Sandwich parallel epitaxial gan pin type α irradiation cell and preparation method

A parallel and epitaxy technology, applied in the field of microelectronics, can solve the problems of large leakage current, easy introduction of surface defects, low energy conversion rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

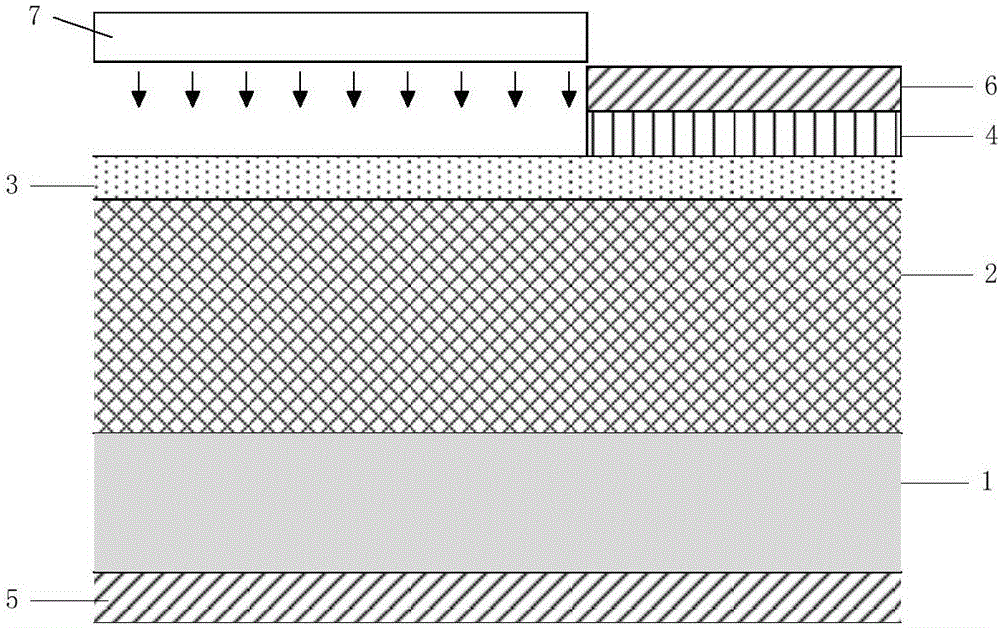

[0042] Embodiment 1, preparation α radiation source is Am 241 , PIN-type α-irradiated cell with sandwich parallel epitaxial GaN with α-radiation source layer thickness of 6 μm.

[0043] Step 1: Make the lower PIN knot.

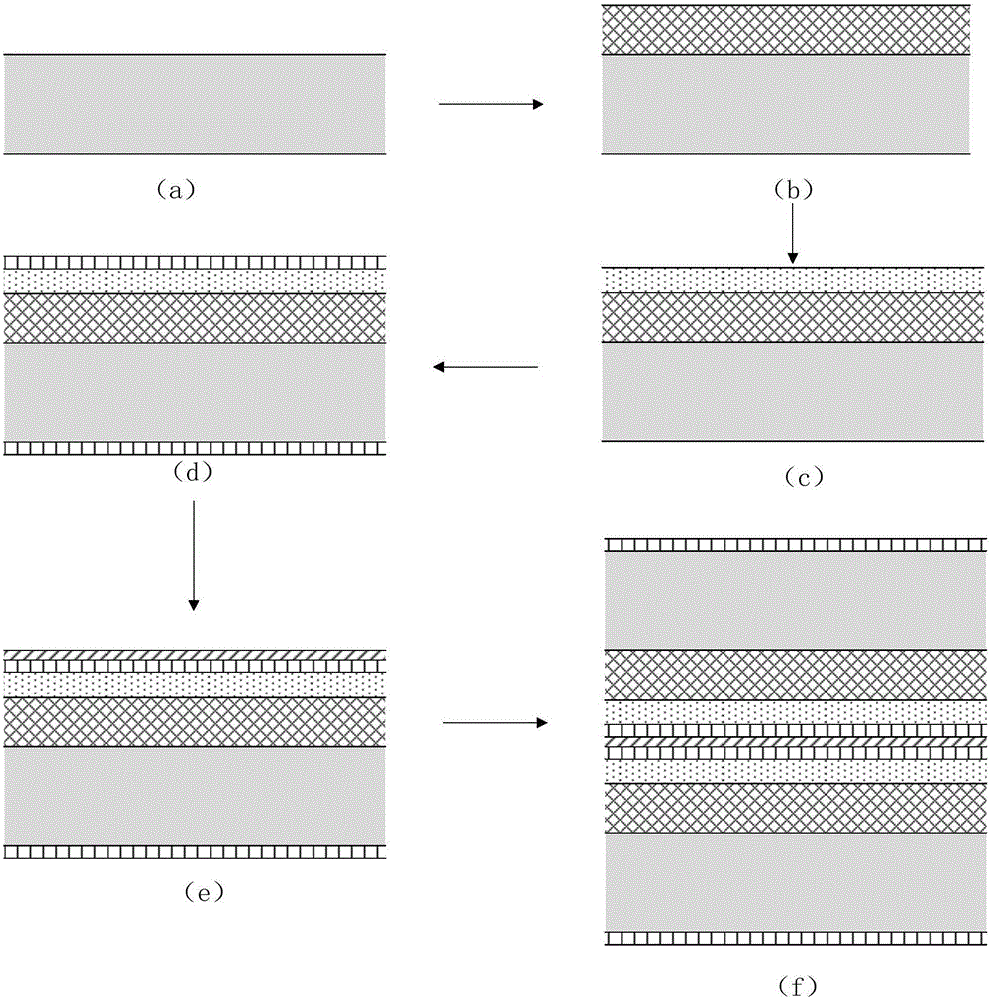

[0044] (1.1) Clean the 4H-SiC sample to remove surface pollutants, such as image 3 (a) shown.

