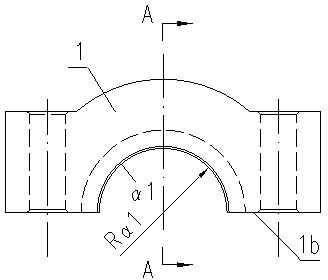

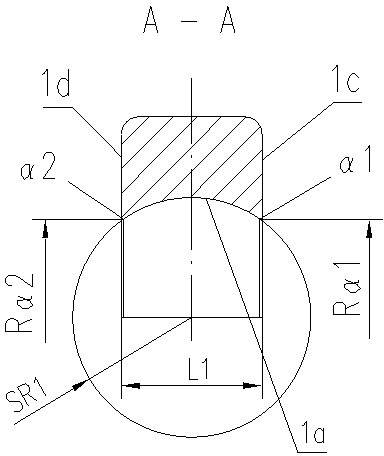

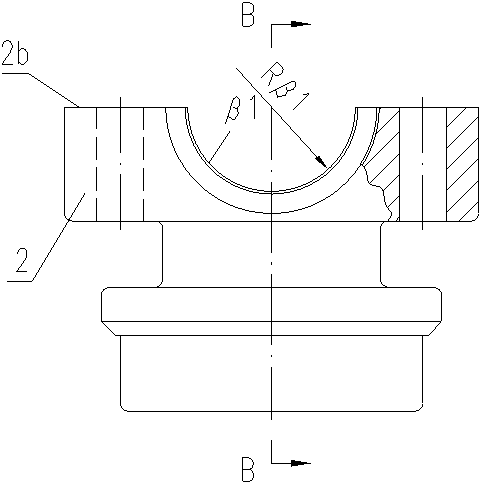

An induction hardening device for the concave spherical surface of the connecting seat of the blade

A technology of induction hardening and quenching device, which is applied in the direction of quenching device, improvement of process efficiency, furnace type, etc., can solve problems such as difficult control of induction distance, melting of concave spherical surface in operation, scrapping of blade connection seat, etc., to avoid sharp corners Effect problem, solution to low-speed rotation problem, effect of hardened layer depth control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0102] Depend on Figure 9 Known, an induction hardening device for the concave spherical surface of the shovel connecting seat, including: a semicircular step shielding ring 4, a full circle step shielding ring 5, a rotary assembly 6, a rotary drive assembly 7, a cabinet assembly 8 and an electric control Cabinet 9; wherein, the upper end of the rotary drive assembly 7 is fixedly connected to the rotary assembly 6, and the lower end is fixedly connected to the inside of the cabinet assembly 8; the upper end of the rotary assembly 6 is placed with a full-circle stepped shielding ring 5; in addition, the electric control cabinet 9 There are man-machine interface 9a, programmable controller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com