Improved silver paste, application thereof and sintering method of chip and main body of power module

A modification and paste technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of poor bonding between Ag paste and the substrate, and achieve the effects of saving dosage, high working temperature and improving working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

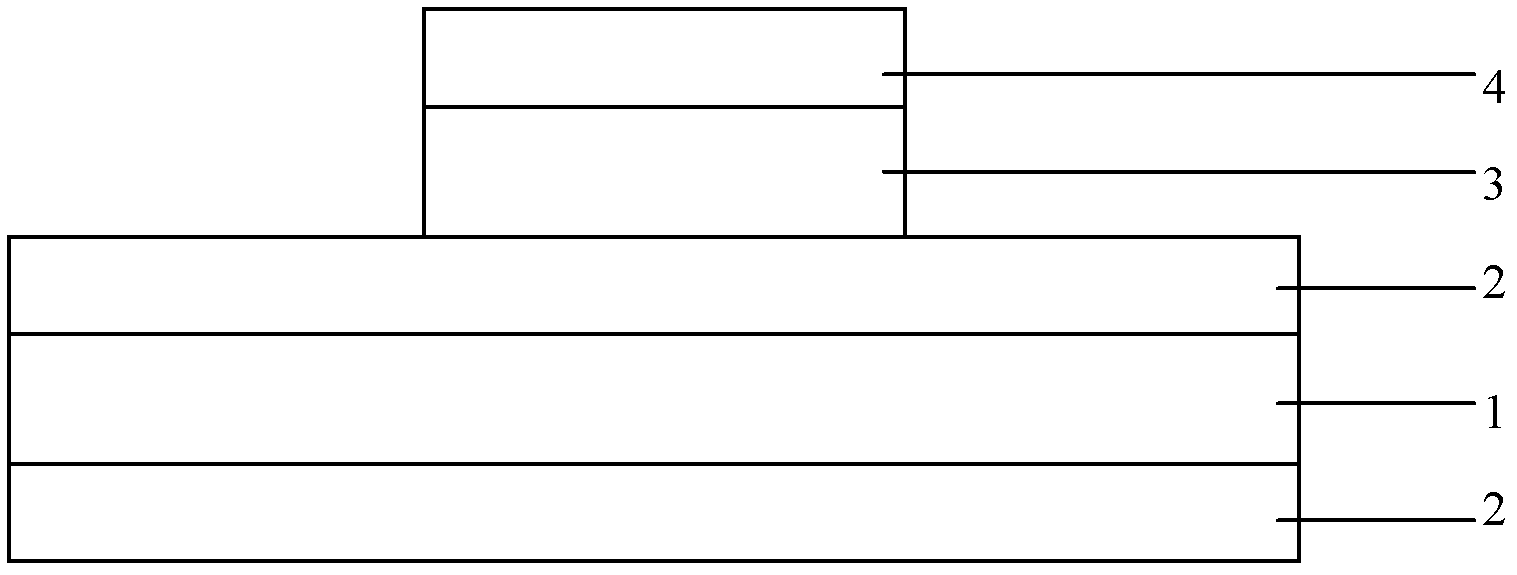

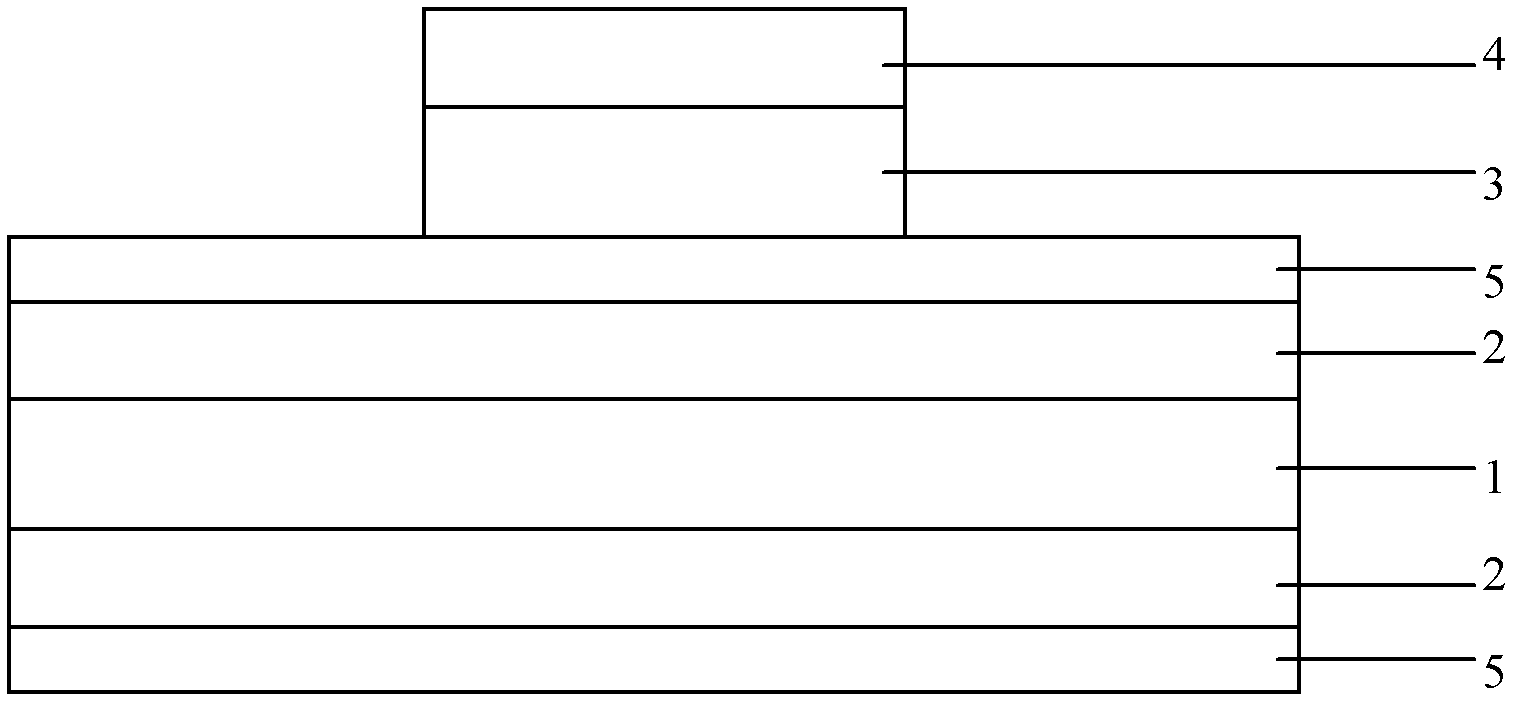

Method used

Image

Examples

Embodiment 1

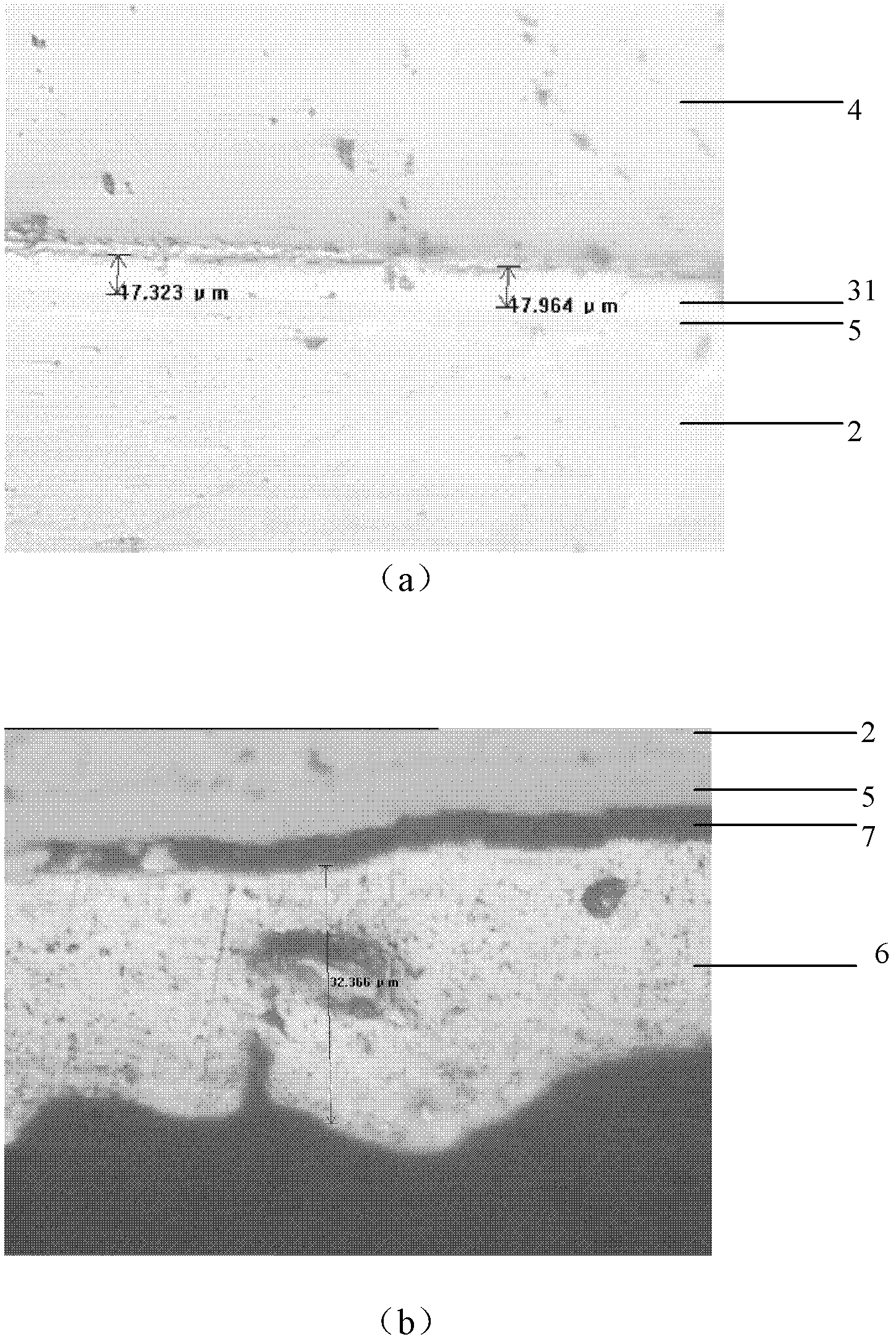

[0048] This embodiment is used to illustrate the sintering method for connecting a chip and a substrate in a power module using the modified Ag paste provided by the present invention.

[0049] Mix Ag metal powder, Sn metal powder and Sb metal powder with a particle size of 40-80nm and organic matter (α-terpineol, acetone, fish oil and polyvinyl butyral) uniformly to prepare a modified Ag paste. Based on the total amount of the modified Ag paste, the metal powder content was 78.5% by weight, and the organic matter content was 21.5% by weight. Based on the total amount of metal powder, the content of Ag metal powder is 84% by weight, the content