Water-based viscosity-increasing and shearing agent for drilling fluid and preparation method thereof

A water-based, drilling fluid technology, applied in the field of drilling fluid water-based viscosity-increasing and shearing agent and its preparation, can solve the problems of insufficient temperature resistance stability, insufficient dynamic-plastic ratio, and narrow application range, etc., to achieve excellent growth The effect of sticking and cutting performance and temperature resistance, excellent compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

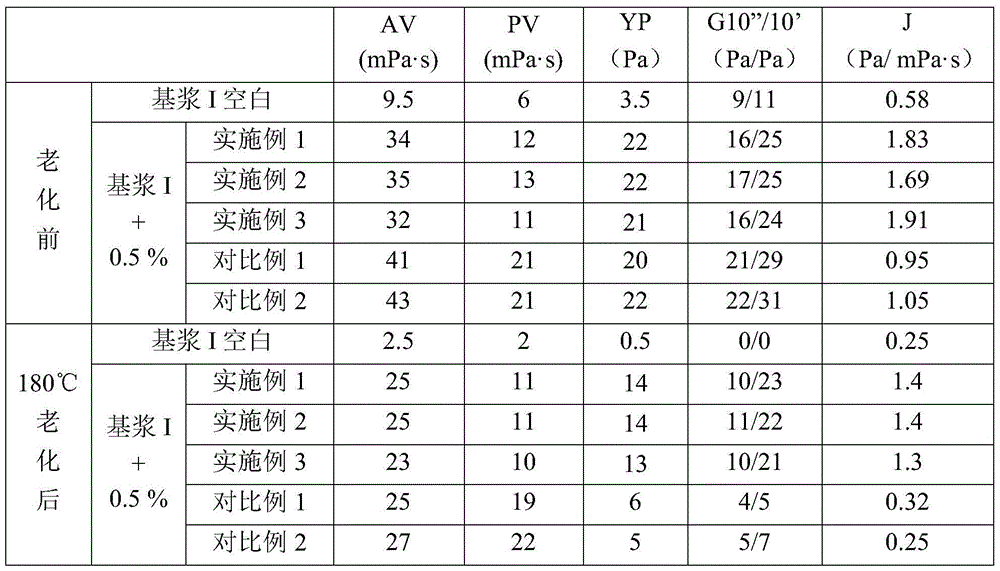

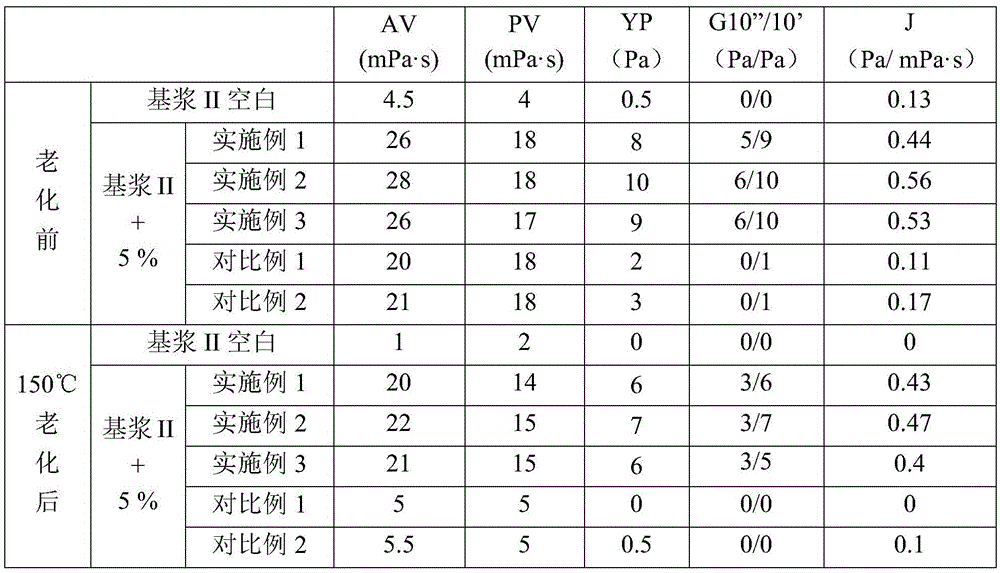

Examples

preparation example Construction

[0017] The invention provides a preparation method of a water-based viscosity-increasing and shearing agent for drilling fluid, the method comprising the following steps:

[0018] (1) Dissolve and mix the anionic monomer, nonionic monomer and cationic monomer in water under stirring;

[0019] (2) Adjust the pH value of the mixed solution obtained in step (1) to 5-10, and continue stirring;

[0020] (3) Add oxidizing agent, reducing agent and azo initiator to the mixture obtained in step (2), and react under stirring.

[0021] In step (1), the inventors of the present invention found that by blending anionic monomers, nonionic monomers and cationic monomers in a certain ratio, the viscosity-increasing performance, temperature resistance performance and system applicability can be obtained better product. The inventors of the present invention have found through a large number of tests that the amount ratio of the anionic monomer, the nonionic monomer and the cationic monomer ...

Embodiment 1

[0035] (1) Mix water, benzenesulfonic acid, acrylamide, and dimethylaminoethyl methacrylate at a mass ratio of 7000:600:500:200 at room temperature, and stir for 25 minutes at a stirring speed of 400 r / min;

[0036] (2) Adjust the pH value of the solution obtained in step (1) to 8, and continue stirring for 40 minutes at a stirring speed of 350 r / min under a water bath condition of 35° C.; then

[0037] (3) Add ammonium persulfate, sodium bisulfite and azobisisobutyronitrile successively in a mass ratio of 2:4:2, and stir and react with a stirring speed of 300r / min for 4 hours, wherein the weight of the azo initiator is 0.5% by weight of the solid raw material gross weight in the step (1);

[0038] (4) Dry the mixture obtained in step (3) at 90° C. for 12 hours, and then grind it into a powder with an average particle size of about 60 mesh, which is the final product.

Embodiment 2

[0040] (1) Mix water, acrylic acid, acrylamide, and dimethyl diallyl ammonium chloride at normal temperature in a mass ratio of 7000:550:550:250, and stir for 20 minutes at a stirring speed of 350 r / min;

[0041] (2) Adjust the pH value of the solution obtained in step (1) to 7, and continue stirring for 30 minutes at a stirring speed of 300 r / min under a water bath condition of 30 ° C; then

[0042] (3) Potassium persulfate, sodium bisulfite and azobisisoheptanonitrile were added successively in a mass ratio of 1:3:1, and stirred and reacted for 3 hours with a stirring speed of 250r / min, wherein the weight of the azo initiator was 0.2% by weight of the solid raw material gross weight in the step (1);

[0043] (4) Dry the mixture obtained in step (3) at 85° C. for 16 hours, and then grind it into a powder with an average particle size of about 80 mesh, which is the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com