Method for improving thermal stability of polycarbonate

A technology of polycarbonate and thermal stability, applied in the field of environmentally friendly polymer materials, can solve the problems of poor thermal stability, complicated operation, limited application and development, etc., and achieve the effect of improving thermal stability and high weight loss temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation of the polycarbonate PECHC: first place the dried 300mL autoclave in an ice-water bath to cool, then add the freshly prepared catalyst into the autoclave, and after the temperature in the autoclave drops below 10°C, then Add 20mL CHO and 5mLEO respectively. Tighten the autoclave and feed CO 2 The air in the kettle was discharged, and then the autoclave was heated in an oil bath, adjusted to an appropriate pressure, and magnetic stirring was continued at a speed of 1000 rpm. After reacting for a certain period of time, the autoclave was taken out, cooled in an ice-water bath, and the pressure was slowly released to normal pressure. Anhydrous methanol was added to terminate the reaction, and then the product was dissolved with dichloromethane and precipitated with anhydrous methanol. The resulting polymer was vacuum dried at 50°C to constant weight.

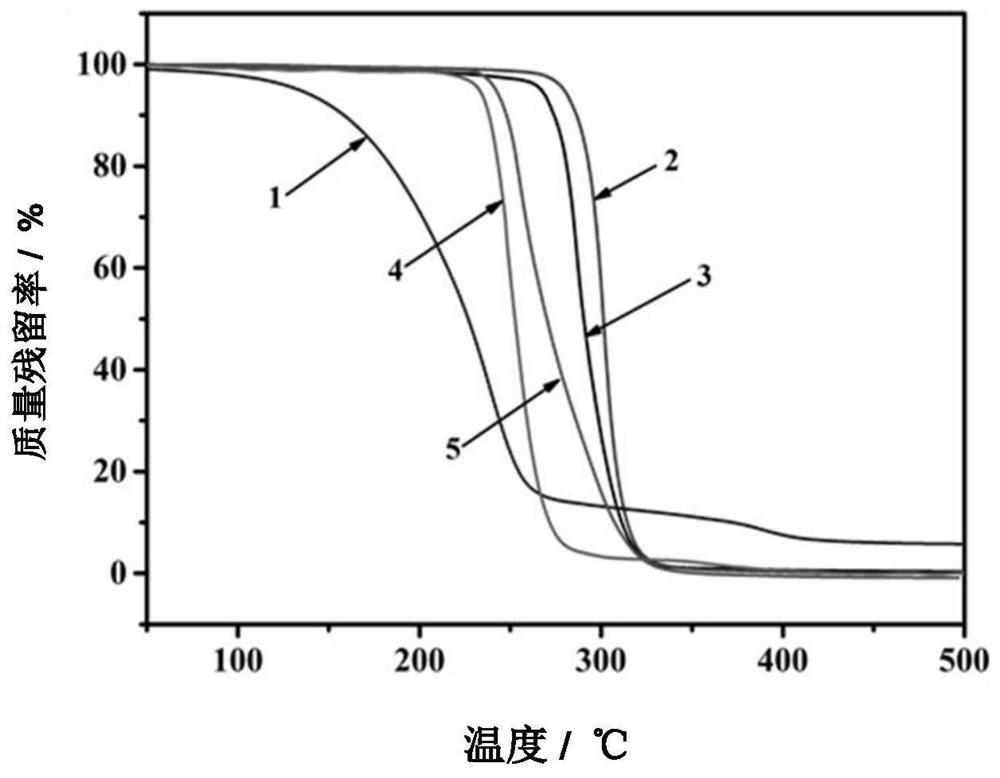

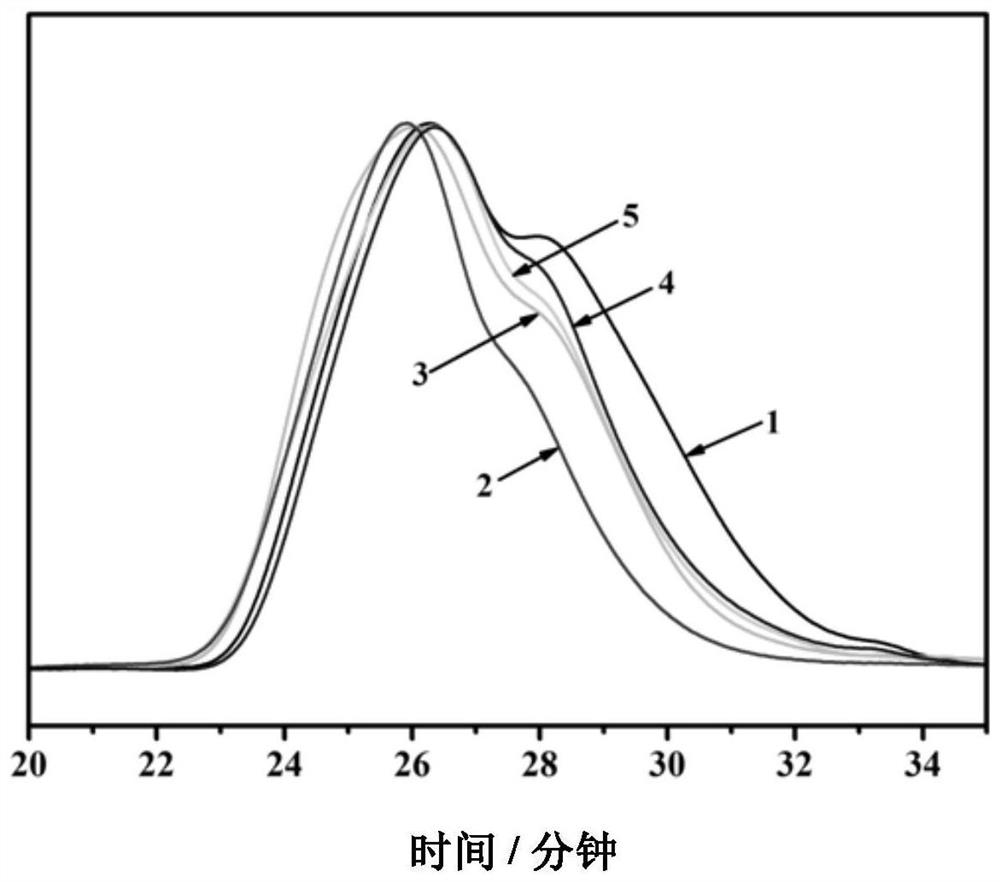

