Nuclear power plant equipment monitoring system based on optical fiber Bragg grating sensing

An equipment monitoring system and optical fiber grating technology, applied in nuclear power generation, nuclear reactor monitoring, nuclear engineering, etc., can solve problems such as inability to monitor nuclear power plant equipment, achieve good radiation resistance performance, simple results, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

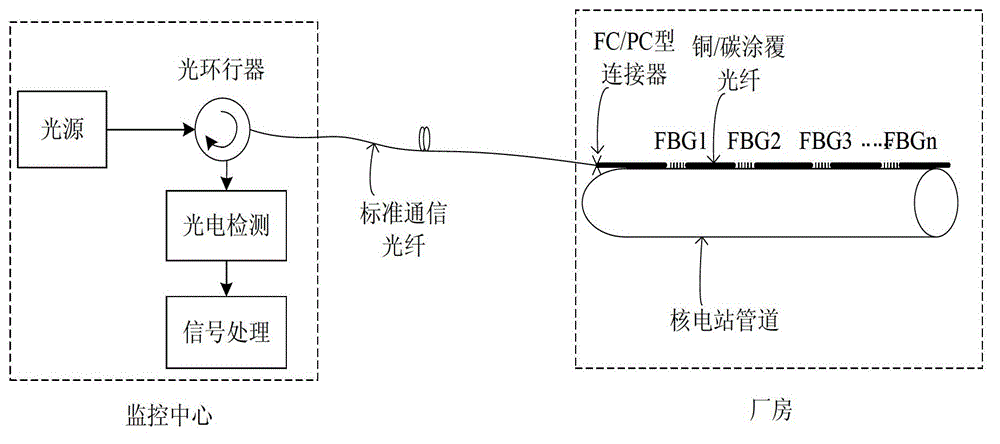

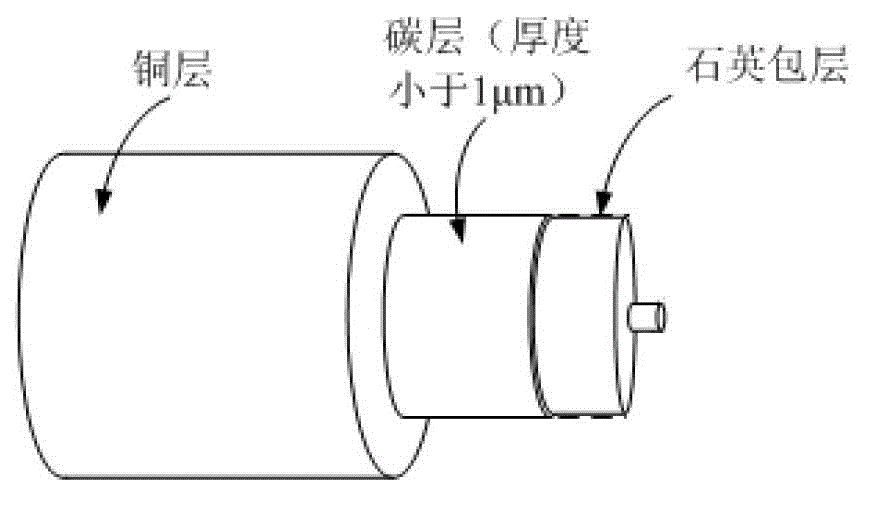

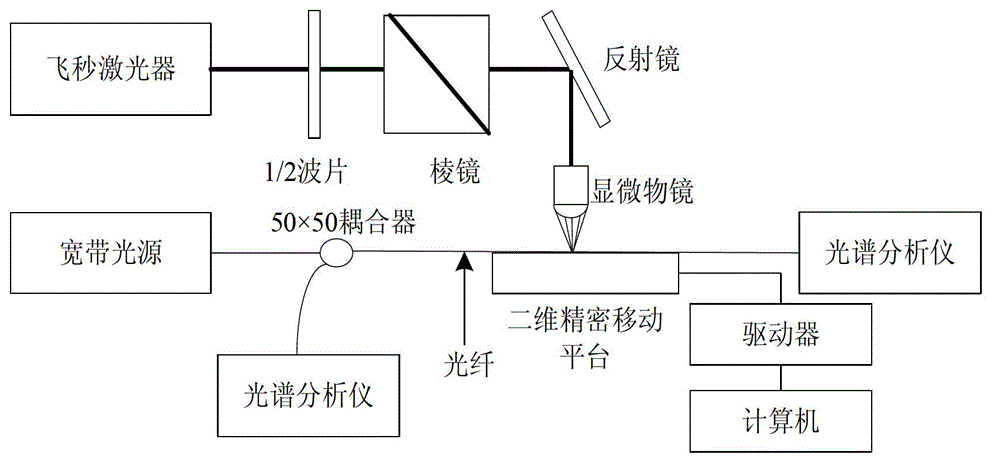

[0020] A nuclear power plant equipment monitoring system based on fiber Bragg grating sensing, including light source, fiber Bragg grating and copper / carbon coated fiber, the fiber grating space is written on the copper / carbon coated fiber or connected by copper / carbon coated fiber, the fiber grating passes through the high temperature Adhesives are pasted on the outer surfaces of pipes and containers in nuclear power plants, fiber gratings are connected to optical circulators through standard communication fibers, and copper / carbon coated fibers are connected to communication fibers through FC / PC connectors. The light emitted by the light source passes through the optical circulator and enters the nuclear power plant through the communication optical fiber. The light reflected by the fiber grating reaches the photodetector through the opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com