Steel having excellent irradiation resistance and used for steel lining of nuclear power plant, and manufacturing method thereof

A manufacturing method and anti-irradiation technology, which is applied in the field of steel for nuclear power plant steel lining and its manufacturing, can solve the problems of unfavorable anti-irradiation performance of steel, increase of production cost, low purity of steel, etc., and achieve excellent anti-irradiation Embrittlement performance, low cost, and effects of less inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the production method of Example 1, the molten steel is smelted in a converter, refined outside the furnace, and cast into a continuous casting slab. In continuous casting, the superheat of the tundish is 21°C, and the casting speed is 1.7m / min. See Example 1 in Table 1 for the smelting composition, Table 2 for the heating and rolling process of the continuous casting slab, Table 3 for the heat treatment process, and Table 4 for the mechanical properties.

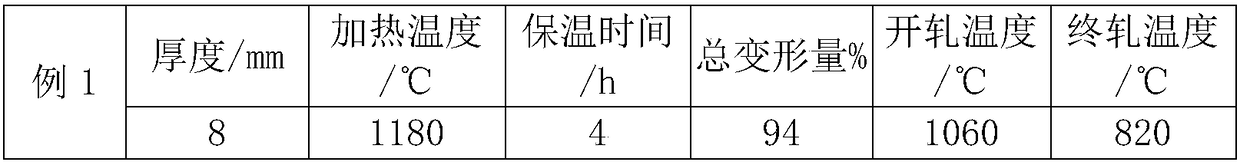

[0037] Table 2 Heating and rolling process

[0038]

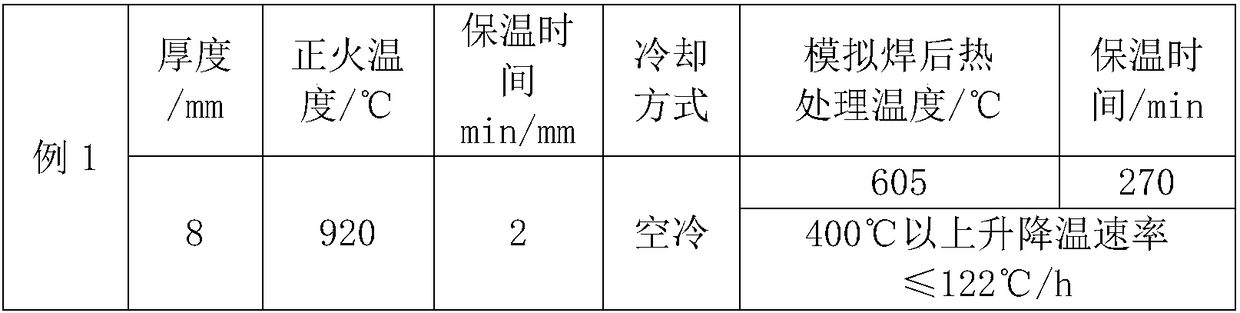

[0039] Table 3 heat treatment process

[0040]

[0041] Table 4 Mechanical properties of steel plates

[0042]

[0043] After normalizing, the 8mm steel plate meets the requirements of the RCC-M specification, and the steel plate has good comprehensive mechanical properties.

Embodiment 2

[0044] In the production method of embodiment 2, the molten steel is smelted in a converter, refined outside the furnace, and cast into a continuous casting slab. In continuous casting, the superheat of the tundish is 22°C, and the casting speed is 1.8m / min. The smelting composition is shown in Example 2 in Table 1, the continuous casting slab heating and rolling process is shown in Table 5, the heat treatment process is shown in Table 6, and the mechanical properties are shown in Table 7.

[0045] Table 5 Heating and rolling process

[0046]

[0047] Table 6 heat treatment process

[0048]

[0049] Table 7 Mechanical properties of steel plates

[0050]

[0051] After the 12mm steel plate is normalized and simulated post-weld heat treatment, all performance indicators meet the requirements of the RCC-M specification, and the steel plate has good comprehensive mechanical properties.

Embodiment 3

[0052] In the production method of embodiment 3, the molten steel is smelted in a converter, refined outside the furnace, and cast into a continuous casting slab. In continuous casting, the superheat of the tundish is 22°C, and the casting speed is 1.5m / min. See Example 3 in Table 1 for the smelting composition, Table 8 for the heating and rolling process of the continuous casting slab, Table 9 for the heat treatment process, and Table 10 for the mechanical properties.

[0053] Table 8 Heating and rolling process

[0054]

[0055] Table 9 heat treatment process

[0056]

[0057] Table 10 Mechanical properties of steel plates

[0058]

[0059] The yield strength and tensile strength of 16mm steel plate after normalizing treatment are 360MPa and 504MPa respectively, and the impact energy absorbed at -20°C reaches 260J; The absorbed energy reaches 270J (yield strength ≥ 265MPa, tensile strength: 410-530MPa). After normalizing and simulated post-weld heat treatment, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com