Full oil base drilling fluid with high dynamic shear force ratio

An all-oil-based drilling fluid technology, applied in the field of oil drilling, can solve the problems of low mechanical penetration rate, increased drilling cycle and production cost, dynamic shear force and plastic viscosity increase, etc., to improve overall performance, save production cost, The effect of improving rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] Prepare full oil-based drilling fluid according to the following proportions and the above-mentioned preparation method:

[0051] Diesel: 100L; cetyl stearate: 2.0Kg; N-hexadecanoic acid amide: 1.0Kg; polyoxyethylene lauryl ether: 1.0Kg; ethylenediamine octadecanoic acid amide polymer: 1.0Kg; Rubber: 0.5Kg; Calcium Oxide: 2.0Kg; Organic Soil: 3.0Kg; Organic Lignite: 2.0Kg.

example 2

[0053] Prepare full oil base drilling fluid according to the following ratio:

[0054] White oil: 100L; octadecyl stearate: 2.0Kg; stearyl amide: 1.0Kg; lauryl polyoxyethylene ether: 1.0Kg; ethylenediamine stearylamide polymer: 1.0Kg; polystyrene Calcium Oxide: 2.0Kg; Organic Soil: 3.0Kg; Organic Lignite: 2.0Kg; Barite: 55Kg.

example 3

[0056] Prepare full oil base drilling fluid according to the following ratio:

[0057] Gas oil: 100Kg; cetyl stearate: 2.0Kg; octadecanoic acid amide: 1.0Kg; lauryl alcohol polyoxyethylene ether: 1.0Kg; ethylenediamine octadecanoic acid amide polymer: 1.0Kg; polyethylene Toluene: 0.3Kg; Calcium Oxide: 2.0Kg; Organic Soil: 3.0Kg; Organic Lignite: 2.0Kg; Barite: 160Kg.

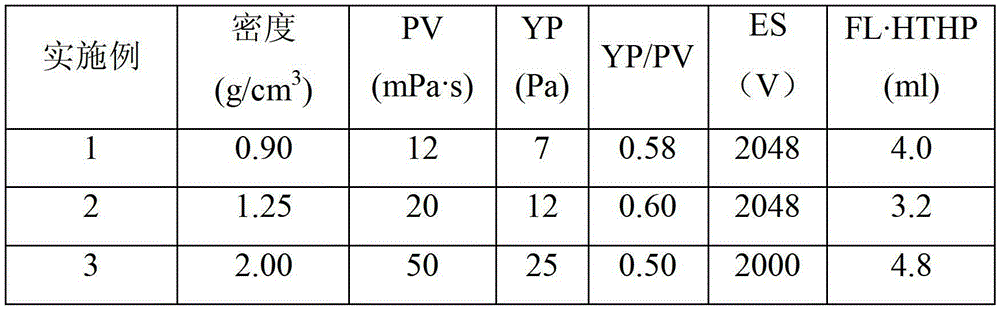

[0058] The performance parameters of the full oil-based drilling fluid prepared in the above three examples are shown in Table 1

[0059] Table 1

[0060]

[0061] in:

[0062] PV: Plastic viscosity; YP: Dynamic shear force; YP / PV: Dynamic plastic ratio; ES: Demulsification voltage; FL·HTHP: High temperature and high pressure filtration loss.

[0063] The above results show that the all-oil-based drilling fluid system of the present invention has high dynamic shear force, low plastic viscosity and high dynamic-plastic ratio, and the drilling fluid has strong suspending ability and thixotropy, and can effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com