Fast recovery epitaxial diode (FRED) and preparation method thereof

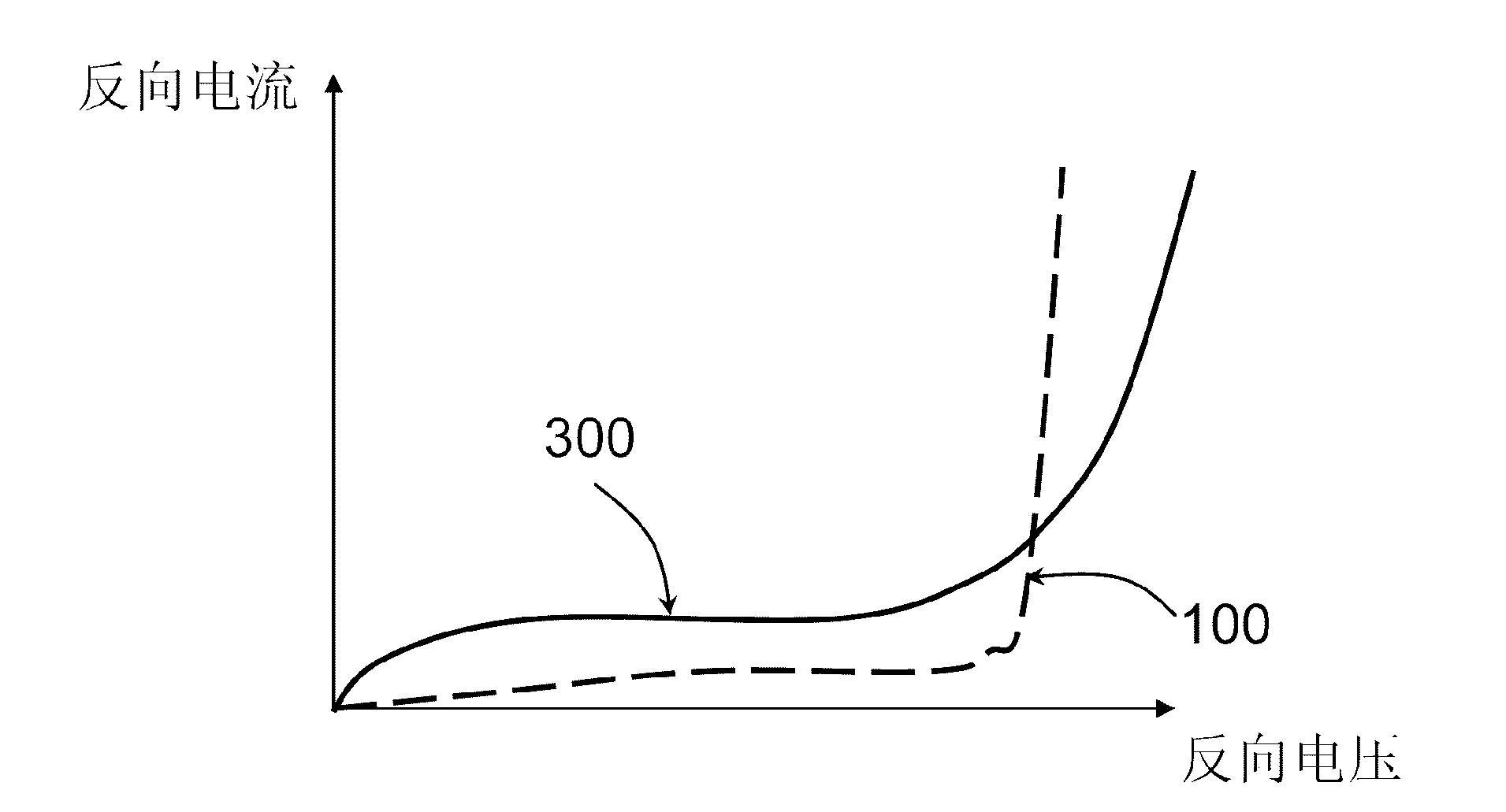

A fast recovery, diode technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of hard reverse breakdown characteristics, low avalanche resistance, poor anti-avalanche performance, etc., to achieve redistribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069]Fig. 6 is a schematic flow diagram of the method for preparing the FRED of the embodiment shown in Fig. 3 according to an embodiment of the present invention; Fig. 7 to Fig. 13 are schematic diagrams of structural changes corresponding to the method flow shown in Fig. 6 . The preparation process of the FRED 30 of the present invention will be described in detail below with reference to FIGS. 6 to 13 .

