Method for manufacturing biologically-fermented straw nutrition forage grass at low temperature for beef

A production method, straw biological technology, applied in the field of production of herbivore edible forage grass, can solve the problems of limitation of straw forage processing, modulation and feeding, difficulty in homogenization of quality, and great influence of climatic conditions, so as to achieve uniform product quality. Stable quality, easy processing and production, strong production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The following examples illustrate the method for producing beef cattle fattening straw bio-fermentation nutritional forage grass under low temperature conditions according to the present invention, but the scope of the present invention is not limited in any way.

[0062] one. Preparation of Biological Grass Storage Fermentation Agent

[0063] From Filamentous fungi, Bacillus subtilis, Candida utilis, Streptococcus faecium and Pediococcus acidilactici

[0064] Starting from five bacterial strains, three kinds of dried bacterial cultures were obtained by the following cultivation method, and then these three dried bacterial cultures were uniformly mixed in a weight ratio of 2:2:1 to make a biological grass starter.

[0065] 1. Obtaining dry bacteria of small filamentous fungi by solid-state fermentation culture method

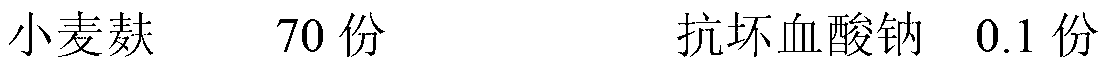

[0066] Various raw material components and their weight proportions in the solid medium used are as follows:

[0067]

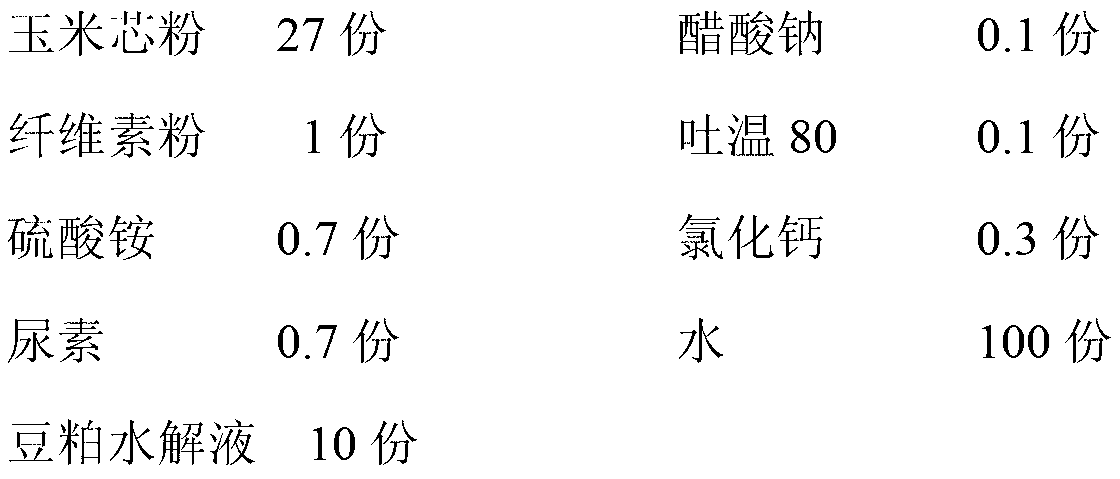

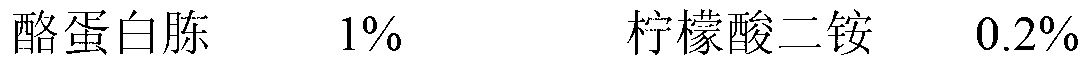

[0068]

[0069] First, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com