MOS type super-barrier rectifier and manufacturing method thereof

A technology of super-barrier rectifiers and manufacturing methods, applied in the field of rectifiers, can solve the problems of MOS structures such as short channels, large epitaxial resistivity, and no great advantages, so as to reduce VF value, reduce resistivity, and improve withstand voltage horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

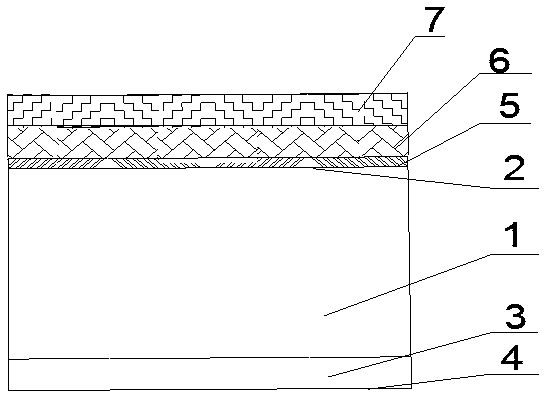

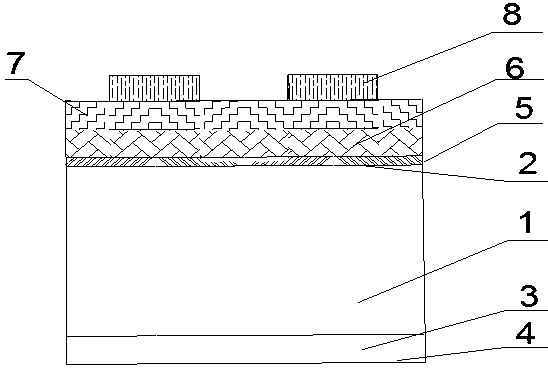

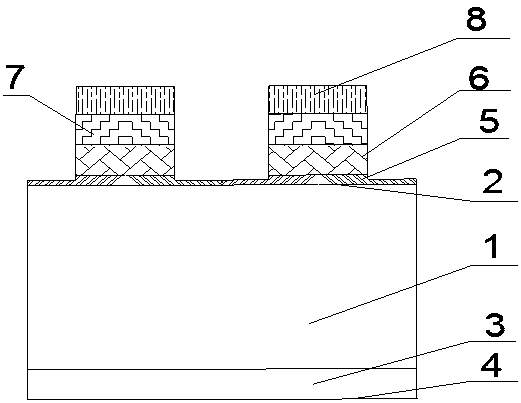

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings. What is described below is only the accompanying drawings recorded in the present invention. Those of ordinary skill in the art can also use these accompanying drawings without paying creative work. , to obtain other drawings.

[0043] The present invention shows three injection etchings, but not limited to three times, and all ideas of forming P-type regions based on multiple etching and implantation are within the protection scope of the present invention.

[0044] A MOS type super-barrier rectifier, comprising a semiconductor substrate, the upper part of the semiconductor substrate is an N-type epitaxial layer 1, the surface of which is the first main surface 2, and the lower part of the semiconductor substrate is an N-type epitaxial layer 1. + Type substrate 3, the surface of which is the second main surface 4, the first main surface 2 is provided with inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com