Lithium negative electrode or sodium negative electrode and preparation method and application of lithium negative electrode or sodium negative electrode

A lithium negative electrode and negative electrode technology, which is applied in the field of lithium/sodium batteries, can solve the problems of lithium battery and sodium battery capacity attenuation, cycle life, etc., to suppress the formation of sodium dendrites, promote uniform deposition, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of a lithium negative pole or a sodium negative pole. The preparation method of lithium negative pole or sodium negative pole mentioned here refers to the preparation method of lithium negative pole or the preparation method of sodium negative pole, because in the preparation method of lithium negative pole and sodium negative pole in the present invention, only the difference between lithium and sodium materials , and the rest of the preparation process is the same, so the two are put together for explanation.

[0035] The preparation method of the lithium negative pole or the sodium negative pole comprises the following steps:

[0036] An anti-perovskite solid electrolyte is provided, and then the anti-perovskite solid electrolyte is melted to obtain a molten anti-perovskite solid electrolyte, and the molten anti-perovskite solid electrolyte is coated on the surface of the current collector, thereby A layer of anti-perovski...

Embodiment 1

[0060] A preparation method of a lithium negative electrode and a lithium-sulfur battery.

[0061] Wherein the preparation method of lithium negative electrode comprises the following steps:

[0062] S11. In the glove box (control H 2 O≤20ppm, O 2 ≤200ppm), put 0.2mol LiOH (purity ≥99%, produced by alladin company) and 0.1mol LiCl (purity ≥99%, produced by alladin company) into a mortar for grinding and mixing, and then put it into an alumina crucible Heat to (345±15)°C and keep vacuuming for 24h, the reaction equation is LiCl+2LiOH=Li 3 OCl+H 2 O; Lithium ion conductivity can be obtained at 10 -3 ~10 -5 range of antiperovskite solid electrolyte Li 3 OCl.

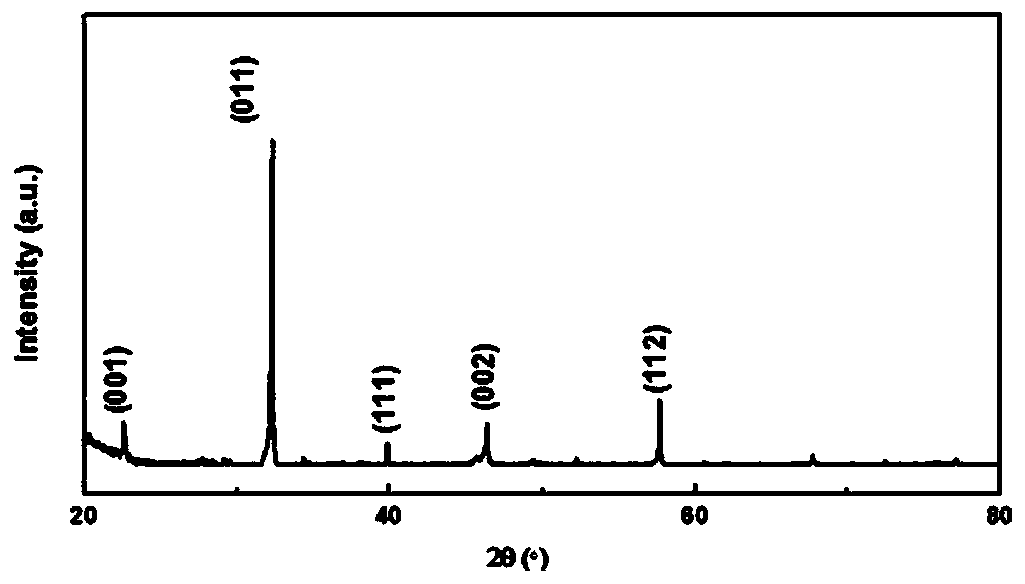

[0063] For verification, Li 3 OCl, carry out XRD test to the substance that S11 obtains, the result is as follows figure 1 shown. From figure 1 It can be seen that the resulting reaction product is Li 3 OCl.

[0064] S12. the molten anti-perovskite solid electrolyte Li obtained in step S11 3 OCl is added dropw...

Embodiment 2

[0077] A preparation method of a lithium negative electrode and a lithium-sulfur battery.

[0078] Wherein the preparation method of lithium negative electrode comprises the following steps:

[0079] S21. In the glove box (control H 2 O≤20ppm, O 2 ≤200ppm), put 0.2mol LiOH (purity ≥99%, produced by aladdin company) and 0.1mol LiCl (purity ≥99%, produced by aladdin company) into a mortar for grinding and mixing, and then put it into an alumina crucible Heat to (345±15)°C and keep vacuuming for 24h, the reaction equation is LiCl+2LiOH=Li 3 OCl+H 2 O; Lithium ion conductivity can be obtained at 10 -3 ~10 -5 range of antiperovskite solid electrolyte Li 3 OCl.

[0080] S22. The antiperovskite solid electrolyte Li obtained by step S21 will be obtained 3 OCl is made into a dense ceramic sheet; using magnetron sputtering deposition method (sputtering power 200W, argon gas pressure 3m torr, argon flow rate 3sccn, sputtering time 20 minutes), the ceramic sheet is sputtered on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com