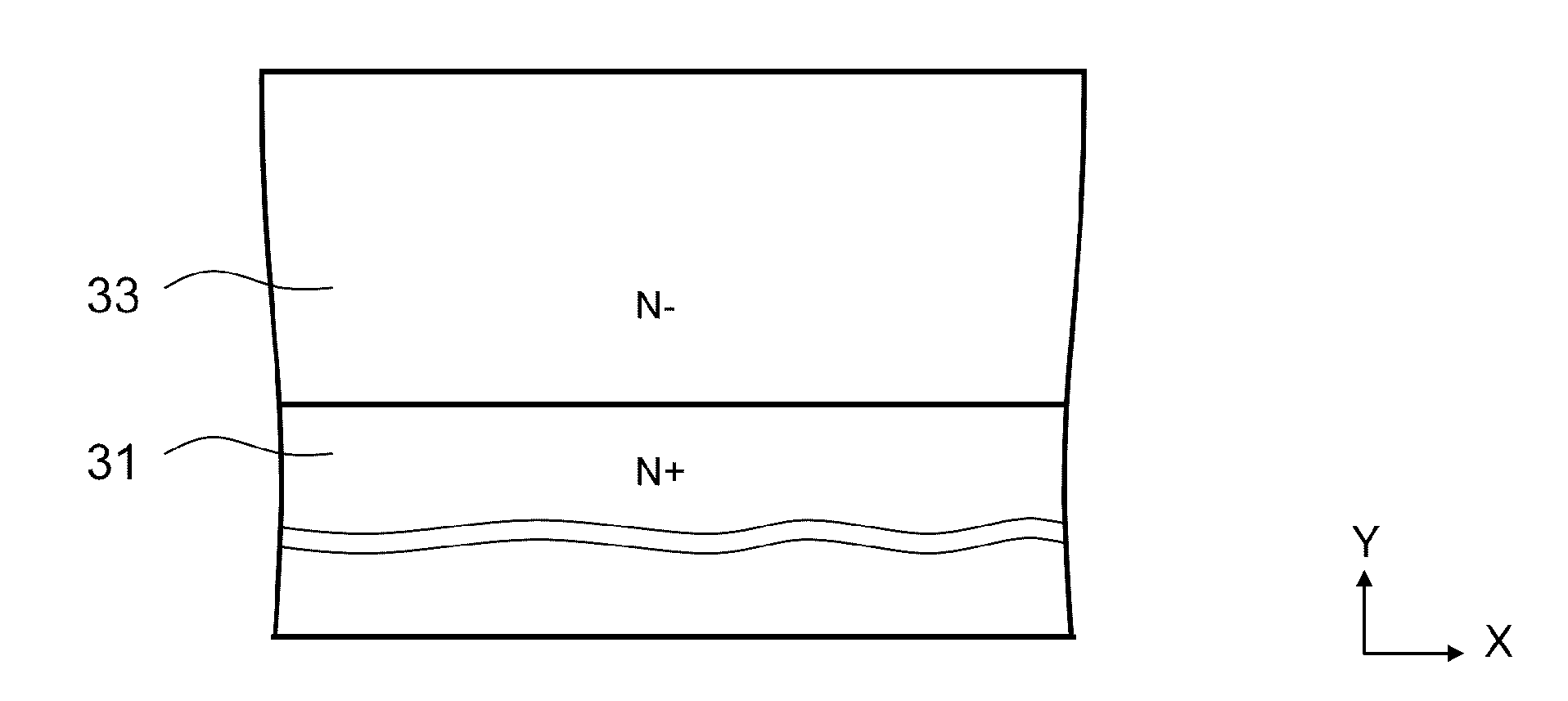

[0070] First, step S510 , providing an N-type substrate region and an N-type epitaxial region formed by epitaxial growth on the N-type substrate region.

[0071] In this step, as shown in FIG. 7, the N-type substrate region 31 can be selected as a phosphorus-doped N+ silicon substrate, and its doping concentration range can be 1×10 19 / cm 3 -1×10 21 / cm 3 ; The N-type doping concentration of the epitaxial region 33 is relatively low and substantially constant. Taking FRED with a working voltage of 1200 volts as an example, its doping concentration can be roughly set at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com