Heat treatment technology for enhancing foam magnesium alloy

A technology for foaming magnesium alloys and enhancing foams, which is applied in the field of alloy manufacturing, can solve the problems of poor corrosion resistance of foamed magnesium alloys, and achieve the effects of overcoming poor corrosion resistance, simple and fast process, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first step, insulation treatment

[0027] With a box-type resistance furnace, the 30×30×30mm 3 The closed-cell AZ31 foamed magnesium alloy with a uniform porosity of 60% is subjected to heat preservation treatment at 480°C for 20 hours;

[0028] In the above treatment process, the AZ31 foamed magnesium alloy used is carried out under the condition that the volume ratio is ordinary casting silica sand: graphite powder = 1:2 mixture for protection, and the matrix material of the foamed magnesium alloy is completely covered with the mixture, and the covering layer The thickness is 6 cm above the highest point of the base material of the foamed magnesium alloy.

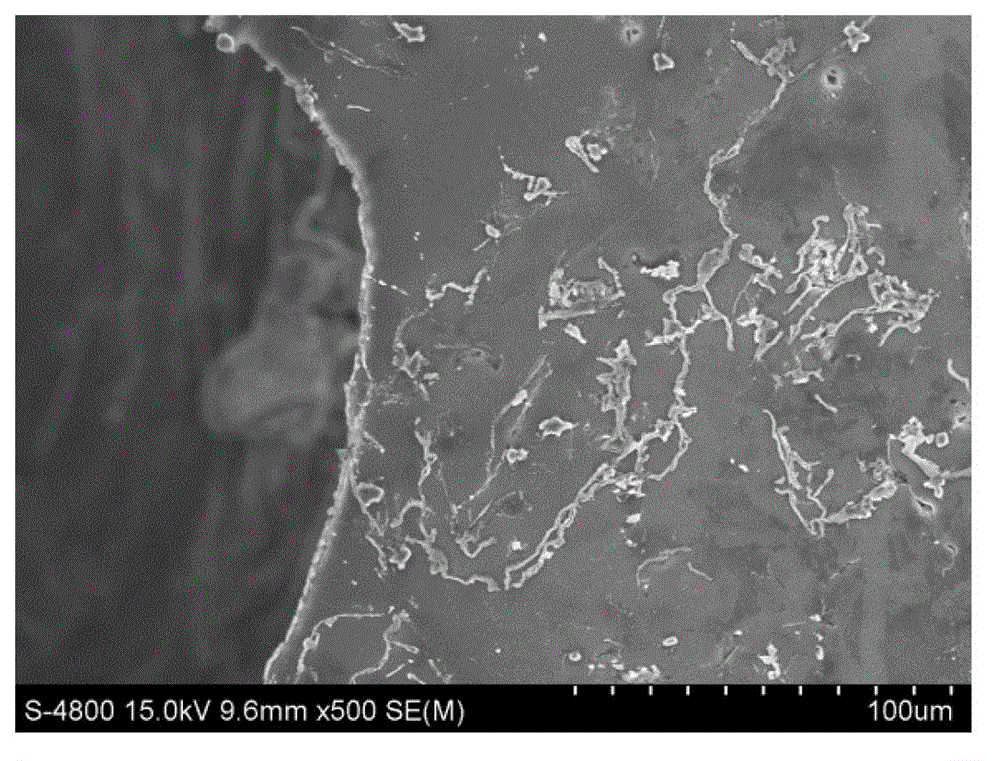

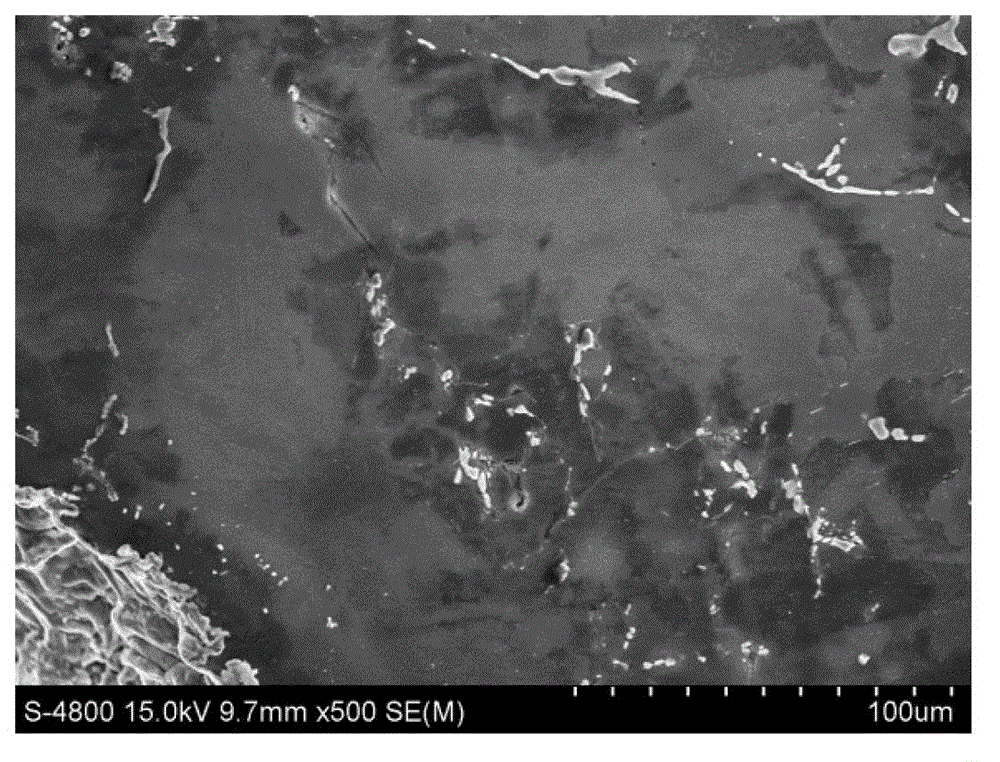

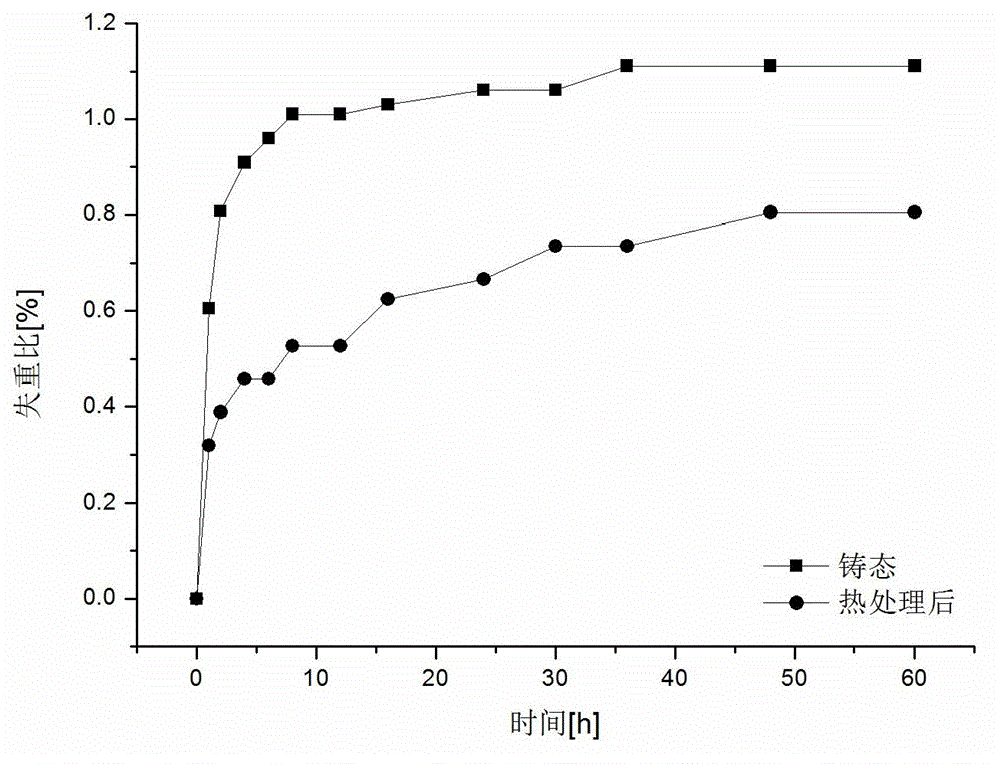

[0029] figure 1 It shows that the as-cast microstructure morphology of the AZ31 foamed magnesium alloy in this embodiment before heat preservation treatment is that a large amount of aggregated elements appear at the grain boundary, and more massive precipitates also appear inside the grain; figure 2 It sh...

Embodiment 2

[0037] In addition to the heat preservation process of the first step, the used AZ31 foamed magnesium alloy adopts a volume ratio of silica sand for ordinary casting: graphite powder=1:1 The mixture is protected under the condition that the matrix material of the foamed magnesium alloy is made of this mixture Complete coverage, the thickness of the covering layer is 5 cm higher than the highest point of the base material of the foamed magnesium alloy, and the others are the same as in Example 1.

Embodiment 3

[0039] In addition to the heat preservation treatment process of the first step, the used AZ31 foamed magnesium alloy adopts a volume ratio of silica sand for ordinary casting: graphite powder=1:6 The mixture is carried out under the protection condition, and the base material of the foamed magnesium alloy is made of the mixture Complete coverage, the thickness of the covering layer is 5.5 cm higher than the highest point of the base material of the foamed magnesium alloy, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com