Automatic steel ball screening and packaging machine

An automatic screening and packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of waste of manpower, heavy workload, waste of raw materials, etc., and achieve the effect of saving the input of external power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with regard to specific accompanying drawings.

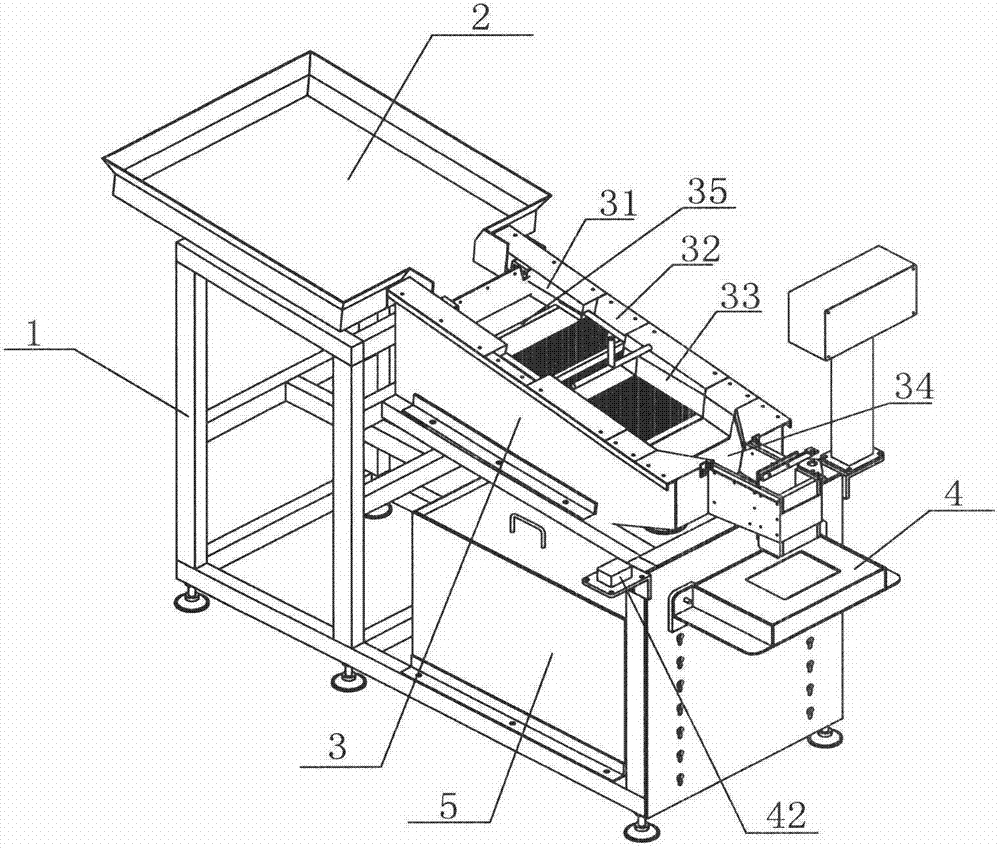

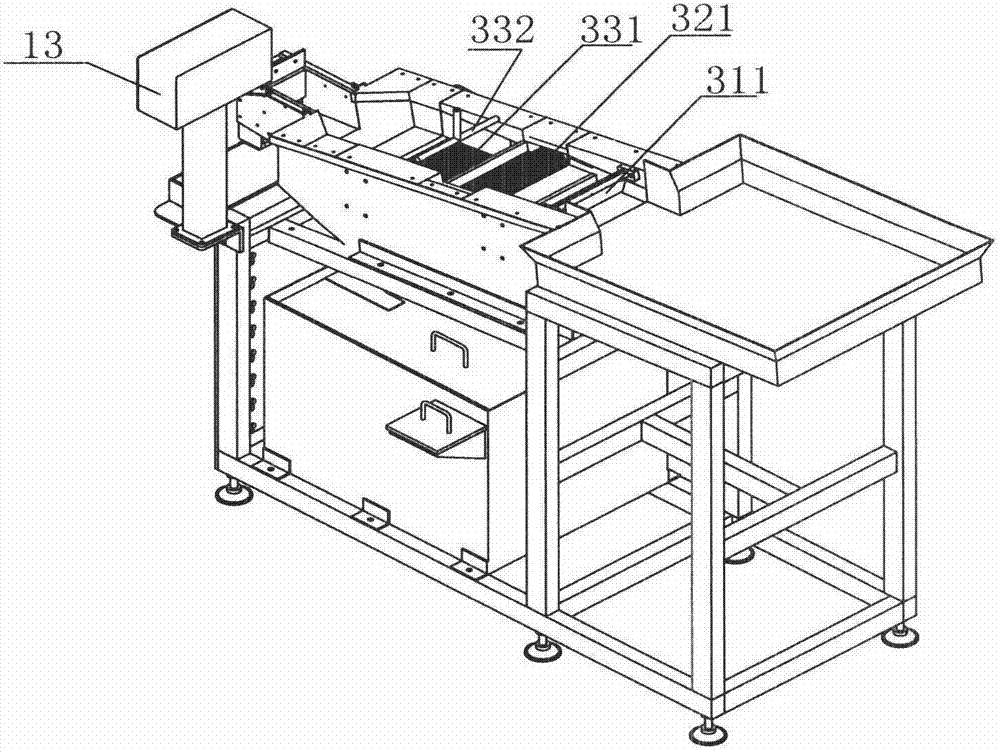

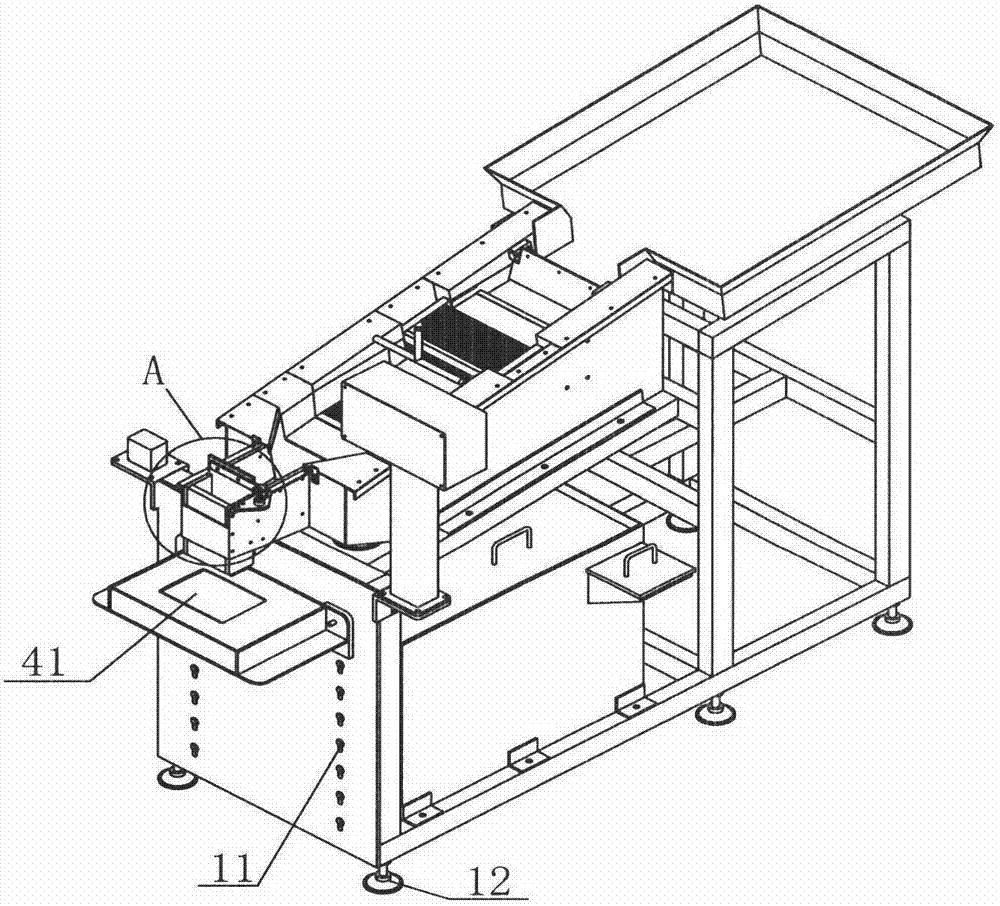

[0040] Such as Figure 1~3 A steel ball automatic screening and packaging machine shown includes a frame 1, a feeding box 2, a screening and filtering track 3, and a weighing platform 4, wherein:

[0041] The frame 1 is composed of two unit frames welded in a ladder shape, the unit frame is composed of a plurality of hollow square tubes welded, and a controller 13 is arranged at the right end of the frame, and the controller 13 controls the operation of the entire equipment;

[0042] The discharge box 2 is obliquely arranged on the left end of the frame, and the discharge box 2 forms an angle of 5° to 8° with the upper surface of the frame. The discharge port of the discharge box 2 is connected to the screen The feed port of the filter track 3 is docked;

[0043] The screening and filtering track 3 is arranged on the top of the frame inclined downward from the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com