A miniature atomization/ionization detection device and method thereof

An ionization detection and atomization technology, applied in the field of instrument analysis, can solve the problems of unfavorable instrument miniaturization, strong background light interference, high operating temperature, and achieve the effects of avoiding background light interference, increasing optical path length, and increasing ionization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

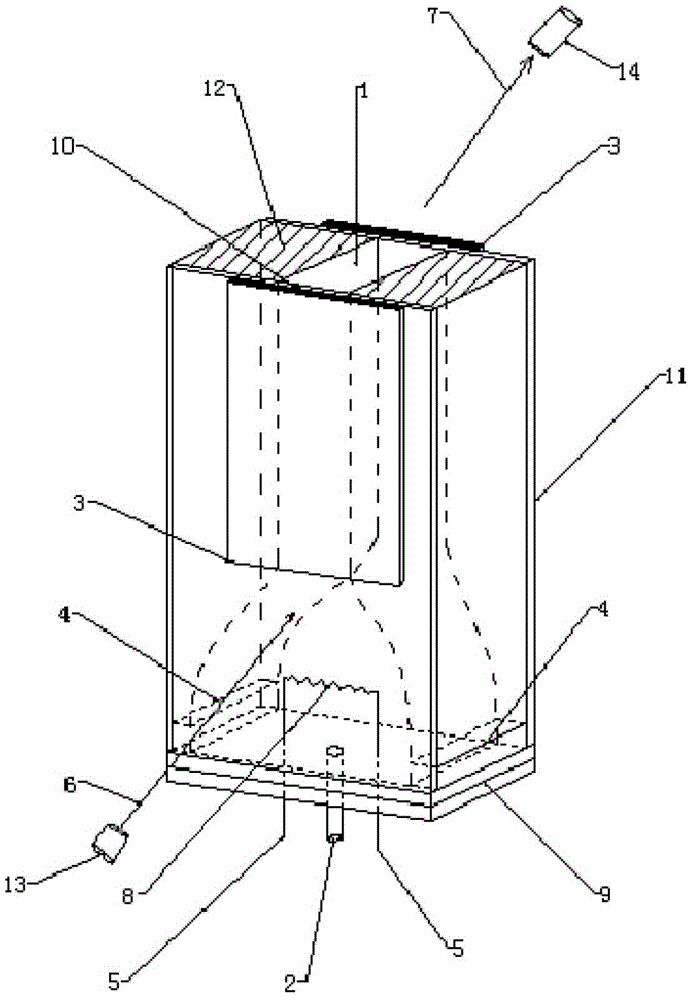

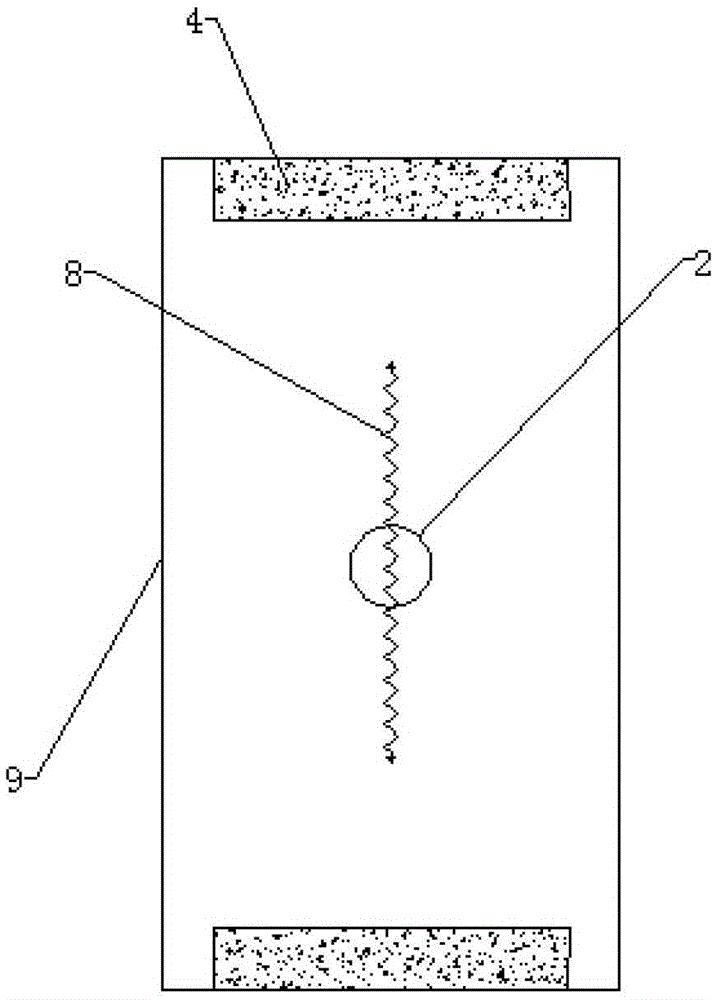

[0038] Embodiment 1: as figure 1 As shown, the device is composed of quartz 12 (thickness 4mm) and flat quartz 11 (thickness 0.8mm, distance between two planes is 4mm), electrolytic chamber (4mm×50mm, upper bottom 6mm, lower bottom 12mm), the surface of the flat quartz 11 has a silver-plated surface 10 (8mm×80mm), the copper electrode plate 3 (1mm×10mm×70mm) is closely combined on the silver-plated surface 10, and the copper electrode plate 3 is connected to the high High-frequency high-voltage power supply (10KV, 10MHZ), heat-resistant glass bottom plate 9 has a sample inlet 2 (diameter 1mm), exhaust port 1 (diameter 2mm), heating wire 8 passes through the bottom plate 9 and connects to the wire 5, when electrolysis: Connect the two electrodes 4 to the DC power supply through wires, and connect the two ends of the heating wire 8 to the negative pole of the DC power supply through the wire 5; The lamp 13 generates incident light 6, which enters the dielectric barrier discharg...

Embodiment 2

[0042] Embodiment 2: as figure 1 As shown, the device is a discharge chamber (8mm×16mm×100mm) composed of heat-resistant glass 12 (thickness 8mm) and plane heat-resistant glass 11 (thickness 1mm, distance between two planes is 8mm), electrolytic chamber (8mm×60mm , upper bottom 16mm, lower bottom 24mm), the surface of the flat quartz 11 has an aluminum-plated mirror 10 (18mm×110mm), the copper electrode plate 3 (1mm×20mm×100mm) is tightly combined on the mirror 10, and the copper electrode plate 3 is connected by a wire High-frequency high-voltage power supply (30KV, 40MHZ), heat-resistant glass bottom plate 9 has a sample inlet 2 (diameter 1mm), exhaust port 1 (diameter 2mm), heating wire 8 passes through the bottom plate 9 and connects to the wire 5, when electrolysis : Connect the two platinum-plated gold electrodes 4 to the DC power supply through wires, and connect the two ends of the heating wire 8 to the negative pole of the DC power supply through the wire 5; when heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com