Defect detecting method of concrete

A defect detection and concrete technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of complex detection conditions, complex hardware and software control systems, and difficulty in array signal beam control, so as to improve the signal-to-noise ratio and resolution. rate, simple to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

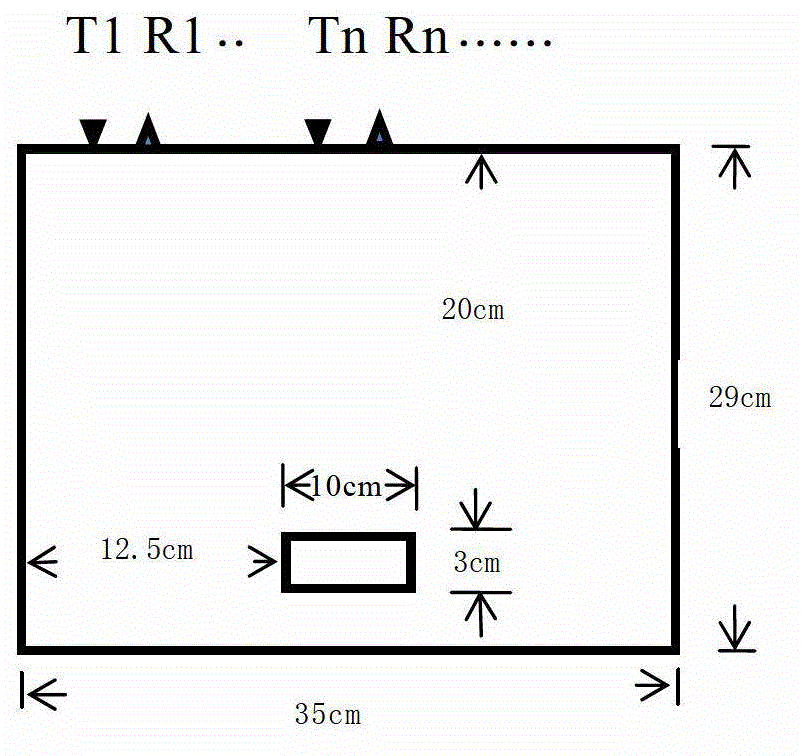

[0017] The technical solutions of the present invention will be described in further detail below through examples.

[0018] In view of the defects of the existing schemes, it is considered to combine the pulse compression technology with the synthetic aperture imaging detection method.

