Epoxy modified organic silicon resin adhesive and preparation method thereof

A technology of resin adhesive and epoxy modification, which is applied in epoxy resin coatings, coatings, polyurea/polyurethane coatings, etc., and can solve problems such as poor adhesion, unsatisfactory use requirements, and unreasonable formula ratios. , to achieve the effect of good adhesion, good adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

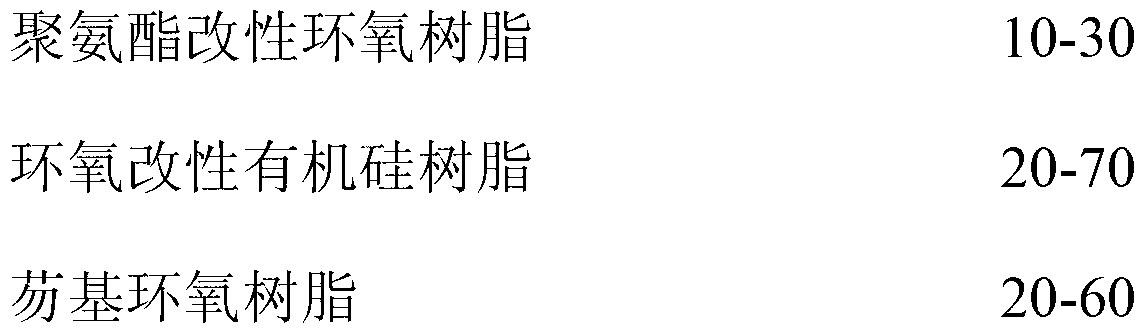

[0030] The epoxy modified silicone resin adhesive of the present invention consists of the following components in parts by weight:

[0031]

[0032]

[0033] Preparation:

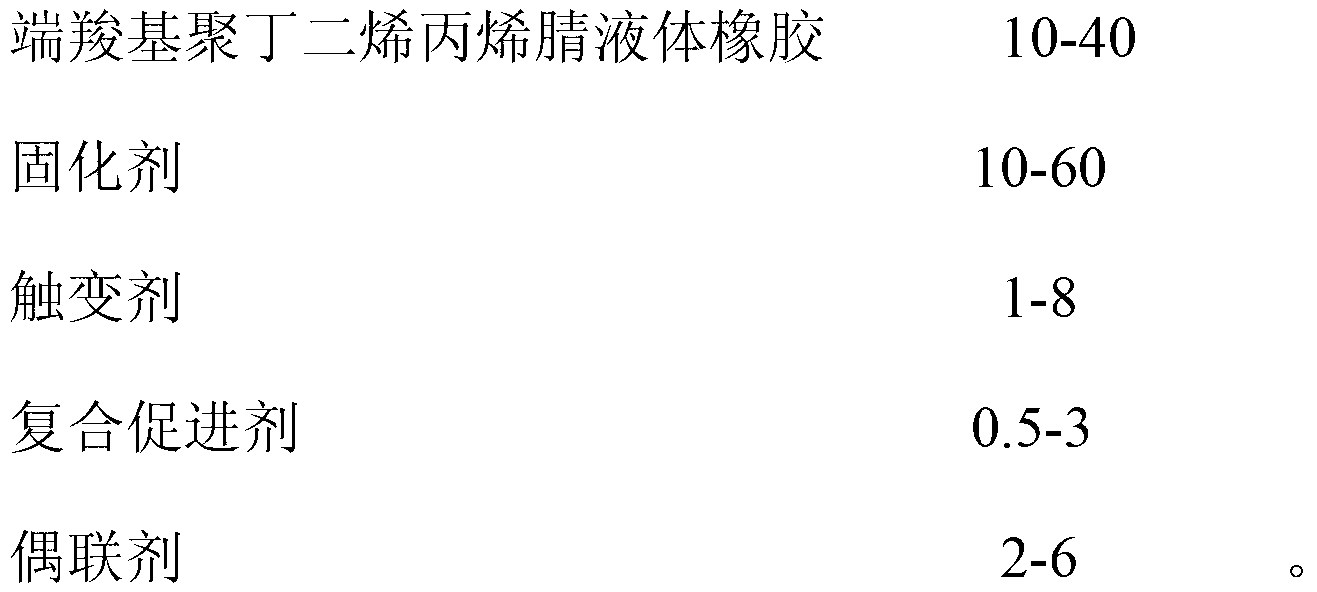

[0034] A, preparation of polyurethane modified epoxy resin

[0035] Heat 15 parts by weight of polyester polyol to 100°C for reflux dehydration, cool down to 40°C, add 4 parts by weight of diphenylmethane diisocyanate, heat to 65°C, react for 1 hour, cool to room temperature, add 0.5 parts by weight of 2 , 3 butanediol and 1 weight part of trimethylolpropane were stirred uniformly to obtain a polyurethane prepolymer, and 100 parts by weight of epoxy resin was added to the polyurethane prepolymer to react for 1 hour to obtain a polyurethane modified epoxy resin;

[0036] B. Preparation of epoxy modified silicone resin:

[0037] In the reaction kettle, add 80 parts by weight of hydroxyl-terminated polydimethylsiloxane, 30 parts by weight of bisphenol A type epoxy resin and 3 parts by weight of dibuty...

