Atomic vapor sampling method and device based on electro-deposition and electro-heat

A technology of electrothermal atom and sample injection device, which is applied in the field of instrument analysis to achieve the effects of increasing primary ionization efficiency, reducing matrix interference and reducing working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

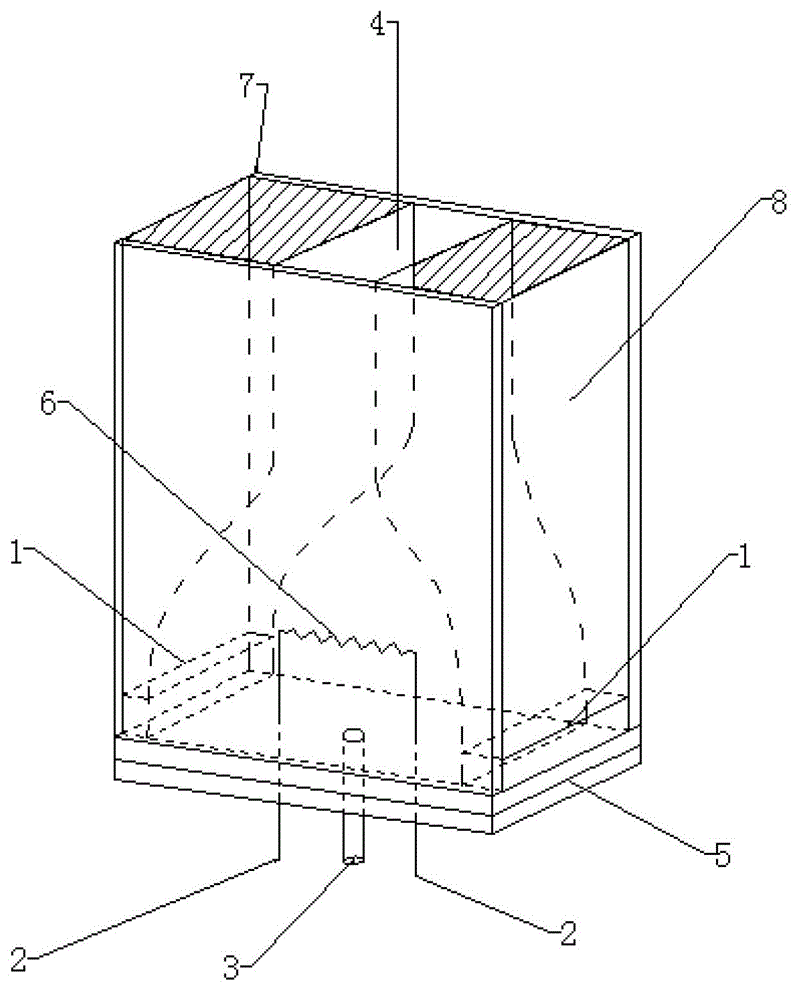

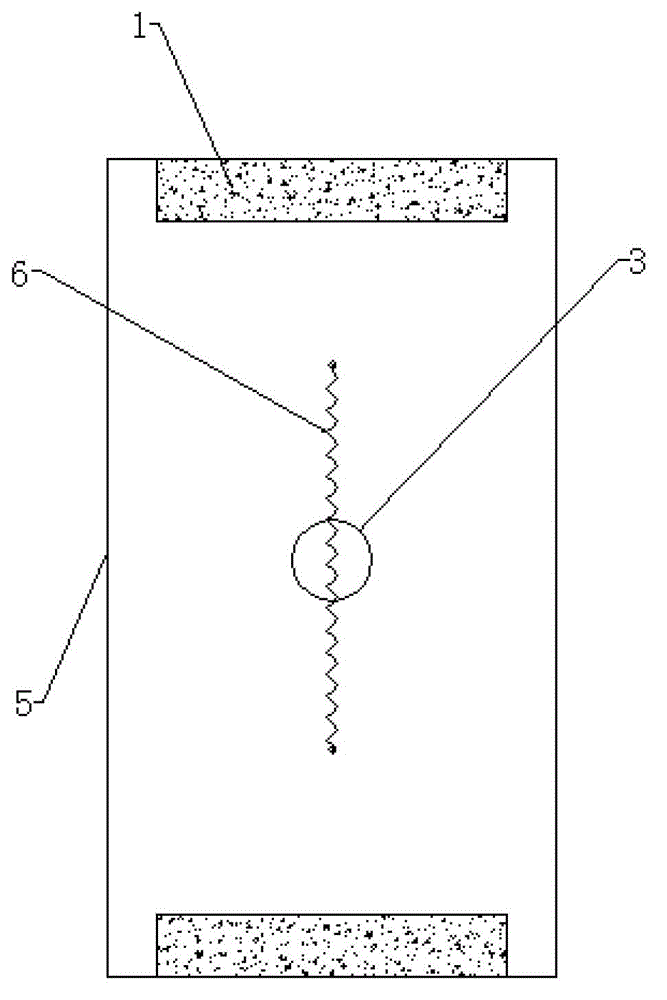

[0031] Embodiment 1: as figure 1 As shown, the evaporation chamber is composed of heat-resistant glass 7, 8 and a heat-resistant glass bottom plate 5, the sample inlet 3 and the exhaust port 4 form an air intake system, the platinum-plated electrolytic electrode 1 is at both ends of the plate, and the tungsten heating wire 6 The two ends pass through the bottom plate 5 to connect the wire 2, and the opposite side is the exhaust port 4. The power supply for heating the carrier gas through the injection port is a feedback current power supply, which can realize precise temperature control.

[0032] Standard solution Cr (Cr 3+ ) after entering from the injection port 3, enter the mixed gas of 95% argon and 5% hydrogen at 15ml / min through the injection port 3, electrolyze under the stirring of the carrier gas, and use constant potential deposition, the deposition potential is -1.3V, At this time, the two electrodes 1 are connected to the positive pole of the DC power supply thr...

Embodiment 2

[0035] Embodiment 2: as figure 1 As shown, the evaporation chamber is composed of quartz 7, 8 and a heat-resistant glass bottom plate 5, the sample inlet 3 and the exhaust port 4 form an air intake system, the platinum-plated electrolytic electrode 1 is at both ends of the plate, and the tungsten heating wire 6 is at both ends Connect the wire 2 through the bottom plate 5, and the opposite side is the exhaust port 4.

[0036] The implementation process is: the standard solution Cd 2+ After entering from the injection port 3, the mixed gas carrier gas of 96% helium and 4% hydrogen enters through the injection port 3 at 20ml / min for electrolysis under stirring, adopts constant current deposition, and the current is 2A. At this time, the electrolysis electrode 1 passes through The wire is connected to the positive pole of the DC power supply, and the heating wire 6 is connected to the negative pole of the DC power supply through the wire 2. After the enrichment of the analyte is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com