Insulated gate bipolar transistor (IGBT) and producing method thereof

The technology of a bipolar transistor and a manufacturing method is applied in the manufacture of insulated gate bipolar transistors and the field of insulated gate bipolar transistors, which can solve the problems of high base resistance, large Joule heat, large on-state voltage, etc., so as to reduce conduction Resistance, the effect of reducing resistance and Joule heating, increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

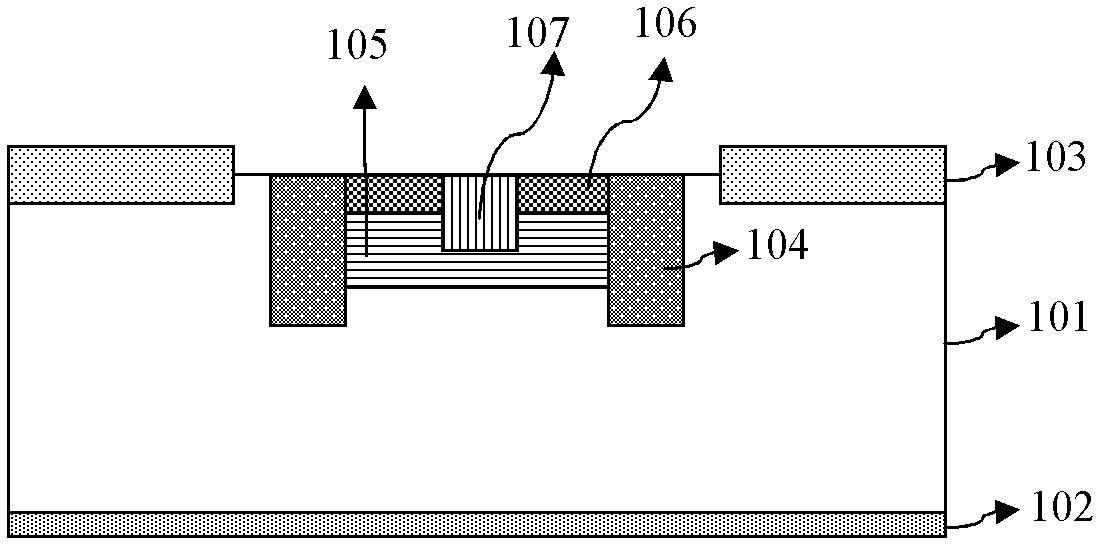

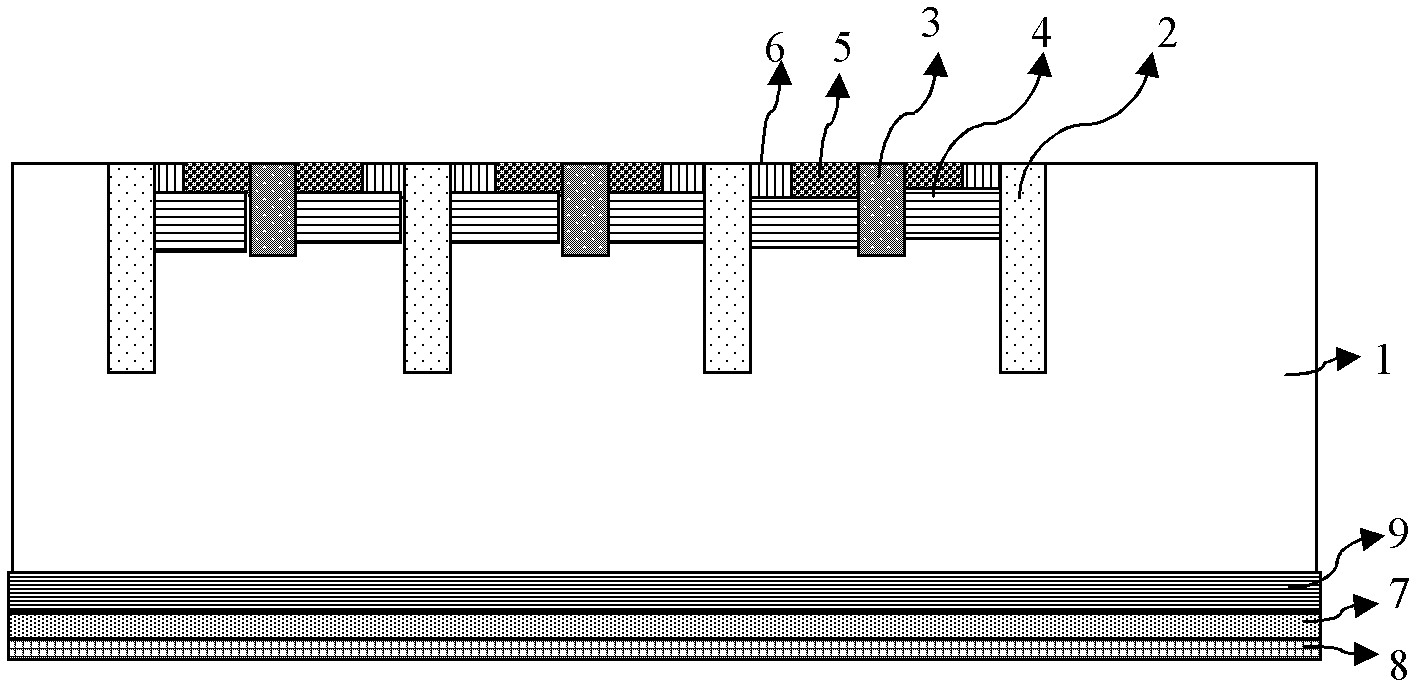

[0039] Such as figure 2 Shown is a schematic diagram of the structure of the IGBT of the embodiment of the present invention; the insulated gate bipolar transistor of the embodiment of the present invention includes:

