Preparation method and growth equipment of magnesium fluoride crystal

A technology of crystal growth and magnesium fluoride, which is applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems that crystals cannot meet the requirements of use, and achieve excellent crystal optical quality, eliminate fatal effects, and high transmittance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

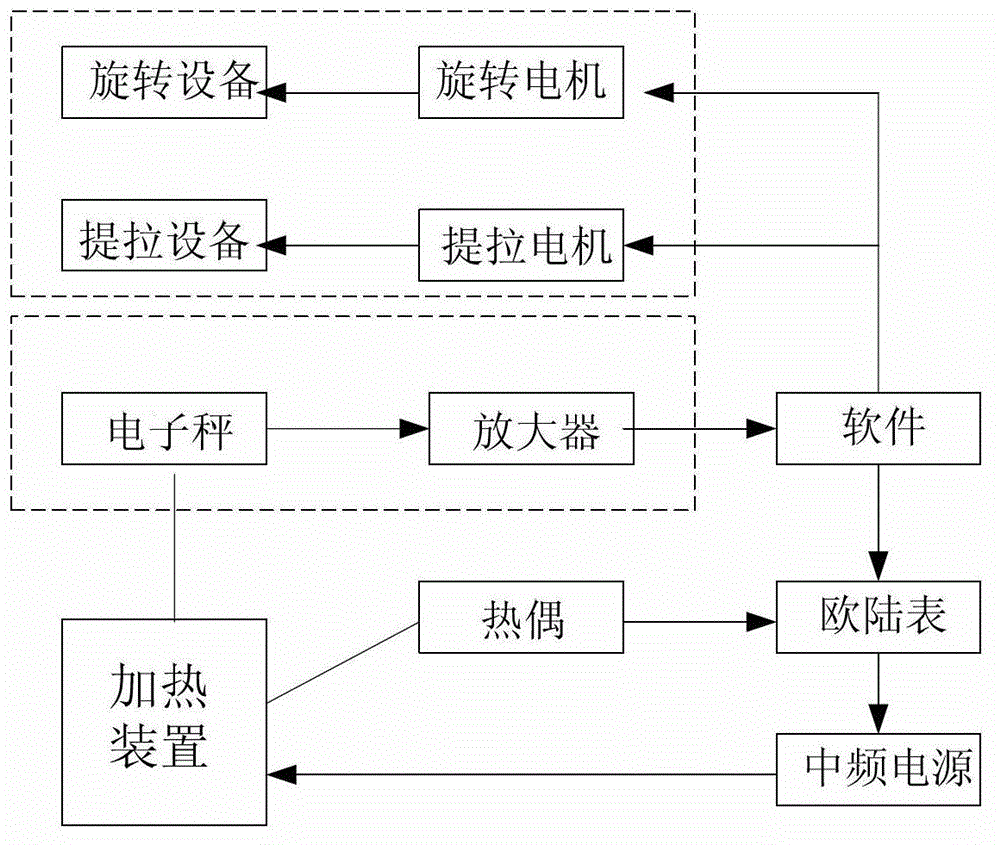

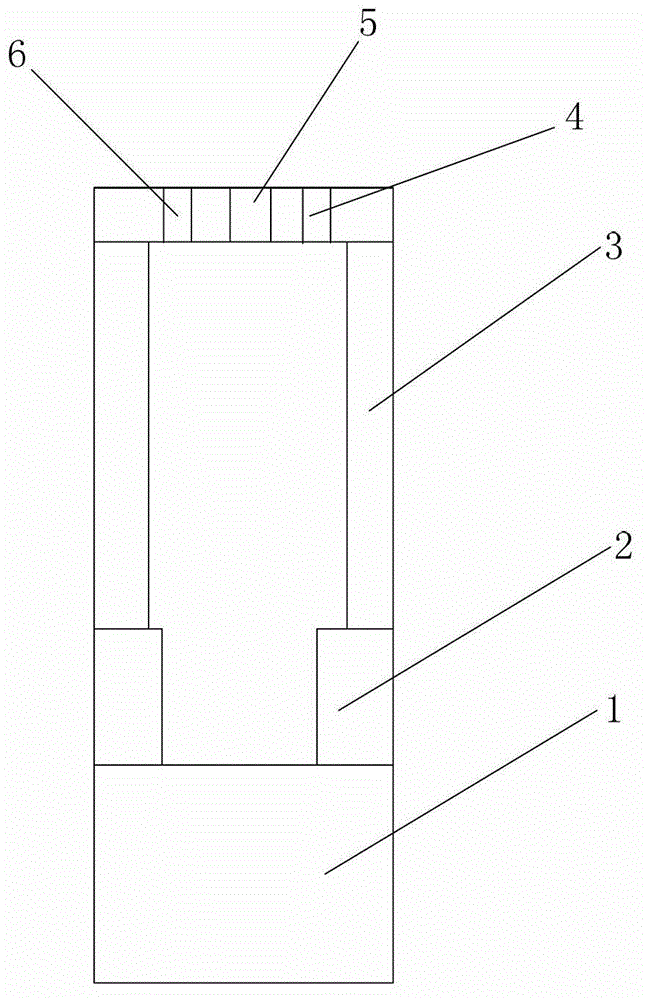

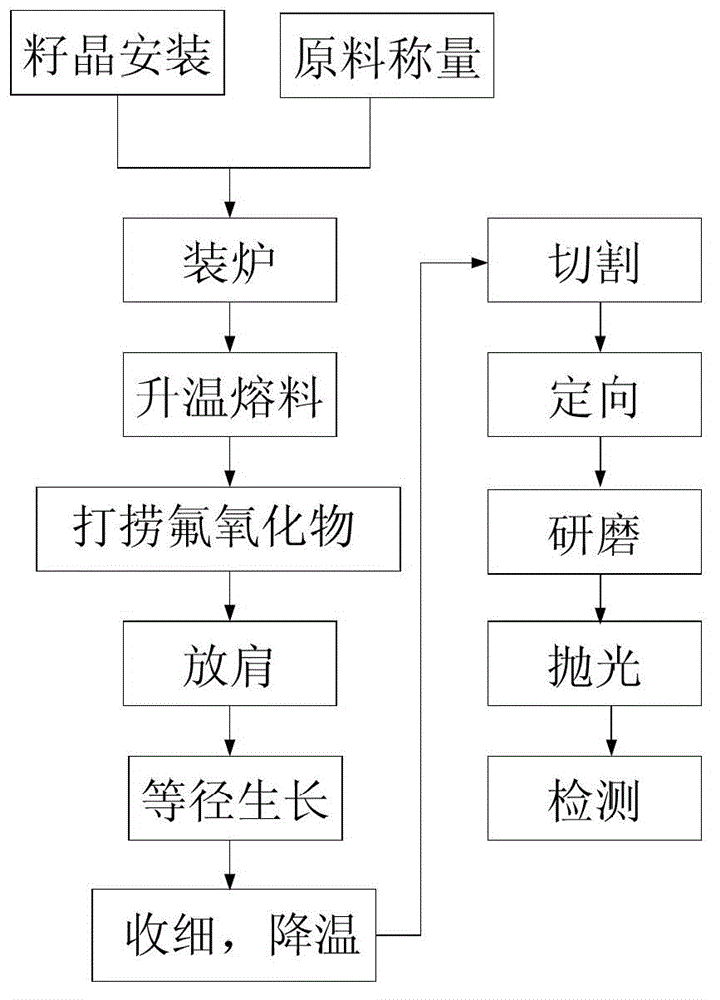

[0047] Accurately weigh 800g of magnesium fluoride powder as the crystal raw material, and the size of the iridium crucible is ф100×90mm. Raw materials are vacuum protected to minimize the contact between raw materials and air. Put the raw materials into the crucible in the crystal growth furnace, install the seed crystal and debug the pulling equipment, flow nitrogen gas in the furnace, start the crystal growth software, set the relevant parameters, the pulling speed of the pulling motor is 1.1mm / h, the rotating motor The rotation speed is 8r / min, and the nitrogen flow rate is 0.4m 3 / h, the number of times of salvage is 5 times, and the temperature of the seed crystal is 1120 ℃. Start to heat up and melt the raw materials, salvage the oxyfluoride, and lower the seed crystal. When the crystal grows to a suitable size, close the program, and the motor will enter manual control. Adjust the speed of the motor to quickly remove the crystal from the liquid surface. After an hour...

Embodiment 2

