Three-stage genetic transcription control method for improving cellulosic ethanol yield and genetic engineering bacterial strain

A cellulosic ethanol and gene transcription technology, applied in the field of genetic engineering strains, three-stage gene transcription regulation to improve cellulosic ethanol production, and can solve problems affecting ethanol production and yield, low consumption rate, low conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Construction of mixed sugar co-fermentation strain

[0045] The starting strain WT comes from the industrial strain of Saccharomyces cerevisiae produced by Angel Yeast Company. After splitting the spores from industrial diploids and transforming them into haploids, the dominant strains with better fermentation characteristics were screened through fermentation, and they were used as the original industrial starting strains for our experiment.

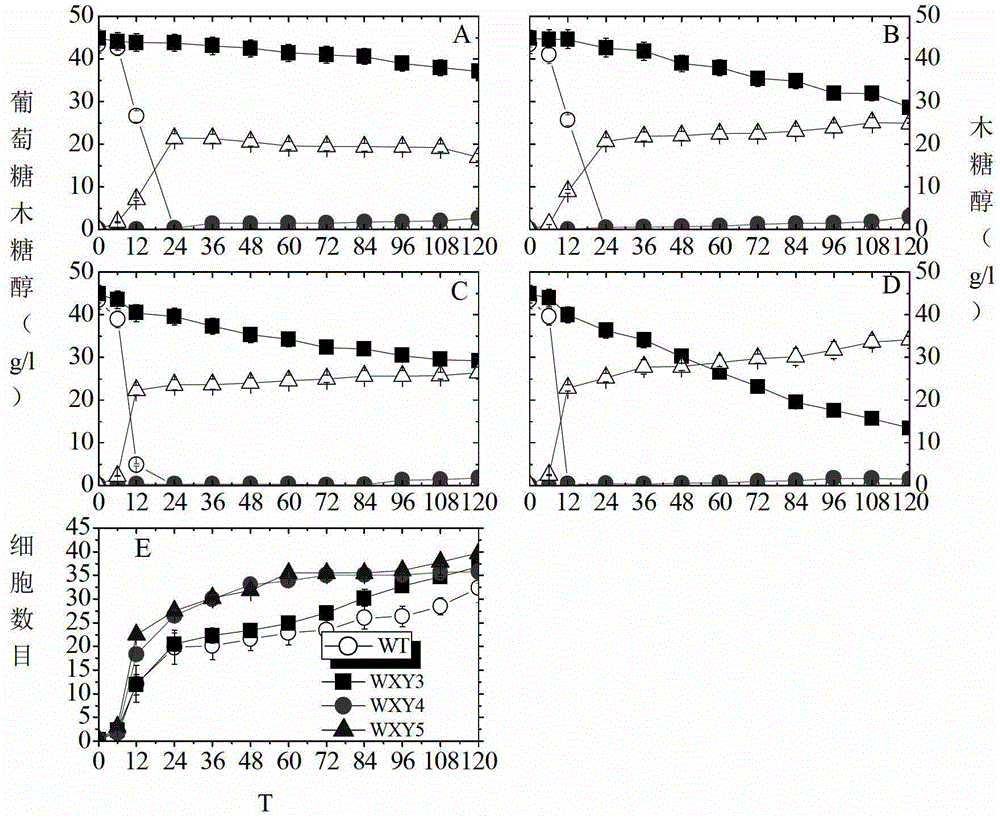

[0046] The plasmid p61 was transformed into WT to obtain WXY1, and its strain contained two genes pADH1-RPE1 and pPGK1-XDH; the plasmid p62 was transformed into WXY1 to obtain WXY2, and the strain additionally contained pADH1-XR4m and pPGK1-XK; WXY2, to get WXY3, this strain additionally contains multiple copies of pPGK1-RKI1 and pADH1-TAL1, and this strain can initially utilize xylose to produce ethanol; transform the plasmid pUC-3XK270R into WT, and get WXY4, this strain contains three genes pADH1- XR(K270R) / pPGK1-XDH / pPGK1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com