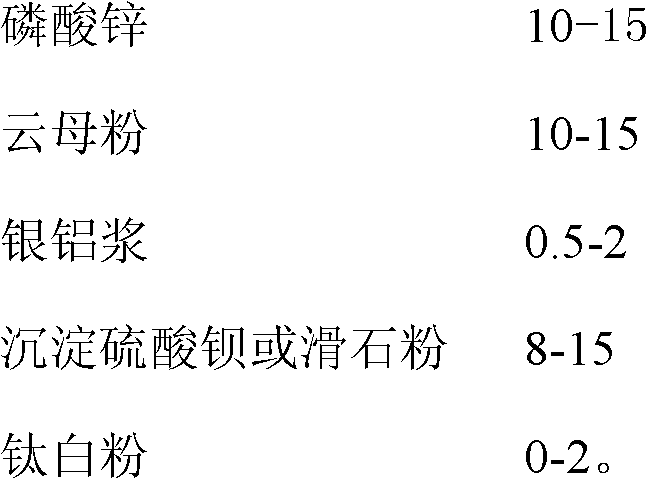

[0035] The formula of component A (parts by weight) is as follows:

[0036]

[0037] Component B: BECKOPOX VEH2106 model product produced by Cytec.

[0038] Preparation of component A: bisphenol A epoxy resin, bisphenol F epoxy resin, diluent, wetting and dispersing agent, defoamer, leveling agent, zinc phosphate, titanium dioxide, barium sulfate, anti-settling Add the agent to a 100-liter stainless mixing tank, stir and mix evenly at high speed, then grind to a fineness within 40um with a three-roller, disperse at high speed for 30 minutes, then add mica powder and silver-aluminum paste, disperse evenly, and pack out Get A component.

[0039] The B component can be divided directly.

[0040] How to use: Mix component A and component B according to a weight ratio of 5:2, stir well, and mature for about 15 minutes. If the viscosity is too high, it can be diluted with a small amount of distilled water, and the amount added should not exceed the total amount. 5%, using high-pressure ai...

Embodiment 2

[0042] The formula of component A (parts by weight) is as follows:

[0043]

[0044] Component B: BECKOPOX VEH2177 model product produced by Cytec.

[0045] Preparation of component A: bisphenol A epoxy resin, bisphenol F epoxy resin, diluent, wetting and dispersing agent, defoamer, leveling agent, zinc phosphate, titanium dioxide, talcum powder, anti-settling Add the agent to a 100-liter stainless mixing tank, stir and mix evenly at high speed, then grind to a fineness within 40um with a three-roller, disperse at high speed for 30 minutes, then add mica powder and silver-aluminum paste, disperse evenly, and pack out Get A component.

[0046] The B component can be divided directly.

[0047] How to use: Mix A component and B component according to the weight ratio of 5:1, stir well, and mature for about 15 minutes. If the viscosity is too high, it can be diluted with a small amount of distilled water, and the amount added should not exceed the total amount. 5%, using high-pressure a...

Embodiment 3

[0049] The formula of component A (parts by weight) is as follows:

[0050]

[0051] Component B: BECKOPOX VEH2189 model product produced by Cytec.

[0052] Preparation of component A: bisphenol A epoxy resin, bisphenol F epoxy resin, diluent, wetting and dispersing agent, defoamer, leveling agent, zinc phosphate, titanium dioxide, barium sulfate, anti-settling Add the agent to a 100-liter stainless mixing tank, stir and mix evenly at high speed, then grind to a fineness within 40um with a three-roller, disperse at high speed for 30 minutes, then add mica powder and silver-aluminum paste, disperse evenly, and pack out Get A component.

[0053] The B component can be divided directly.

[0054] How to use: Mix A component and B component according to the weight ratio of 5:1, stir well, and mature for about 15 minutes. If the viscosity is too high, it can be diluted with a small amount of distilled water, and the amount added should not exceed the total amount. 5%, using high-pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com