Molten slag content detection apparatus adopting solenoid

A technology of electromagnetic coils and detection devices, which is applied in the direction of material magnetic variables, etc., can solve the problems of shortening the life of the sensor, complex manufacturing process, and fragile insulating sheet, etc., and achieve the effects of shortening the manufacturing cycle, simplifying the manufacturing process, and prolonging the life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

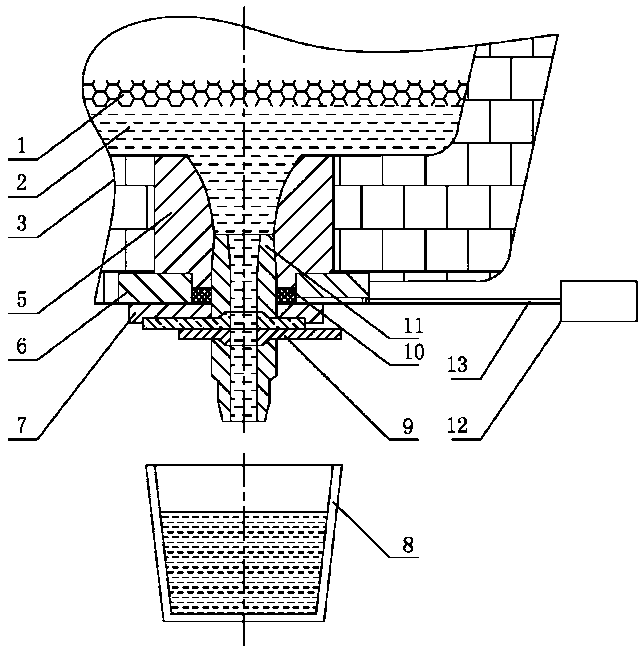

[0015] As a preferred embodiment, figure 1 The system diagram of the slag content detection device using the electromagnetic coil is given when the molten steel flows from the ladle to the tundish. There is an upper nozzle 11 at the bottom of the ladle 3 storing the molten steel 2, and the molten steel 2 flows into the tundish 8 through the upper nozzle 11 through the opening of the slide plate 9. The slag content detection device using electromagnetic coils includes a ring-shaped electromagnetic sensor 10 installed around the molten steel injection flow, a signal cable 13 and a signal processor 12 . In this embodiment, the annular electromagnetic sensor 10 is fixed around the molten steel injection and the upper nozzle 11, and its outer ring is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com