Aqueous zinc ion energy storage device

A zinc ion and energy storage technology, applied in the field of energy storage devices, can solve problems such as incomplete desolvation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

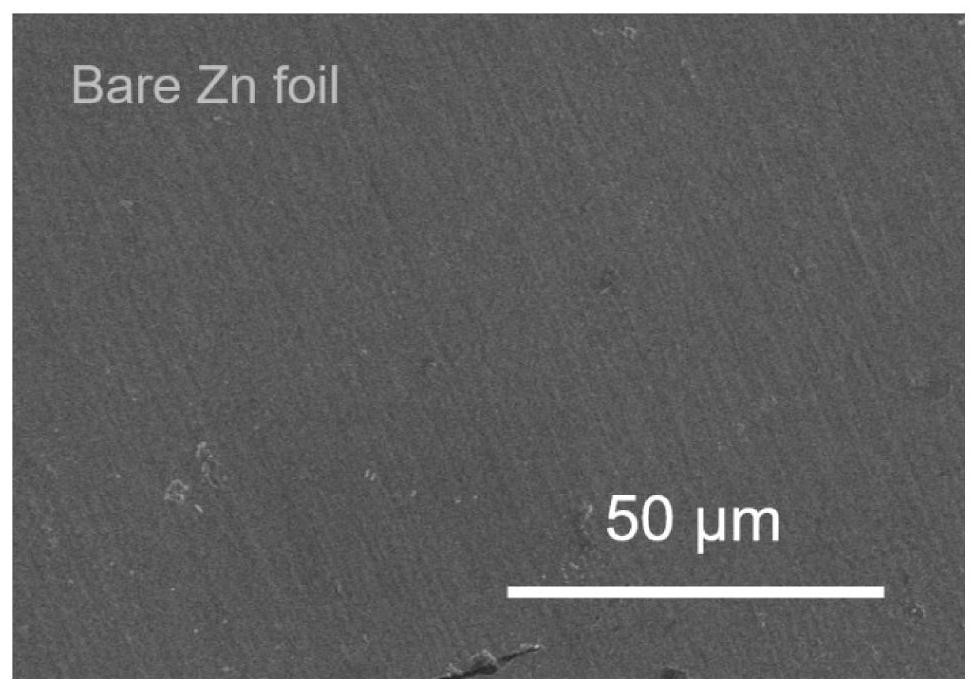

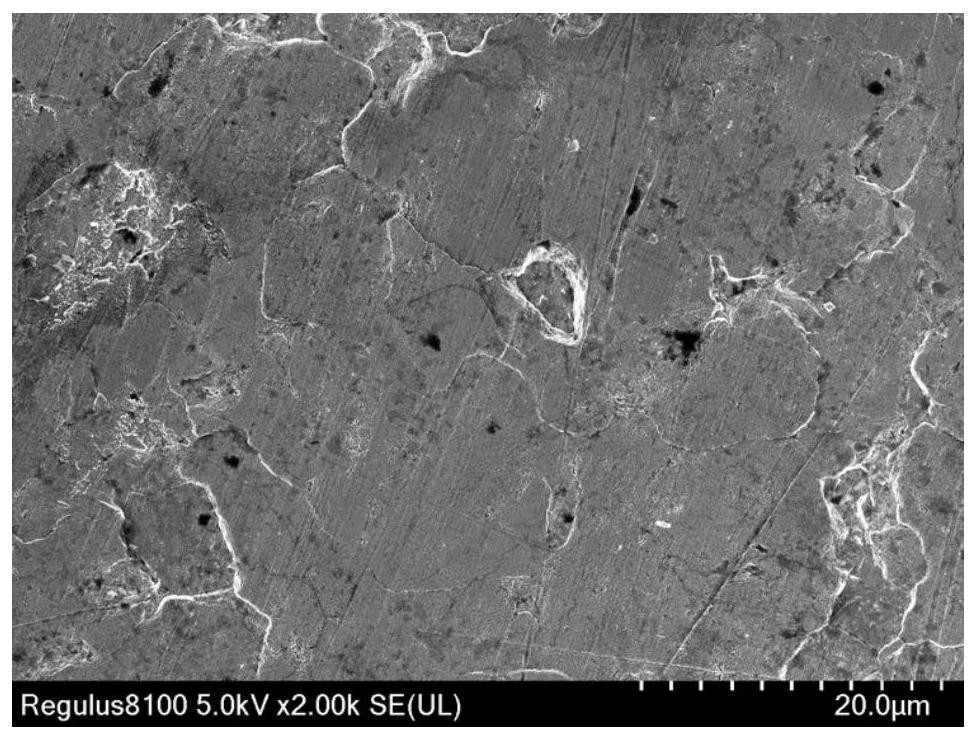

[0033] This embodiment provides a water-based zinc-ion battery, including a positive electrode, a negative electrode, a separator, and an electrolyte. The electrolyte includes a solvent and a solute, and the electrolyte also includes a water-soluble chelating agent EDTA sodium salt with a concentration of 0.05M. The solute is ZnSO 4 , the solvent is deionized water. The negative electrode is a dense metal zinc foil, and the positive electrode includes a conductive substrate and an active material, wherein the active material is MnO 2 , The conductive substrate is carbon paper.

[0034] The preparation method of the aqueous zinc-ion battery comprises the following steps:

[0035]The first step: zinc metal sheet pretreatment: the zinc metal sheet with a thickness of 0.1 mm was ultrasonically cleaned three times with deionized water and absolute ethanol, each time for 10 minutes, and then dried in a blast oven at 70°C. The above-mentioned dried metal sheets are blasted into zi...

Embodiment 2

[0042] This embodiment provides a water-based zinc-ion battery, including a positive electrode, a negative electrode, a separator, and an electrolyte. The electrolyte includes a solvent and a solute, and the electrolyte also includes a water-soluble chelating agent EDTA sodium salt with a concentration of 0.05M. The solute is ZnSO 4 , the solvent is deionized water. The negative electrode is a dense metal zinc foil, and the positive electrode includes a conductive substrate and an active material, wherein the active material is V 2 o 5 , The conductive substrate is carbon paper.

[0043] The preparation method of this aqueous zinc ion battery comprises the steps:

[0044] The first step: zinc metal sheet pretreatment: the zinc metal sheet with a thickness of 0.1 mm was ultrasonically cleaned three times with deionized water and absolute ethanol, each time for 10 minutes, and then dried in a blast oven at 70°C. The above-mentioned dried metal flakes are blasted into zinc me...

Embodiment 3

[0049] This embodiment provides an aqueous zinc-ion battery, including a positive electrode, a negative electrode, a separator, and an electrolyte. The electrolyte includes a solvent and a solute, and the electrolyte also includes a water-soluble chelating agent NTA sodium salt at a concentration of 0.07M. The solute is ZnCl 2 , the solvent is sea water. The negative electrode is a porous zinc metal mesh, and the positive electrode includes a conductive substrate and an active material, wherein the active material is V 2 o 5 , The conductive substrate is carbon cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com