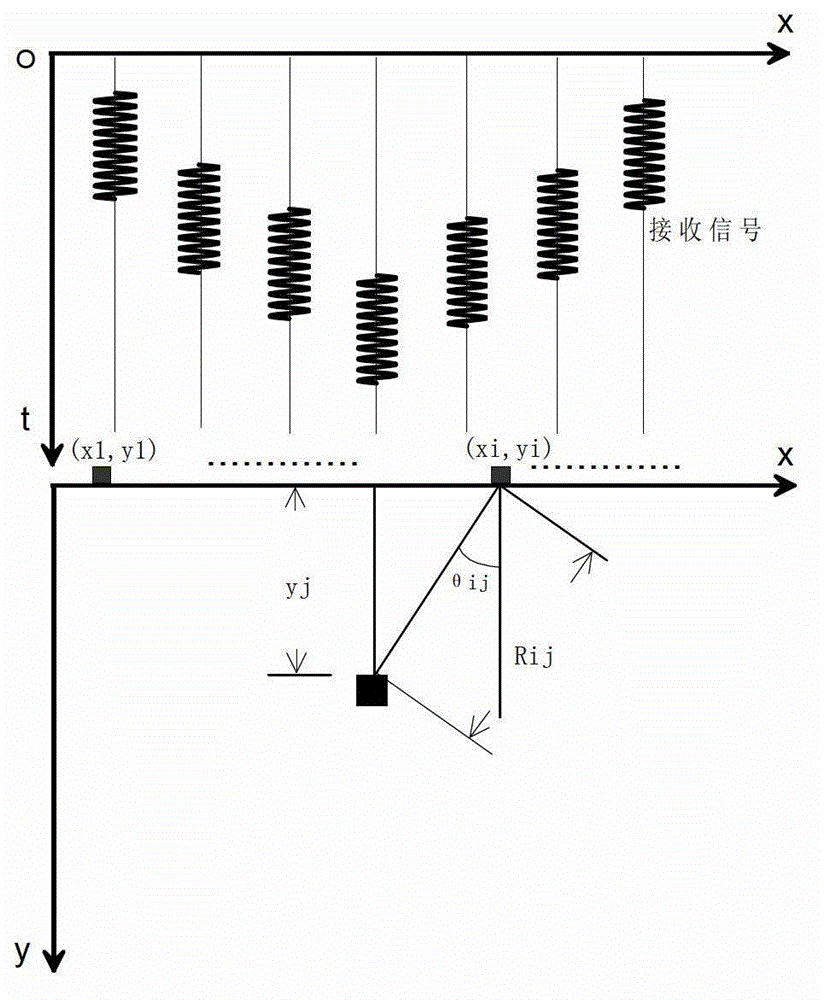

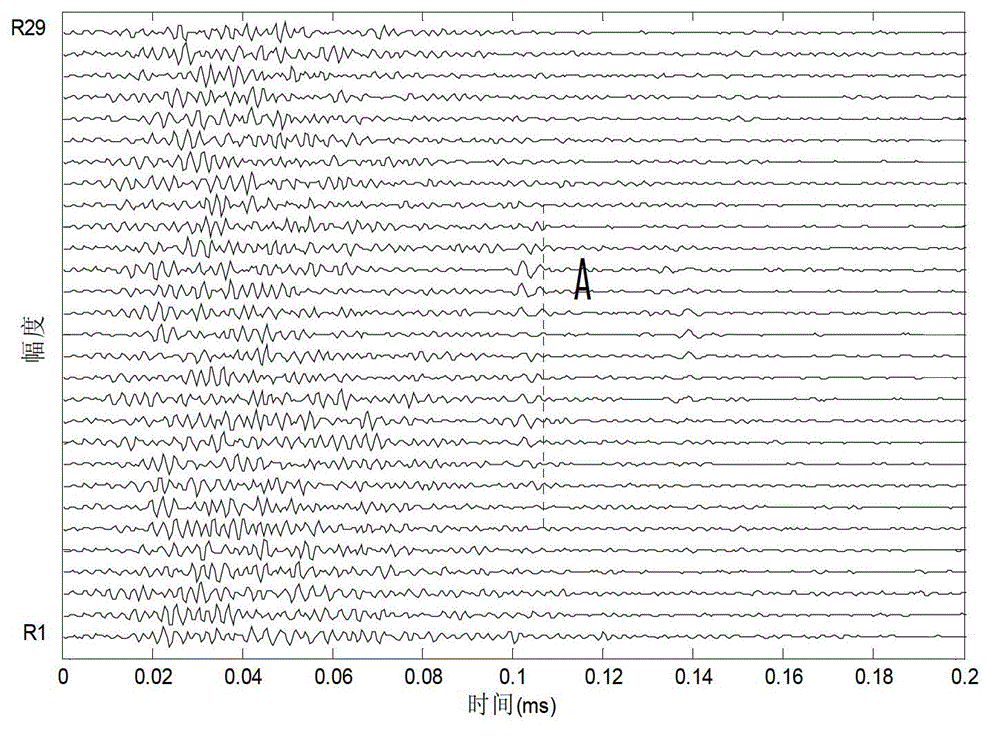

[0019] The synthetic aperture focusing imaging method (SAFT) sequentially transmits and receives echo signals at different positions in space, and coherently superimposes the echo signals at different positions according to the spatial position and phase relationship, thereby forming an equivalent large aperture. This method can effectively improve the signal-to-noise ratio of ultrasonic detection.

[0020] The pulse compression technology is to transmit a wide-time and wide-band chirp signal at the transmitting end, thereby increasing the energy of the transmitted signal, and compressing the wide-pulse chirp signal in the time domain to a very short time at the receiving end through the prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com