of Sn metal powder is 10% by weight, and the content of Sb metal powder is 6% by weight; The content of oleyl alcohol was 23% by weight, the content of acetone was 70% by weight, the content of fish oil was 2.3% by weight, and the content of polyvinyl butyral was 4.7% by weight.

[0050] A layer of Ni is plated on the DBC substrate, ...

Embodiment 2

[0052] This embodiment is used to illustrate the sintering method for connecting a chip and a substrate in a power module using the modified Ag paste provided by the present invention.

[0053] Mix Ag metal powder, Sn metal powder and Cu metal powder with a particle size of 8-10 μm with organic matter (α-terpineol, methanol, fish oil and polyvinyl butyral) to make a modified Ag paste. Based on the total amount of modified Ag paste, the content of metal powder was 77% by weight, and the content of organic matter was 23% by weight. Based on the total amount of metal powder, the content of Ag metal powder is 94% by weight, the content of Sn metal powder is 5% by weight, and the content of Cu metal powder is 1% by weight; The content of oleyl alcohol was 17.4% by weight, the content of methanol was 78.2% by weight, the content of fish oil was 2.2% by weight, and the content of polyvinyl butyral was 2.2% by weight.

[0054] A layer of Ni is plated on the AMB substrate, and the mod...

Embodiment 3

[0056] This embodiment is used to illustrate the sintering method for connecting a chip and a substrate in a power module using the modified Ag paste provided by the present invention.

[0057] Mix Ag metal powder, Sn metal powder, Sb metal powder, Cu metal powder, Ni metal powder and Zn metal powder with a particle size of 25-30 μm with organic matter (α-terpineol, methanol, fish oil and polyvinyl butyral ) to mix evenly to make a modified Ag paste. Based on the total amount of modified Ag paste, the content of metal powder is 70% by weight, and the content of organic matter is 30% by weight. Based on the total amount of metal powder, the content of Ag metal powder is 77.98% by weight, the content of Sn metal powder is 12% by weight, the content of Sb metal powder is 8% by weight, the content of Cu metal powder is 2% by weight, Ni The content of metal powder is 0.01% by weight, and the content of Zn metal powder is 0.01% by weight; based on the total amount of organic matter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com