[0045] (1.1.1) The doping concentration is l x 10 18 cm -3 Highly doped n-type 4H-SiC substrate sample in NH 4 OH+H 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove the organic residue on the surface of the sample;

[0046] (1.1.2) Use HCl+H to remove the 4H-SiC sample after removing the surface organic residue 2 o 2 Soak the sample in the reagent for 10 minutes, take it out and dry it to remove ionic pollutants.

[0047] (1.2) Epitaxial growth of N-type low-doped SiC epitaxial layer, such as image 3 (b) shown.

[0048] A nitrogen-doped N-type doped epitaxial layer is epitaxially grown on the cleaned SiC sample by c...

Embodiment 2

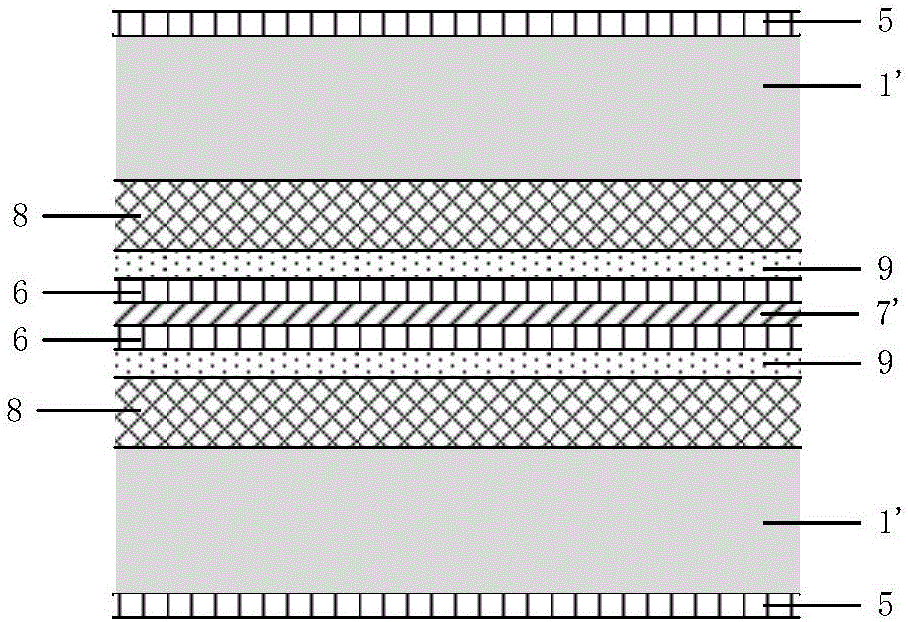

[0062] Embodiment 2, preparation α radiation source is Am 241 , PIN-type α-irradiated cell with sandwich parallel epitaxial GaN with α-radiation source layer thickness of 4 μm.

[0063] Step 1: Make the lower PIN knot.

[0064] 1a) Clean the 4H-SiC sample to remove surface contaminants such as image 3 (a).

[0065] This step is the same as step (1.1) of Example 1.

[0066] 1b) Epitaxial growth of N-type low-doped SiC epitaxial layer, such as image 3 (b).

[0067] A nitrogen-doped N-type doped epitaxial layer is epitaxially grown on the cleaned SiC sample by chemical vapor deposition CVD. The process conditions are: epitaxy temperature is 1570°C, pressure is 100mbar, reaction gas is silane and propane, carrier gas is pure hydrogen, magazine source is liquid nitrogen, and the concentration of nitrogen doping is 2 x 10 15 cm -3 , growth of an N-type low-doped SiC epitaxial layer with a thickness of 25 μm.

[0068] 1c) Epitaxial growth of P-type highly doped GaN epitaxia...

Embodiment 3

[0078] Embodiment 3, preparation α radiation source is Pu 238 , PIN-type α-irradiated cells with sandwich parallel epitaxial GaN with a layer thickness of α-radiation source of 3 μm.

[0079] Step A: Make the upper PIN knot.

[0080] (A1) Clean the 4H-SiC sample to remove surface contaminants, such as image 3 (a).

[0081] This step is the same as step (1.1) of Example 1.

[0082] (A2) A nitrogen-doped N-type low-doped SiC epitaxial layer is epitaxially grown on the cleaned SiC sample by chemical vapor deposition CVD. The process conditions are as follows: the epitaxy temperature is 1570°C, the pressure is 100mbar, the reaction gas is silane and propane, the carrier gas is pure hydrogen, and the magazine source is liquid nitrogen. A nitrogen doping concentration of 3 x 10 15 cm -3 , a N-type low-doped SiC epitaxial layer with a thickness of 30 μm such as image 3 (b).

[0083] (A3) Put the sample after growing the N-type low-doped SiC epitaxial layer into the chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com