[0045] Said purification method: After the newly prepared poly(ethylene cyclohexene carbonate) is compl...

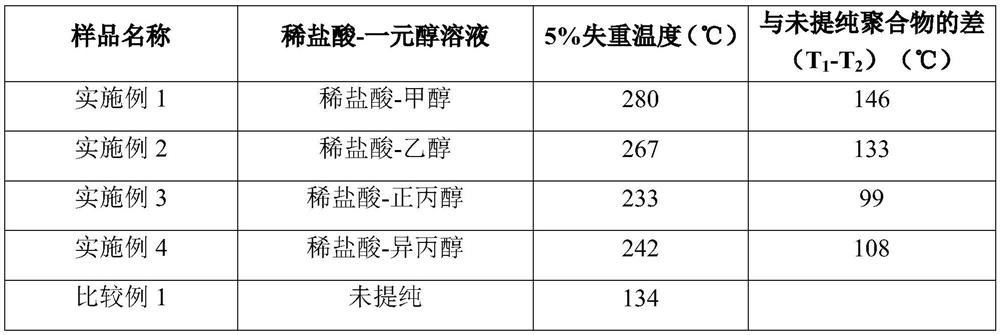

Embodiment 1

[0051] Take 10g of PECHC, dissolve it completely with dichloromethane, and slowly pour it into the 5% dilute hydrochloric acid-methanol solution just prepared. The volume ratio of dichloromethane to dilute hydrochloric acid-methanol solution is 1:5. And keep stirring at a constant speed in the same direction. After the PECHC precipitation is complete, use a circulating water pump to perform suction filtration to remove the filtrate, and dry the obtained PECHC for the determination of the thermogravimetric reduction temperature.

Embodiment 2

[0053] Take 10g of the same PECHC as in Example 1, dissolve it completely in dichloromethane, and slowly pour it into the newly prepared 5% dilute hydrochloric acid-ethanol solution, the volume ratio of dichloromethane to dilute hydrochloric acid-ethanol solution is 1:5 , during the pouring process and keep stirring in the same direction at a constant speed. After the PECHC precipitation is complete, use a circulating water pump to perform suction filtration to remove the filtrate, and dry the obtained PECHC for the determination of the thermogravimetric reduction temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com