[0050] Accurately weigh 900g of magnesium fluoride powder as the crystal raw material, and the size of the iridium crucible is ф100×90mm. Raw materials are vacuum protected to minimize the contact between raw materials and air. Put the raw materials into the crucible in the crystal growth furnace, install the seed crystal and debug the pulling equipment, flow nitrogen gas in the furnace, start the crystal growth software, set the relevant parameters, the pulling speed of the pulling motor is 1.1mm / h, the rotating motor The rotation speed is 8r / min, and the nitrogen flow rate is 0.4m 3 / h, the number of times of salvage is 5 times, and the temperature of the seed crystal is 1120 ℃. Start to heat up and melt the raw materials, salvage the oxyfluoride, and lower the seed crystal. When the crystal grows to a suitable size, close the program, and the motor will enter manual control. Adjust the speed of the motor to quickly remove the crystal from the liquid surface. After an hour...

Embodiment 3

[0053] Accurately weigh 1000g of magnesium fluoride powder as the crystal raw material, and the size of the iridium crucible is ф100×90mm. Raw materials are vacuum protected to minimize the contact between raw materials and air. Put the raw materials into the crucible in the crystal growth furnace, install the seed crystal and debug the pulling equipment, flow nitrogen gas in the furnace, start the crystal growth software, set the relevant parameters, the pulling speed of the pulling motor is 1.1mm / h, the rotating motor The rotation speed is 8r / min, and the nitrogen flow rate is 0.4m 3 / h, the number of times of salvage is 5 times, and the temperature of the seed crystal is 1120 ℃. Start to heat up and melt the raw materials, salvage the oxyfluoride, and lower the seed crystal. When the crystal grows to a suitable size, close the program, and the motor will enter manual control. Adjust the speed of the motor to quickly remove the crystal from the liquid surface. After an hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com