Method of disposing kitchen waste and recovering electric power with air cathode microbial fuel cell

An air cathode and fuel cell technology, applied in biochemical fuel cells and other directions, can solve problems such as low energy utilization rate and secondary pollution, and achieve the effects of low processing cost, high economic efficiency, and stable and good power generation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

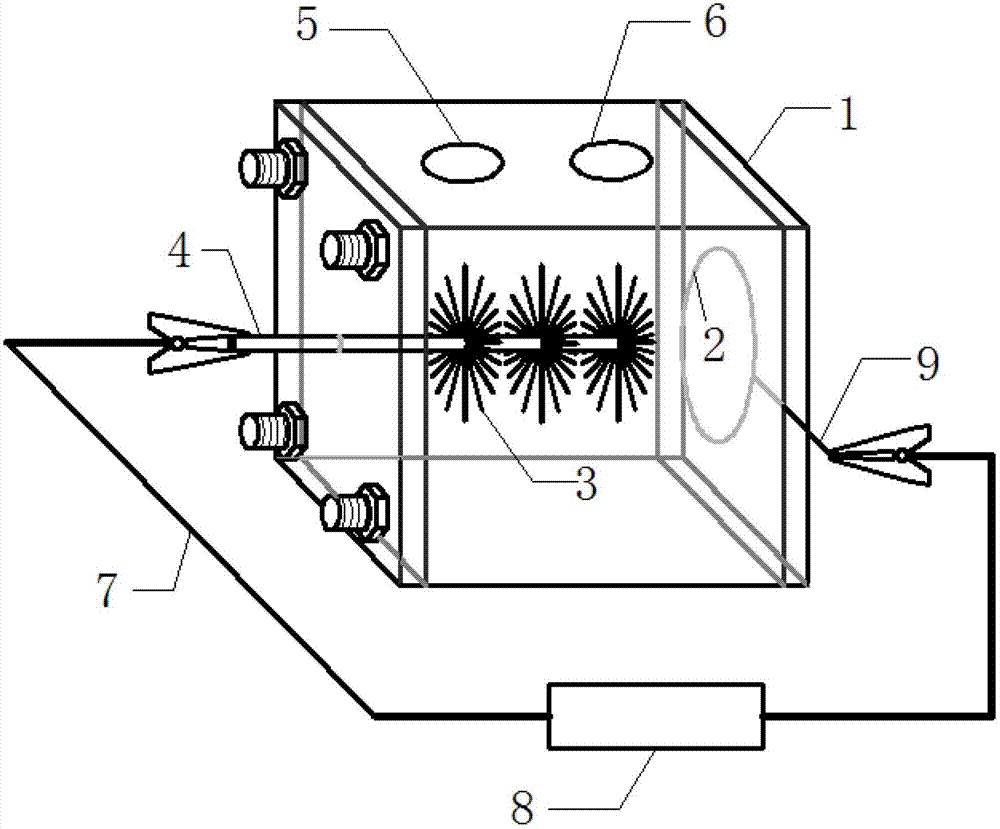

[0018] Specific implementation mode one: combined with figure 1 The specific implementation is further explained: the method for the air cathode microbial fuel cell in this embodiment to treat kitchen waste and recycle electric energy is implemented according to the following steps:

[0019] 1. Shake and mix the carbon powder and PTFE (polytetrafluoroethylene) with a volume concentration of 35% to 45%, apply it on one side of the carbon cloth, dry it at room temperature for 10 to 15 minutes, and place it in a muffle furnace. Heat treatment at ~400°C for 15-30 minutes, take it out and cool it at room temperature for 10-15 minutes to obtain the treated carbon cloth;

[0020] 2. Apply PTFE with a volume concentration of 55% to 65% on the side of the treated carbon cloth coated with PTFE, cool it at room temperature for 10 to 15 minutes, then place it in a muffle furnace, and heat it at 350 to 400°C Treat for 15-30 minutes, take out and cool at room temperature for 10-15 minutes;...

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that every 6cm in step three 2 The amount of raw materials used in the platinum-carbon catalyst coated on the carbon cloth cathode is 15 mg of platinum-carbon powder, 12.48 μL of deionized water, 100 μL of Nafion and 50 μL of isopropanol. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the diameter of the cross-section of the cylindrical carbon brush anode in step 4 is 2.5 cm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com