Road deicing and snow cleaning car

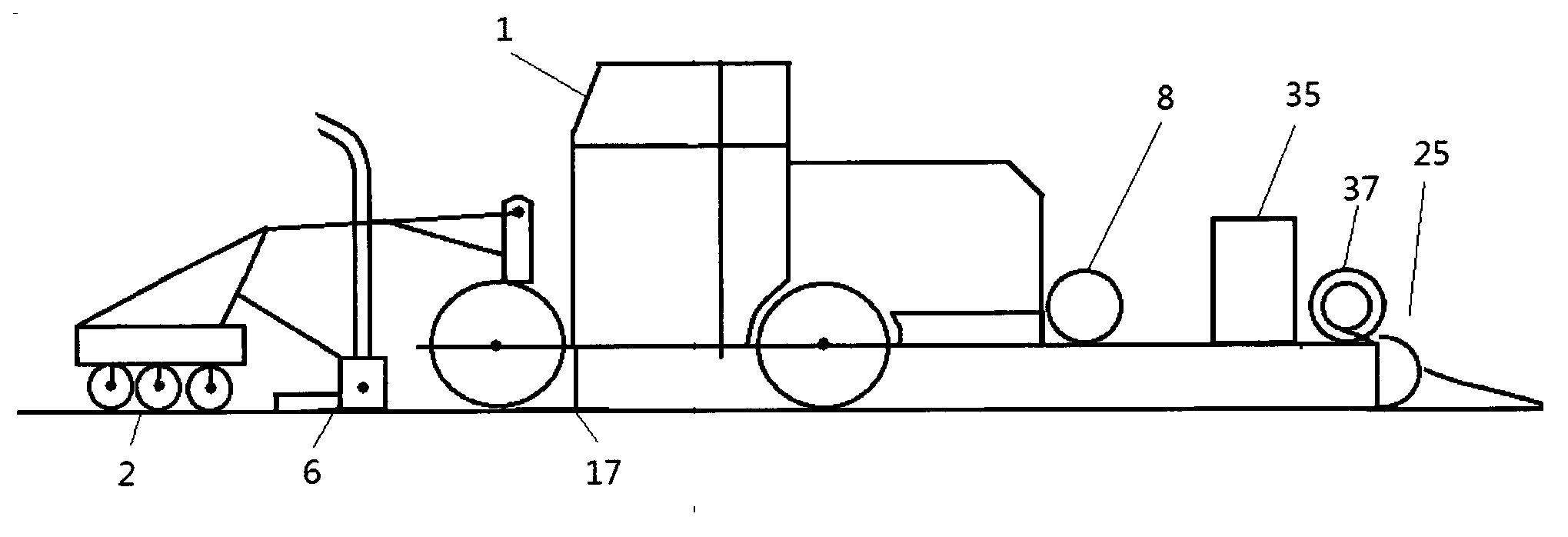

A snow sweeper and road technology, applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of occupying road surface area, waste of resources, limited width of dozers, etc. The effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

