Method and apparatus for eddy-based electronically-controlled scanning and monitoring

A monitoring device and eddy current detection technology, which is applied in measurement devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of high difficulty and high cost of automatic detection technology, low detection efficiency, manual detection, etc., and achieve device detection efficiency and The effect of high detection accuracy, lower detection cost, and elimination of detection blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

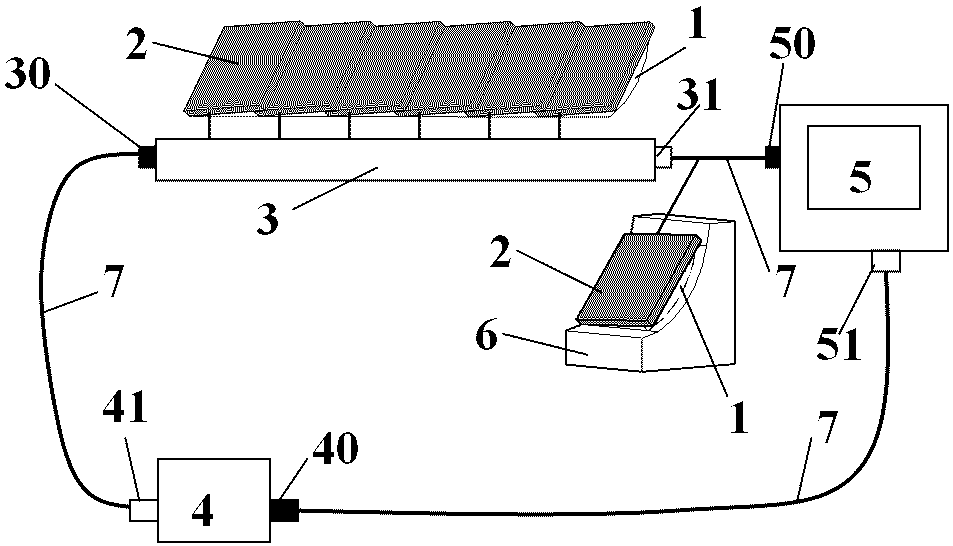

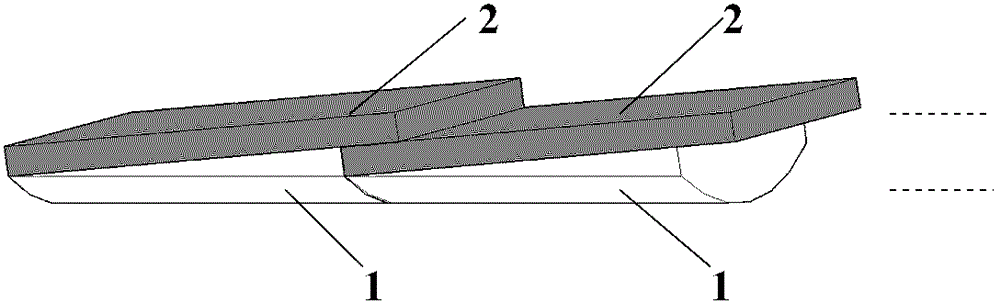

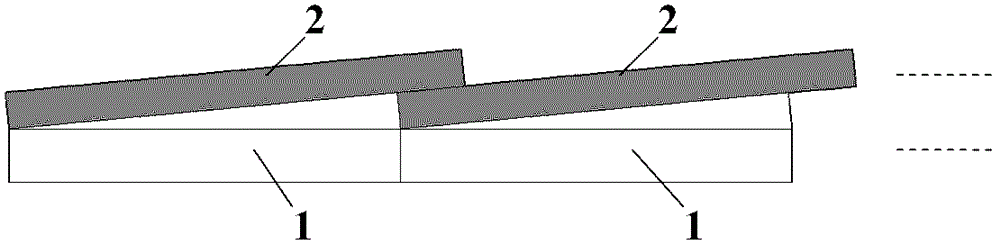

[0029] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 In the shown embodiment, an eddy current electronically controlled scanning and monitoring device for rails in use includes a plurality of probe support inclined blocks 1, a plurality of single-coil eddy current detection probes 2, an array electronic switching on switch 3, a programmable logic The controller 4, the eddy current detector 5, the standard test piece 6, and the signal cable 7 are characterized in that: the end faces 11 of the plurality of probe support slant blocks 1 are arranged in a line and fixed closely; the plurality of single-coil eddy current detection probes 2 is fixed on the inclined plane 10 of a plurality of probe supporting inclined blocks 1 arranged in a line, and there are overlapping parts between the plurality of single-coil eddy current detection probes 2, that is, the edge part of one single-coil eddy current detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com