Preparation method of high-temperature-resistant high-dispersity bentonite

A technology of high dispersibility and bentonite, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor dispersibility and poor high temperature resistance of bentonite, and achieve improved basic performance, excellent dispersibility, and good portability The effect of cuttings capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

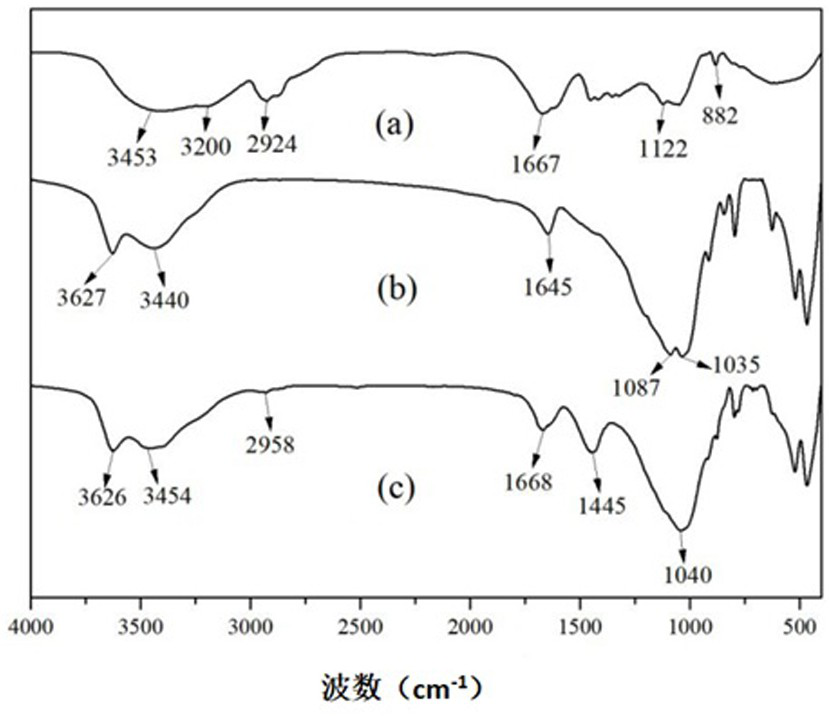

Image

Examples

Embodiment 1

[0021] The preparation method of this high-temperature-resistant high-dispersibility bentonite:

[0022] Weigh 2g of hydroxyethyl cellulose and 7g of acrylamide and disperse them in 50mL of deionized water, set the stirring speed at 70r / min and the stirring time for 5min, fully stir on a magnetic stirrer, and add 44% sodium hydroxide dropwise Solution, adjust the pH value to 7; pour the stirred solution into a three-neck flask, then add 0.045g ammonium persulfate and 0.045g sodium bisulfate, set the microwave synthesis reaction, the temperature of the reaction station is 50°C, and the reaction time is The reaction time was 50min and the microwave power was 200W. The reaction was synthesized in a microwave synthesis reaction station, and nitrogen gas was introduced. During the synthesis process, magnetic stirring was maintained to obtain a transparent colloidal liquid. After standing at room temperature, the reactant was precipitated with ethanol and washed several times. ; The...

Embodiment 2

[0024] The preparation method of this high-temperature-resistant high-dispersibility bentonite:

[0025] Weigh 1g of hydroxyethyl cellulose and 4g of acrylamide and disperse them in 55mL of deionized water, set the stirring speed at 65r / min, and stir for 4min, stir fully on a magnetic stirrer, and add 44% sodium hydroxide dropwise Solution, adjust the pH value to 7; pour the stirred solution into a three-necked flask, then add 0.025g ammonium persulfate and 0.025g sodium bisulfate, set the microwave synthesis reaction, the temperature of the reaction station is 40°C, and the reaction time is The reaction time was 35min and the microwave power was 220W. The reaction was synthesized in the microwave synthesis reaction station, and nitrogen gas was introduced. During the synthesis process, magnetic stirring was maintained to obtain a transparent colloidal liquid. After standing at room temperature, the reactant was precipitated with ethanol and washed several times. ; The precipi...

Embodiment 3

[0027] The preparation method of this high-temperature-resistant high-dispersibility bentonite:

[0028] Weigh 1g of hydroxyethyl cellulose and 5g of acrylamide and disperse them in 60mL of deionized water, set the stirring speed at 60r / min and the stirring time for 5min, fully stir on a magnetic stirrer, and add 44% sodium hydroxide dropwise Solution, adjust the pH value to 7; pour the stirred solution into a three-neck flask, then add 0.03g ammonium persulfate and 0.03g sodium bisulfate, set the microwave synthesis reaction, the temperature of the reaction station is 45 ° C, the reaction time The reaction time was 45min, and the microwave power was 250W. The reaction was synthesized in a microwave synthesis reaction station, and nitrogen gas was introduced. During the synthesis process, magnetic stirring was maintained to obtain a transparent colloidal liquid. After standing at room temperature, the reactant was precipitated with ethanol and washed several times. ; The preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com