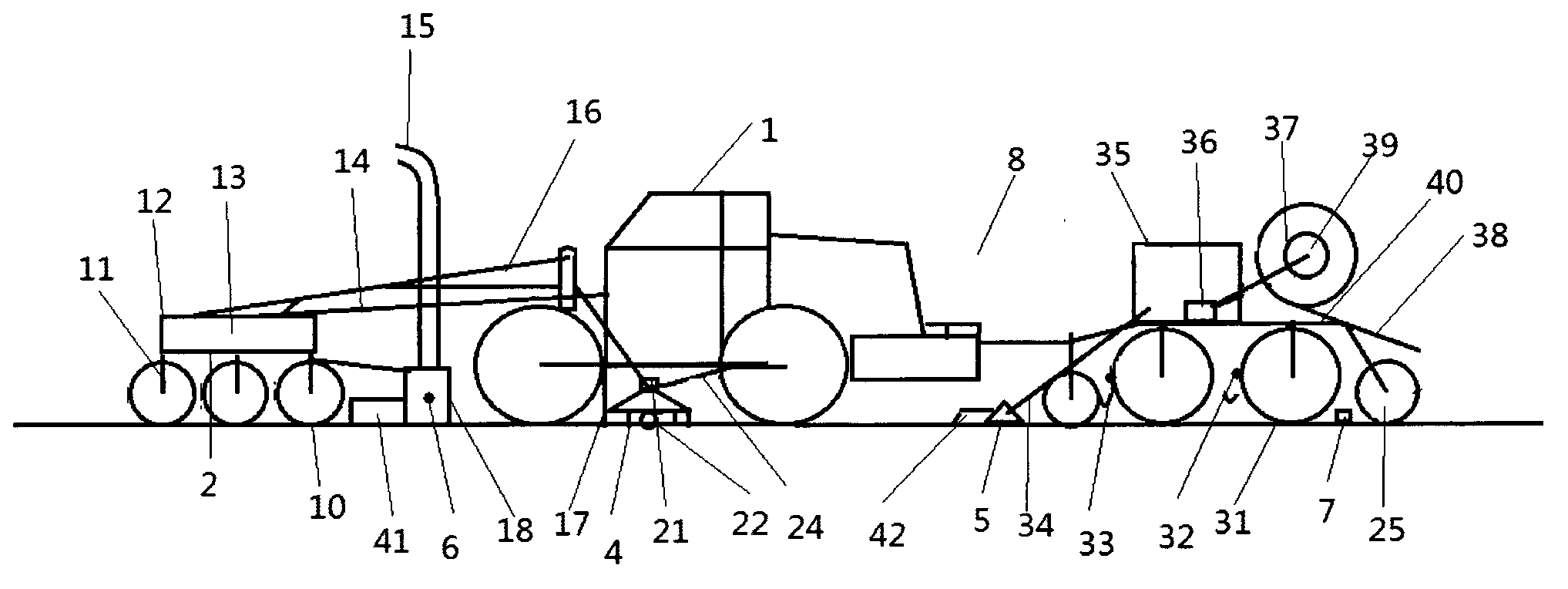

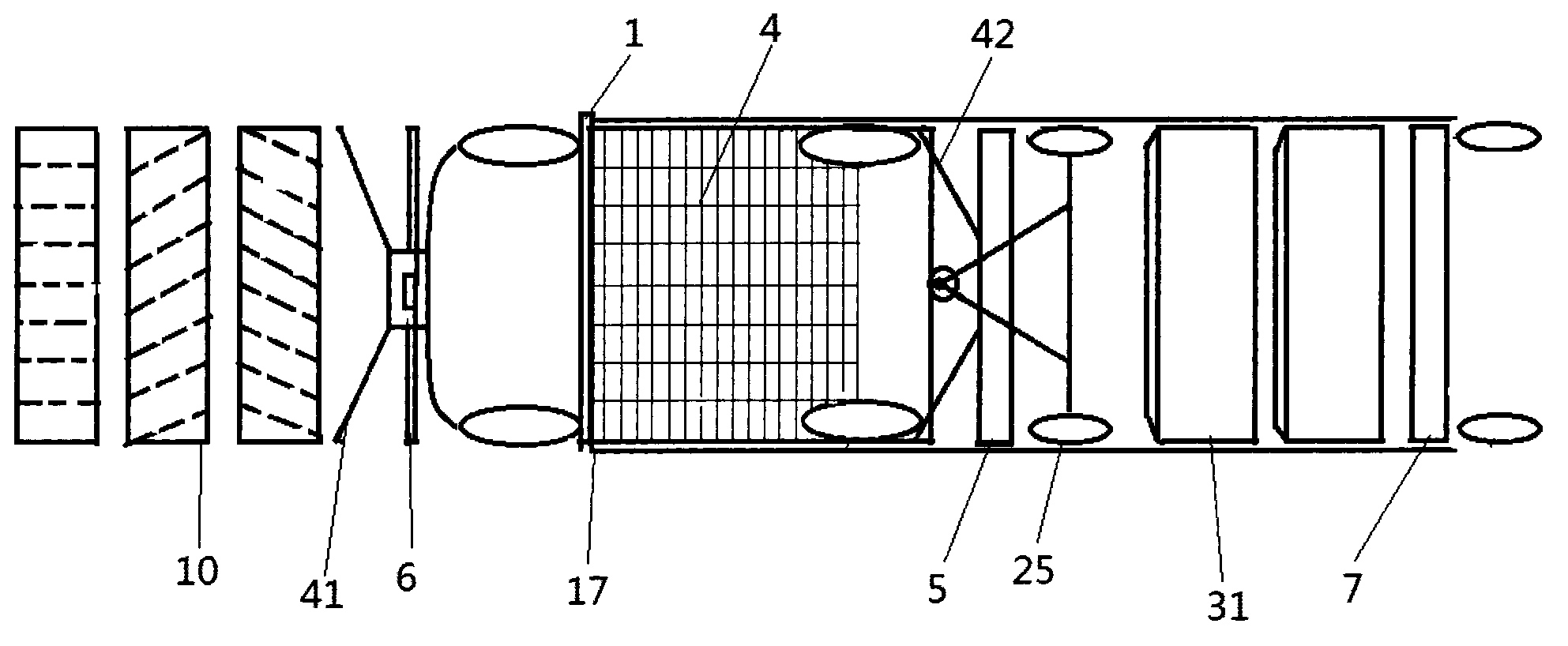

Embodiment 1

[0037] Embodiment one: after the present invention enters the operation area, put the ice crushing system 2 suspended by the curved beam 16 at the front end of the loader 1 to the ground (such as figure 2 As shown), first load counterweights (soil, stones and other heavy objects) into the counterweight box 13 according to the thickness of the icing on the road surface, or use the hydraulic device of the loader to forcefully crush the ice crushing system 2. At this time, the linear cutter plum blossom wheel 10. Under heavy pressure, do point-like linear cutting to the ice layer, followed by the left inclined line plum blossom wheel 10 cutters for left inclined point-shaped cutting, and finally the right inclined line plum blossom wheel 10 cutters for right inclined point-shaped cutting, This moment, most of the ice and snow attached to the road surface have been cut off and shredded, and the snow scraper 41 (such as image 3 Shown) after scraping into blower fan 6 inlets, blow ...

Embodiment 2

[0038]Embodiment 2: If the ice crushing system 2 does not completely clean up the ice and snow, the remaining ice and snow enter the curtain 17 (the temperature in the curtain is relatively high at this time) and blow out the hot air (hot air) through the heating wire 23 in the ice melting device 4. Taken from the engine radiator on the loader 1, the blower 21 blows through the heating wire 23 for secondary heating), blows to the ice and snow, melts into water completely, and then enters the suction cup 5 through the water scraper 42 and then sends it into the water tank through the suction pipe 34 35.

Embodiment 3

[0039] Embodiment three; if the melted snow water is not sucked up by the sucker 5, the two rows of sticking rollers 31 will suck the water, then squeeze it through the pressing roller 32, enter the water tank 33, and return to the suction pipe 34 to suck the water into the water tank 35. Sometimes the road surface will be wet and then dry through the high-temperature drying drum 7 (drying drum airflow also comes from the loader 1 radiator, and has reached a high temperature through the electric heating device).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com