Recovery method for silicon carbide and polyethyleneglycol cutting fluids in waste cutting mortar for silicon wafer

A silicon wafer cutting and recycling method technology, applied in the direction of silicon carbide, carbide, lubricating composition, etc., can solve the problems of unstable quality of recycled products, affecting application, etc., and achieve the effect of light pollution and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

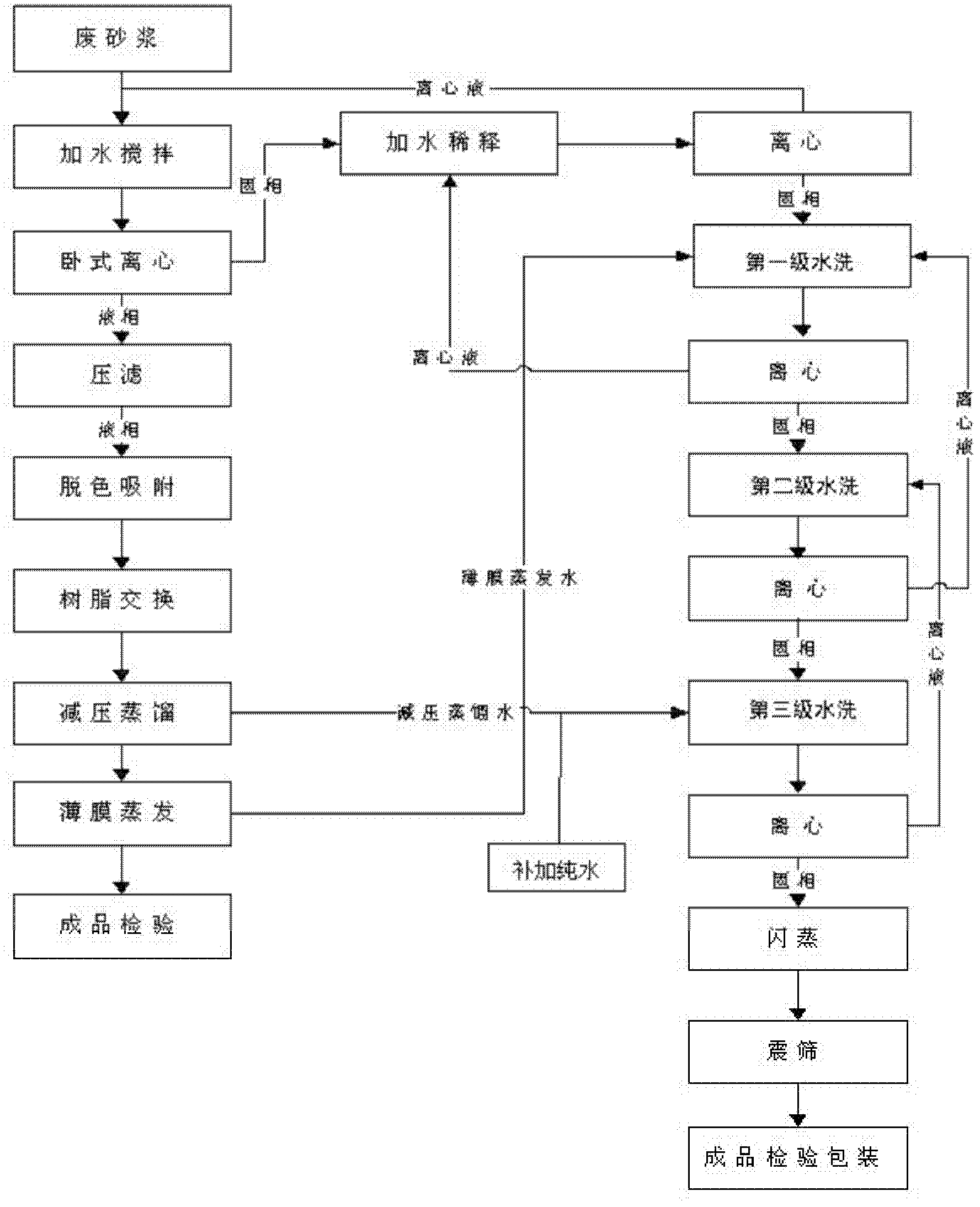

Method used

Image

Examples

Embodiment 1

[0076] According to the mass ratio of 0.5:1, water was added to 1500# monocrystalline silicon chip cutting waste mortar and stirred, and then the first stage centrifugal separation was carried out with a horizontal centrifuge at a speed of 2000r / min to obtain polyethylene glycol-containing The first-stage centrifugal liquid and the first-stage centrifugal solid particles containing silicon carbide;

[0077] According to the mass ratio of 1:1, dilute the first-stage centrifugal solid particles with water at 60°C, stir for 30 minutes, and then use a vertical centrifuge to perform second-stage centrifugal separation at a speed of 2000r / min, and obtain the second stage after 40 minutes. centrifugation of solid particles and secondary centrifugate;

[0078] Reuse the second-stage centrifugal liquid, add it to 1500# monocrystalline silicon wafer cutting waste mortar and stir, according to the mass ratio of 1:1, wash the second-stage centrifugal solid particles at 65°C for the first-...

Embodiment 2

[0086] According to the mass ratio of 0.5:1, add water to 1200# polysilicon chip cutting waste mortar and stir, and after magnetic adsorption, use a horizontal centrifuge to perform first-stage centrifugal separation at a speed of 3000r / min to obtain the first-stage centrifugate and first-stage centrifuged solid particles;

[0087] According to the mass ratio of 1:1, dilute the first-stage centrifugal solid particles with water at 70°C, stir for 60 minutes, and then use a vertical centrifuge to perform second-stage centrifugal separation at a speed of 4000r / min, and obtain the second stage after 30 minutes. centrifugation of solid particles and secondary centrifugate;

[0088] Reuse the second-stage centrifugal liquid, add it to 1200# polysilicon chip cutting waste mortar and stir it. According to the mass ratio of 1:1, wash the second-stage centrifugal solid particles at 75°C for the first-stage water washing. After 60 minutes, use a vertical The centrifuge performs the thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com