Smelting method for treating zinc leached residues in mixed manner by using oxygen leached residues

A technology of zinc leaching slag and mixed treatment, which is applied in the field of zinc smelting, can solve the problems of high production cost, flue gas treatment, high energy consumption, etc., and achieve the effects of saving fuel, reducing energy consumption, and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples, and the percentages mentioned in the present invention are all mass percentages.

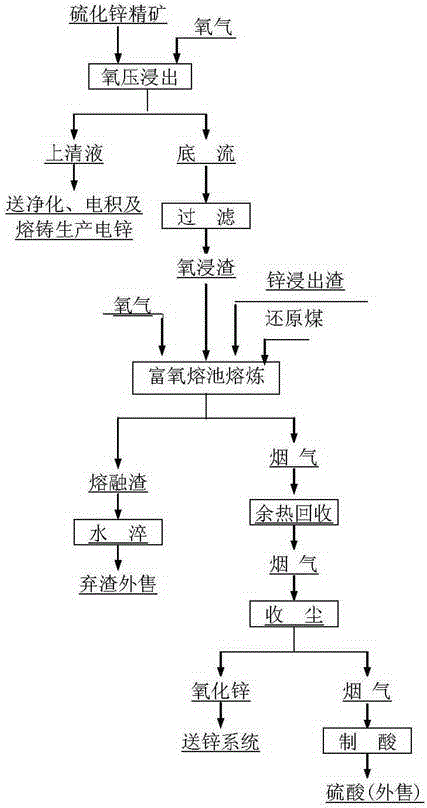

[0030] Such as figure 1 Shown, a kind of smelting method of zinc leaching slag mixed treatment with oxygen leaching slag, concrete steps are:

[0031] (1) After direct leaching of zinc sulfide concentrate at 110°C-150°C (atmospheric pressure or pressurized), an underflow is produced, the temperature of the underflow is 80°C-85°C, the solid concentration of the underflow is 30%-35%, and the acidity is 20 g / L~60g / L, directly filtered without flotation, to obtain an oxygen leaching residue with high sulfur content and low zinc content, and the supernatant is sent to purification, electrowinning and casting to produce electrolytic zinc. The oxygen leaching residue contains 48-52% of S, 16-20% of Fe and 1-3% of Zn.

[0032] (2) Add zinc leaching slag to the oxygen leaching slag so that the sulfur content ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com