Whisker enhanced photosensitive resin aero-elastic high-speed wind tunnel test model

A photosensitive resin and high-speed wind tunnel technology, applied in teaching models, educational tools, instruments, etc., can solve the problems of difficult elimination of thermal stress and thermal strain, large error of dynamic response index, low degree of process automation, etc. Machining accuracy and high surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

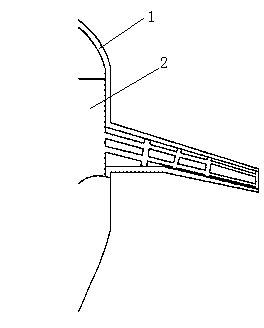

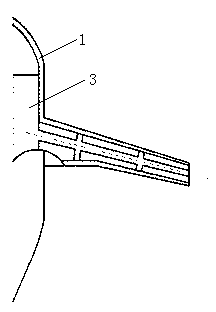

[0025] like figure 1 and figure 2 Shown: the photosensitive resin aeroelastic high-speed wind tunnel test model that the whisker of the present invention strengthens, comprises skeleton and the skin that is outsourced on the skeleton, and wherein the material of skin is photosensitive resin, and photosensitive resin is a kind of polymer, in Whiskers are added to the photosensitive resin, and the content of the whiskers is 6% of the mass of the photosensitive resin. After mixing the photosensitive resin and whiskers evenly, use the current mature light-curing molding process to make a skin or a skeleton, and then fix the skin on the skeleton to make an aeroelastic wind tunnel test model. Among the above-mentioned materials, the present invention makes full use of the characteristics of whiskers, has high strength and high modulus, and has a slender structure. After being added to the photosensitive resin, it can be uniformly dispersed and play the role of a skeleton to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com