Packaging process of blue light light-emitting diode (LED) converting to white light through secondary excitation

A technology of secondary excitation and packaging technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of retinal cell damage, high energy, loss, etc., and achieve outstanding substantive features, broad application prospects, and significant technological progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

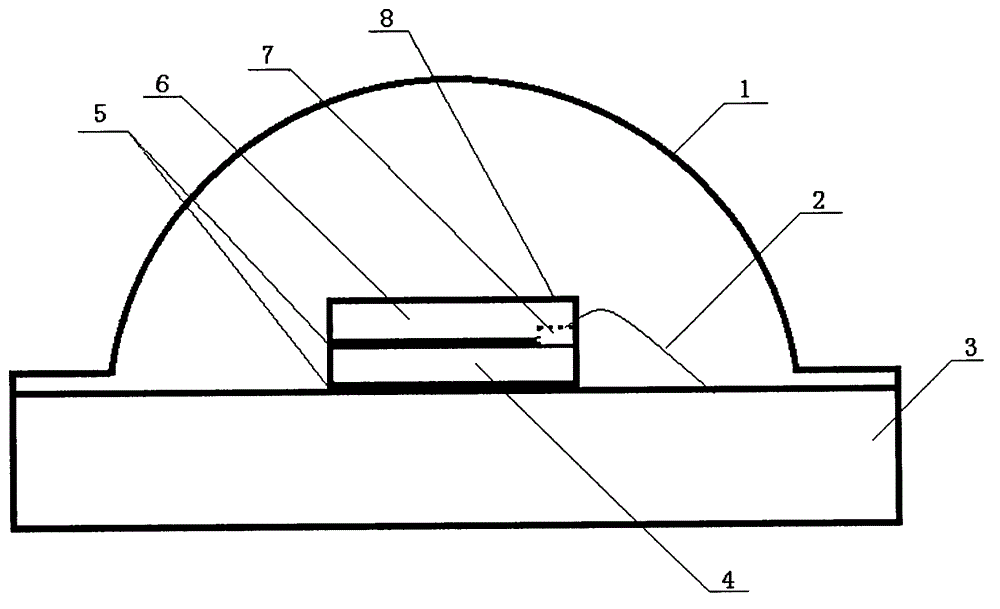

[0015] As shown in the figure, the encapsulation process of blue LED secondary excitation to convert white light includes prefabricated LED fluorescent lampshade, blue LED chip, YAG yellow phosphor, and substrate, and is characterized in that: the YAG yellow phosphor and blue LED chip Stacked from top to bottom and placed in a prefabricated LED fluorescent lampshade, and consolidated with the substrate together with the lower plane of the prefabricated LED fluorescent lampshade.

[0016] The blue LED chip is a single-electrode chip with a vertical structure.

[0017] The substrate is provided with a positive electrode area and a negative electrode area; and the substrate is a ceramic substrate, a copper alloy substrate or an aluminum alloy substrate.

[0018] A viscose-type filler or gel is placed between the blue LED chip and the YAG yellow fluorescent powder, and between the blue LED chip and the substrate.

[0019] The blue LED chip is coated with YAG yellow phosphor, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com