A method for improving the secondary processing stability of polyhydroxy acid

A technology for secondary processing and stability, applied in the field of improving the stability of secondary processing of polyhydroxy acid, can solve the problems of the impact of material performance, mechanical strength, gas barrier performance decline, accelerated degradation of polyhydroxy acid, etc., to achieve high mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

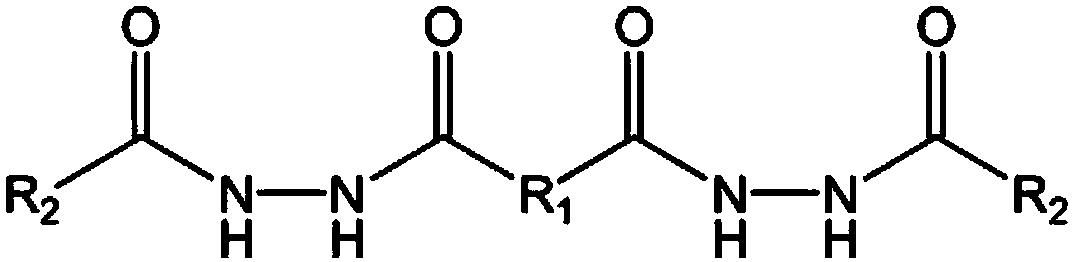

Method used

Image

Examples

Embodiment 1

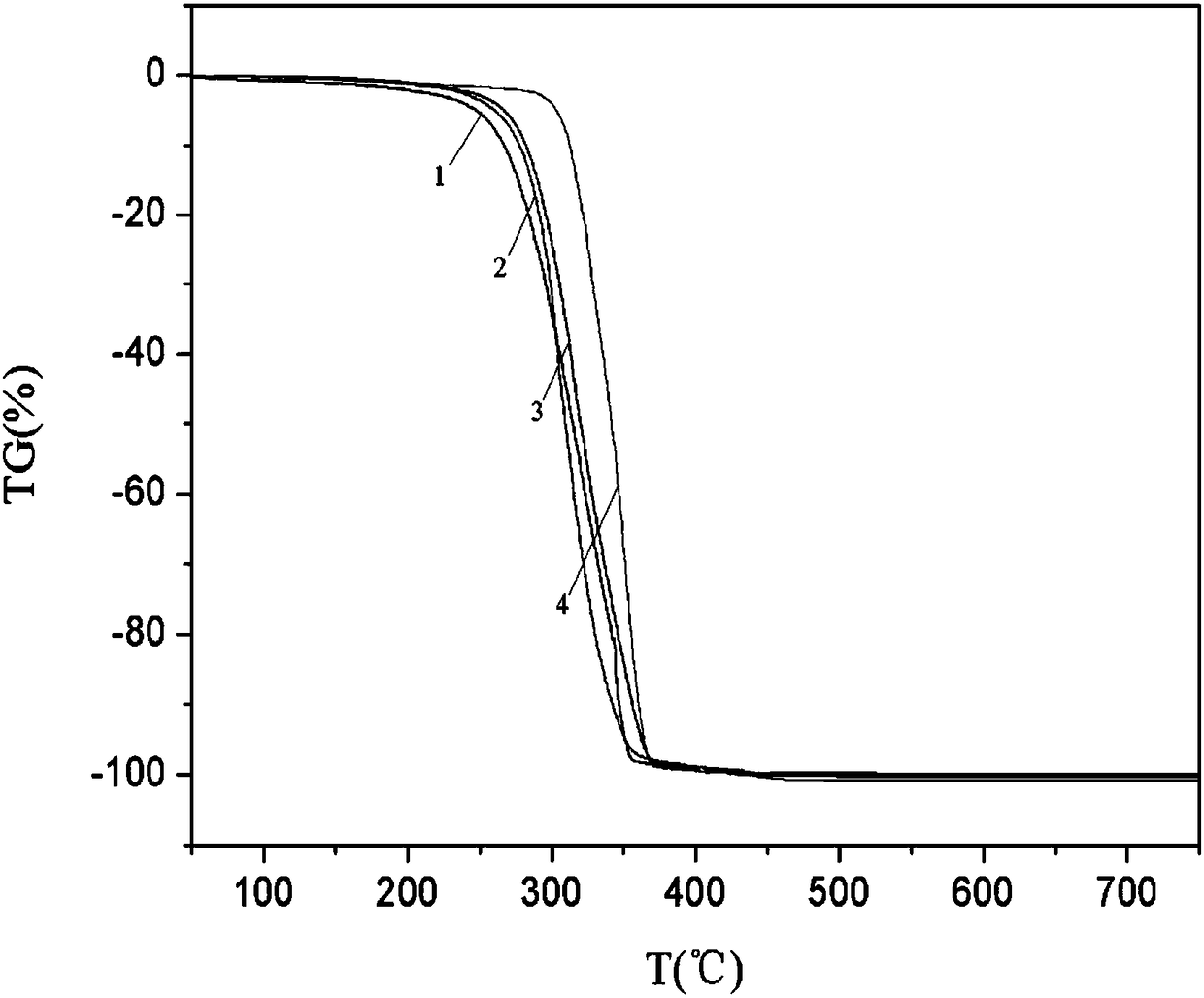

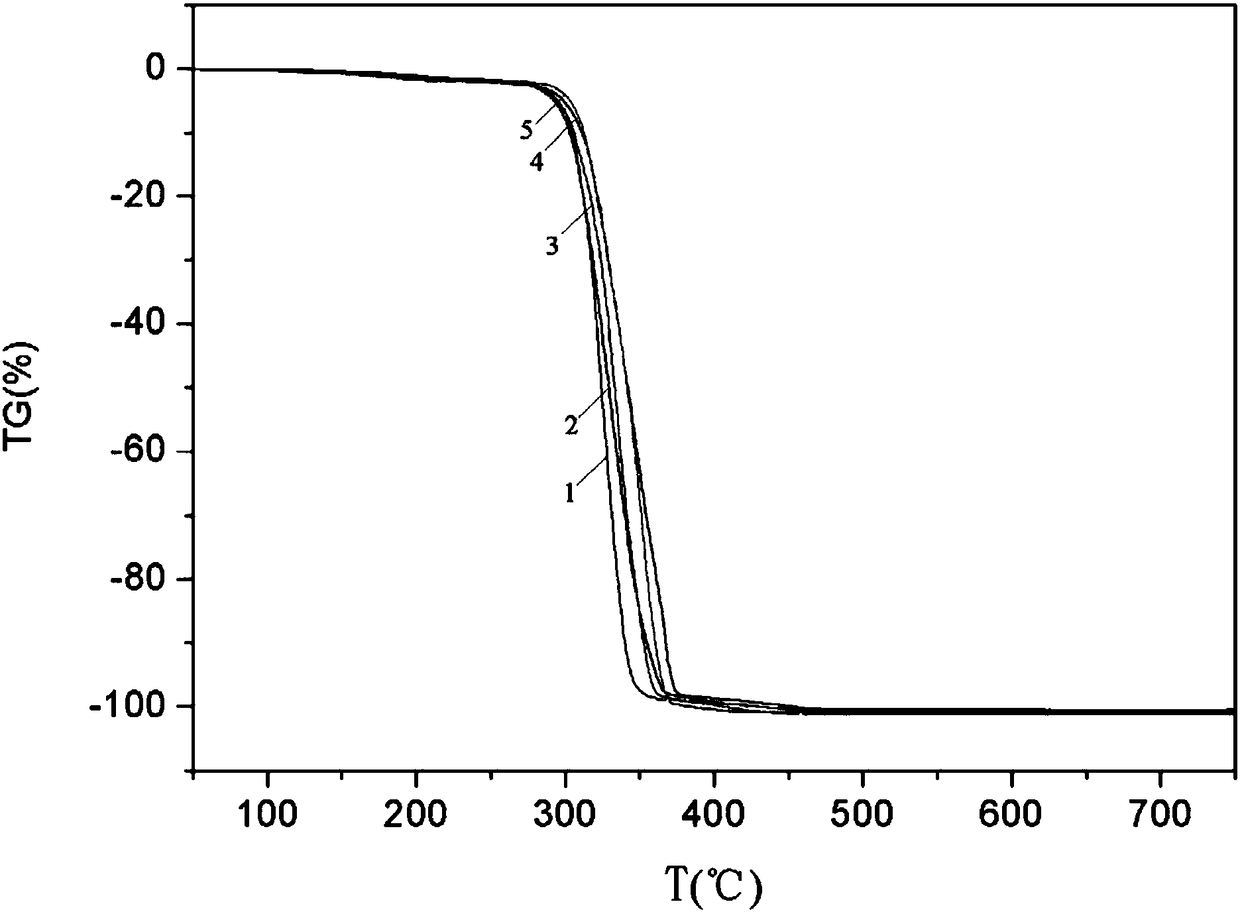

[0026] Take 10g of polyglycolic acid with a molecular weight of 200,000, add dodecanedioic acid dibenzohydrazide according to the addition amount of 0.011mmol / g, mix the two evenly with a pulverizer, and then add them to the German Hacker MiniLab through a feeding funnel at a constant speed In the twin-screw machine, feeding rate: 40g / h; screw speed: 20rpm; twin-screw temperature: 230°C; cooling after extrusion.

Embodiment 2

[0028] Take 10g of the same polyglycolic acid as in Example 1, add dodecanedioic acid di-n-heptanoylhydrazide according to the addition amount of 0.011mmol / g, mix the two evenly with a pulverizer, and then add them to Hacker, Germany at a constant speed through the addition funnel. In the MiniLab twin-screw machine, the processing parameters are the same as in Example 1.

Embodiment 3

[0030] Take 10 g of the same polyglycolic acid as in Example 1, add adipate disalicyylhydrazide according to the addition amount of 0.011 mmol / g, mix the two evenly with a pulverizer, and then add them to the German Hacker MiniLab twin-screw machine through a feeding funnel at a constant speed Among them, processing parameter is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com