Preparation method of dialkyl phosphinate with high thermal stability

A technology of dialkyl phosphinate and alkyl phosphinate, applied in the field of preparation of dialkyl phosphinate, can solve problems such as poor thermal stability, achieve good thermal stability, high weight loss temperature, Solve the effect of easy fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

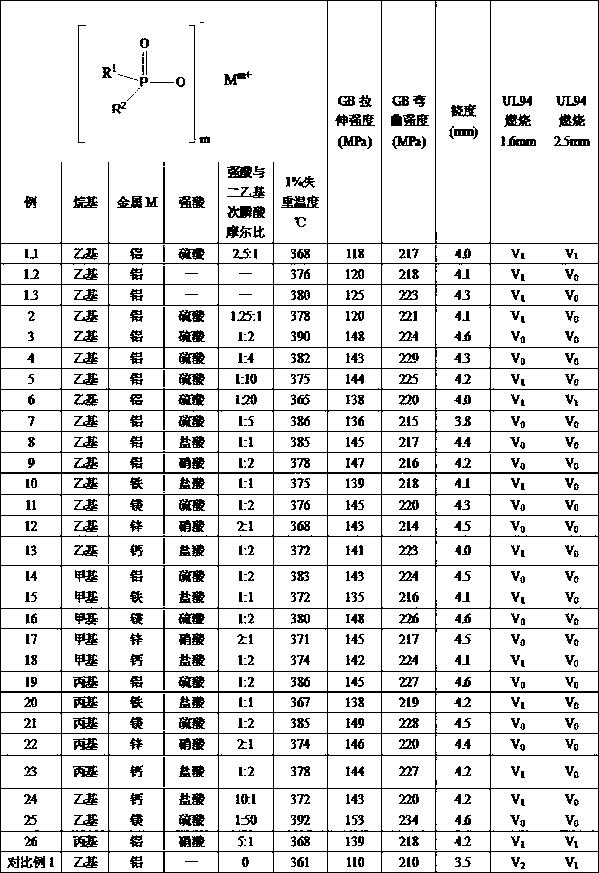

Examples

Embodiment 1

[0045] 1.1 Preparation of aluminum diethyl hypophosphite

[0046] Dilute 183g (1.2mol) 80% diethylphosphinic acid solution with water to 418.3g 35% diethylphosphinic acid solution, heat to 85°C, add 3mol 30% sulfuric acid solution to make the solution pH<1, Add 444g of a mixture of 30% by mass aluminum sulfate (M=666) and water dropwise within 45min, stir and react for 45min, a white solid is formed, cool and filter to obtain 129g of filter cake, the water content of the filter cake is 40%, and 1713g of filtrate is obtained , The filtrate is recycled. The precipitate was washed with 3L of deionized water, and dried at 200°C for 10 hours to obtain 78.0 g of aluminum diethylphosphinate, with a yield of 50.0% and a moisture content of 0.6%.

[0047] Tap density (g / L): 602; TG: 1% weight loss temperature 368°C, 5% weight loss temperature 423°C.

[0048] IR: 779cm -1 , 1077 cm -1 , 1152cm -1 , 2881 cm -1 , 2959 cm -1

[0049] 1.2 Example 1.1 Filtrate recovery and prepar...

Embodiment 2

[0058] Prepare aluminum diethylphosphinate as in Example 1, heat 610g (1.5mol) of 30% diethylphosphinic acid solution to 70°C, add 1.875mol of 99% sulfuric acid solution to make the solution pH<1, within 30min Add dropwise 333g of a mixture of 50% by mass aluminum sulfate (M=666) and water, stir for 50 minutes to generate a white solid, cool, filter, and recycle the filtrate, wash the precipitate with 4L of deionized water, and dry at 200°C for 10 hours , to obtain 114.3 g of aluminum diethylphosphinate, with a yield of 58.6% and a moisture content of 0.4%.

[0059] Tap density (g / L): 601; TG: 1% weight loss temperature 378°C, 5% weight loss temperature 428°C.

Embodiment 3

[0061] Prepare aluminum diethylphosphinate as in Example 1, heat 732g (0.6mol) of 10% diethylphosphinic acid solution to 100°C, add 0.3mol of 60% sulfuric acid solution to make the solution pH<1, within 30min Add dropwise 333g of a mixture of 20% by mass aluminum sulfate (M=666) and water, stir for 0.1h to generate a white solid, cool, filter, and recycle the filtrate, wash the precipitate with 3L of deionized water, and dry at 200°C After 10 hours, 48.4 g of aluminum diethylphosphinate was obtained, with a yield of 62.0% and a moisture content of 0.3%.

[0062] All the other steps are the same as 1.2 and 1.3 in Example 1, and the final product total yield is 96.3%.

[0063] Tap density (g / L): 660; TG: 1% weight loss temperature 390°C, 5% weight loss temperature 440°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com