Method for producing alcohol by utilizing apple peel residues

A technology for apple peels and residues, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of waste of resources, low utilization rate of apple peels, etc., and achieve low utilization rate, low cost, The effect of abundant raw material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

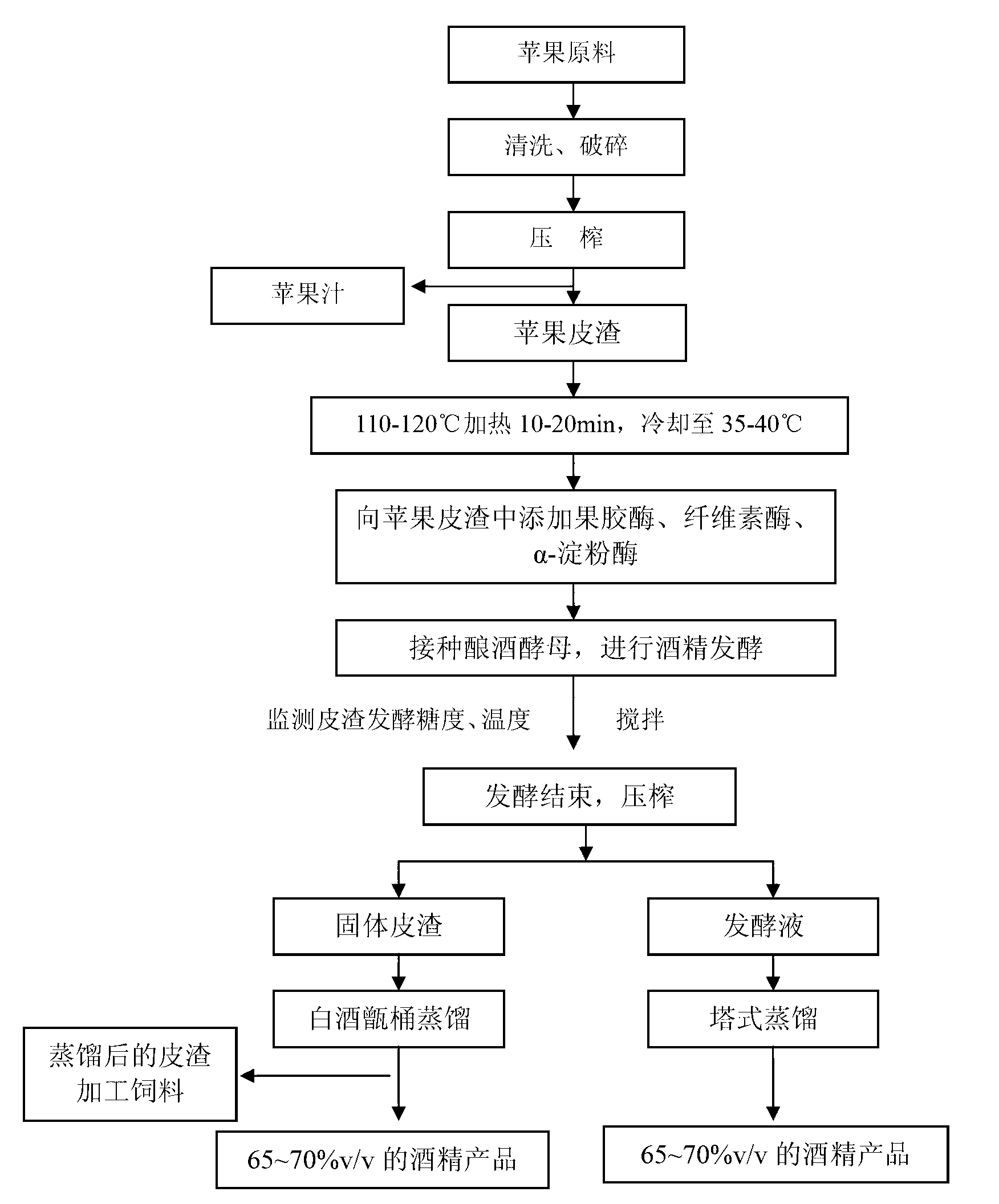

Image

Examples

Embodiment 1

[0028] Wash, crush, and squeeze Xiaoguoguang apples to separate fresh apple peels; put the apple peels into a high-pressure steamer and heat them to 120°C, keep them for 10 minutes, then cool them to 35°C through cooling coils, and put them into the fermentation tank. The amount of feed is 80% of the tank volume; add 20 mg of activated pectinase, 20 mg of α-amylase and 4 mg of cellulase to each liter of apple pomace, stir well, and react for 6 hours; Inoculate Saccharomyces cerevisiae with good activity in the pomace, the dosage is 250 mg per liter of apple pomace, and the fermentation temperature is controlled at 20-28 degrees; during the alcoholic fermentation, the fermentation temperature and sugar content are monitored once every 8 hours; Stir 4 times, 5-10 minutes each time, stir 6 times a day, 10-20 minutes each time during the vigorous fermentation period; when the sugar content is lower than 3g / L, the fermentation ends, and the fermentation time is 4 days; press and fer...

Embodiment 2

[0030] Wash, crush, and squeeze the Red Fuji apples to obtain fresh apple pomace; heat the apple pomace in a high-pressure steamer to 120°C, keep it for 20 minutes, cool it to 40°C through a cooling coil, and put it into a fermentation tank. The amount of feed is 80% of the tank volume; add 50 mg of activated pectinase, 30 mg of α-amylase and 6 mg of cellulase to each liter of apple pomace, stir well, and react for 12 hours; Saccharomyces cerevisiae with good activity is inoculated into the dregs, the dosage is 250 mg per liter of apple pomace, and the fermentation temperature is controlled at 20-28 degrees; during the alcoholic fermentation, the fermentation temperature and sugar content are monitored once every 8 hours; stirring every day in the early and late stages of fermentation 4 times, 5-10 minutes each time, stirring 6 times a day, 10-20 minutes each time during the vigorous fermentation period; when the sugar content is lower than 3g / L, the fermentation is over, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com