[0040] The collector region 7 is composed of a P-type layer formed at the bottom of the silicon substrate, and the back metal 8 is formed from the back of the silicon substrate to lead out the collector.

[0041] The field stop layer 9 is composed of an N-type injection layer formed on the bottom of the silicon substrate, and the N-type injection layer is located on the upper part of the collector region and is in contact with the collector region.

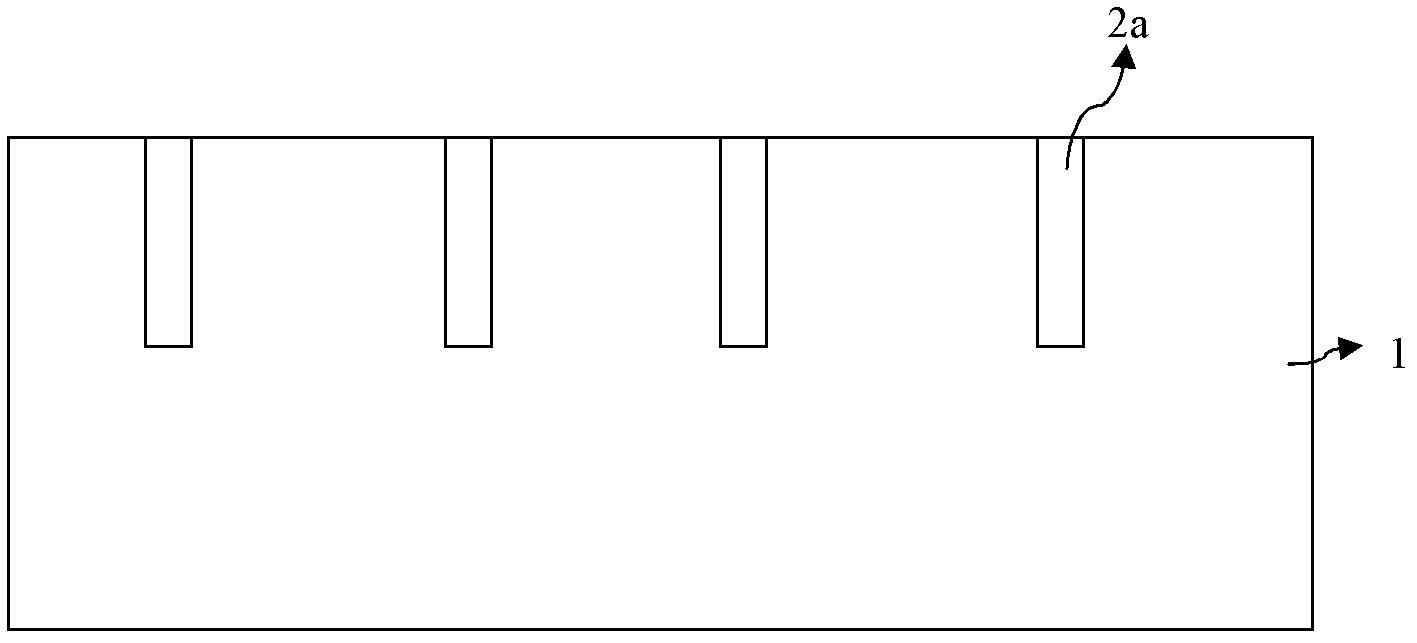

[0042] The drift region 1 is composed of a first N-type layer formed in the silicon substrate, the first N-type layer is located on the N-type implanted layer, and the doping concentration of the N-type implanted layer is greater than that of the Doping concentration of the first N-type layer. The thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com