Embodiment 2

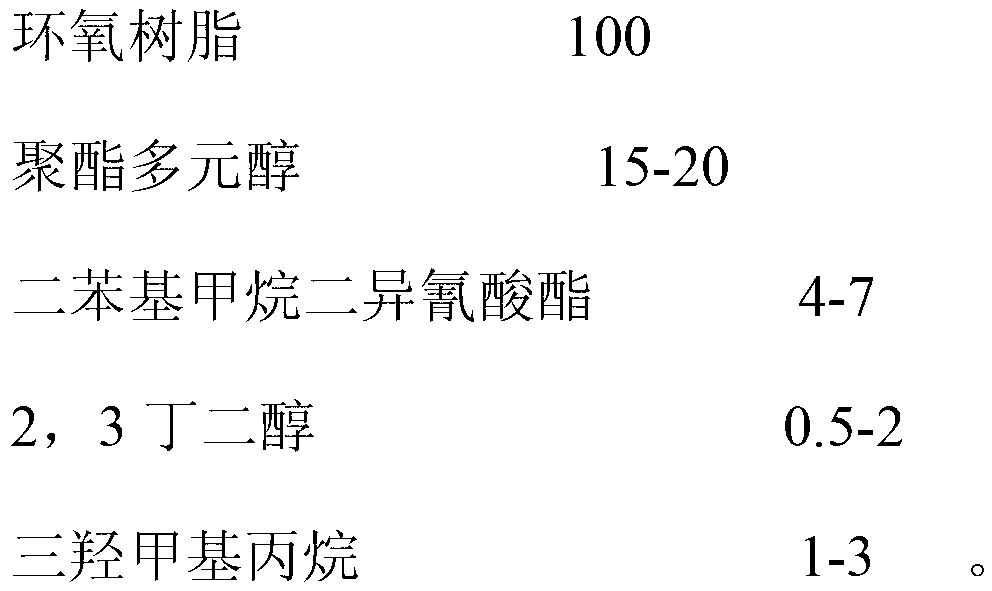

[0043] The epoxy modified silicone resin adhesive of the present invention consists of the following components in parts by weight:

[0044]

[0045] Preparation:

[0046] A, preparation of polyurethane modified epoxy resin

[0047] Heat 20 parts by weight of polyester polyol to 120°C for reflux dehydration, cool down to 60°C, add 7 parts by weight of diphenylmethane diisocyanate, heat to 80°C, react for 3 hours, cool to room temperature, add 2 parts by weight of 2 , 3 butanediol and 3 parts by weight of trimethylolpropane were stirred uniformly to obtain a polyurethane prepolymer, and 100 parts by weight of epoxy resin was added to the polyurethane prepolymer to react for 3 hours to obtain a polyurethane modified epoxy resin;

[0048] B. Preparation of epoxy modified silicone resin:

[0049] In the reaction kettle, add 80 parts by weight of hydroxyl-terminated polydimethylsiloxane, 30 parts by weight of bisphenol A type epoxy resin and 3 parts by weight of dibutyltin dil...

Embodiment 3

[0055] The epoxy modified silicone resin adhesive of the present invention consists of the following components in parts by weight:

[0056]

[0057] Preparation:

[0058] A, preparation of polyurethane modified epoxy resin

[0059] Heat 16 parts by weight of polyester polyol to 110°C for reflux dehydration, cool down to 50°C, add 5 parts by weight of diphenylmethane diisocyanate, heat to 70°C, react for 2 hours, cool to room temperature, add 1 part by weight of 2 , 3 butanediol and 2 parts by weight of trimethylolpropane were stirred uniformly to obtain a polyurethane prepolymer, and 100 parts by weight of epoxy resin was added to the polyurethane prepolymer to react for 2 hours to obtain a polyurethane modified epoxy resin;

[0060] B. Preparation of epoxy modified silicone resin:

[0061] In the reaction kettle, add 80 parts by weight of hydroxyl-terminated polydimethylsiloxane, 30 parts by weight of bisphenol A type epoxy resin and 3 parts by weight of dibutyltin dilaur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com