Thermoplastic elastomer material for artificial lawn and preparation method thereof

A thermoplastic elastomer and artificial turf technology, which is applied in the field of thermoplastic elastomers to achieve the effects of reducing cost, increasing low temperature resistance and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

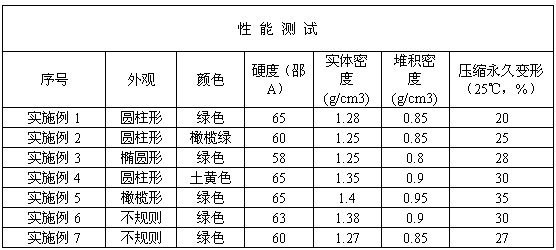

Examples

Embodiment 1

[0042] (1) Premix: 10 parts of styrene-based thermoplastic elastomer SBS (Yanshan Petrochemical 4452), 5 parts of naphthenic oil (KN4006), mixed and left for 2 hours.

[0043] (2) Premix: 1 part of PP (Yanshan Petrochemical 4220), 5 parts of VISTAMAXX (6102 of Exxon Mobil Chemical Company, USA), 4 parts of stearic acid, 20 parts of active calcium carbonate (600 mesh), anti 0.5 parts of oxygen agent (selected by mixing antioxidant 1010 and antioxidant 168 with a weight ratio of 2:1), 0.2 parts of anti-ultraviolet agent (UV-9), and 0.2 parts of green pigment (phthalocyanine green).

[0044] (3) Preparation process: Mix the premixed materials of step (1) and step (2) in a high-speed mixer (1500rpm) for 20 minutes, extrude with a twin-screw extruder at 130°C, and pelletize the strands to obtain Cylindrical particles.

[0045] According to GB / T 3511-2008, the light resistance performance of the prepared material was tested, and the surface temperature was 5°C lower than that of th...

Embodiment 2

[0047] (1) Premix: 10 parts of styrene-based thermoplastic elastomer SEBS (Kraton 1651 in the United States), mixed with 8 parts of naphthenic oil (KN4008), and left for 8 hours.

[0048] (2) Premix: 2 parts of PP (Yanshan Petrochemical 4220), 8 parts of VISTAMAXX (6102 of Exxon Mobil Chemical Company, USA), 5 parts of stearic acid, 60 parts of active calcium carbonate (activated light calcium 800 mesh) , 0.6 parts of antioxidant (the weight ratio of antioxidant 1010 to antioxidant 168 is 1:2), 0.3 parts of anti-ultraviolet agent (UV-531), 1 part of olive green (Shanghai Yipin S564B).

[0049] (3) Preparation process: Mix the premix of step (1) and step (2) in a high-speed mixer (2000rpm) for 30 minutes, extrude with a single-screw extruder at 150°C, and cut into pellets with a water ring to obtain a cylinder shaped particles.

[0050] According to GB / T 3511-2008, the light resistance performance of the prepared material was tested, and the surface temperature was 5°C lower t...

Embodiment 3

[0052] (1) Premix: 5 parts of styrene thermoplastic elastomer SBS (Yanshan Petrochemical 4452), 5 parts of SEBS (Kraton 1651), 9 parts of naphthenic oil (KN4010) and mix for 6 hours.

[0053] (2) Premix: 1 part of PE (Yanshan Petrochemical 1F7B), 6 parts of VISTAMAXX (6202 of Exxon Mobil Chemical Company, USA), 7 parts of stearic acid, 100 parts of active calcium carbonate (active heavy calcium 800 mesh) , antioxidant (antioxidant 1010 and antioxidant 168 mixed in a weight ratio of 1:1) 0.5 parts, anti-ultraviolet agent (UV-9) 0.3 parts, (phthalocyanine blue and lemon yellow weight ratio 5: 1) 2 servings.

[0054] (3) Preparation process: Mix the premix of step (1) and step (2) in a high-speed mixer (2500rpm) for 25 minutes, extrude with a twin-screw extruder at 170°C, and pelletize under water to obtain an oval shape particles.

[0055] According to GB / T 3511-2008, the light resistance performance of the prepared material was tested, and the surface temperature was 6°C lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com